Gradall 544D (9136-4003) Service Manual User Manual

Page 67

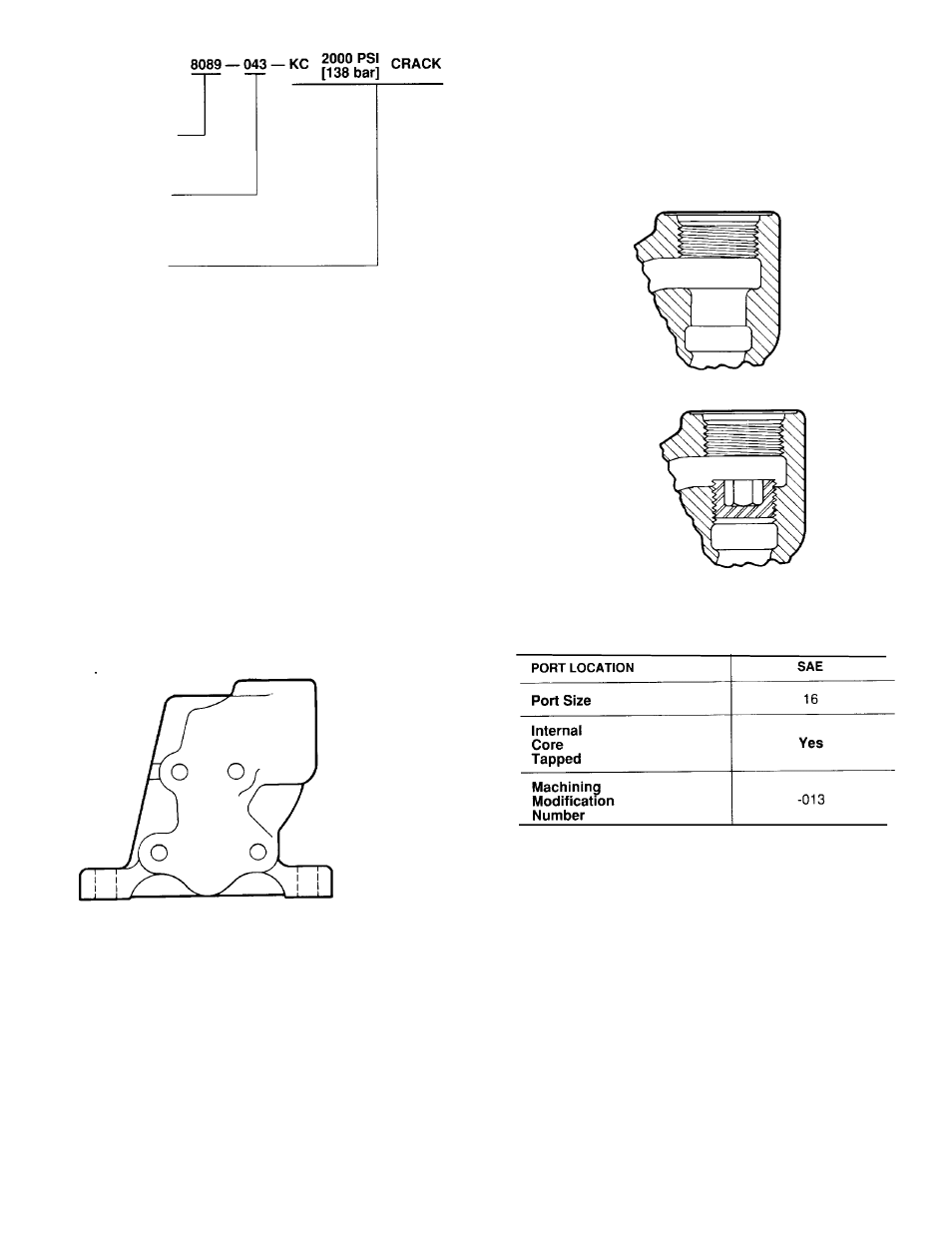

Ordering Example For Inlet Covers

*Specify:

Model number of relief valve to be used.

Relief setting required. Crack pressure is setting

when relief is passing 1 GPM [3.8 litres/min.]. Full flow

is pressure setting when relief is passing specified

GPM [litres/min].

“NR” (no relief) if plug is to be installed.

If “With no relief assembly or NR plug installed” is

specified, relief cavity will be plugged with only a

plastic shipping plug.

OUTLET COVERS

A choice of two outlet covers for the Model V40 is

available: top outlet, part no. 8090-; and end outlet, part

number 20931.

Top Outlet Cover, Part No. 8090

Standard machining provides a top outlet port for open

center applications. When the top outlet port is plugged

to provide turnaround outlet flow, the outlet port must be

located in the inlet cover.

Two options are available for the No. 8090 top outlet

cover . . . power beyond and closed center applications.

For power beyond, the core between the open center

and exhaust passages is tapped and plugged. The top

outlet port becomes the power beyond port. The tank

outlet port must be located in the inlet cover. When the

Basic Casting

Part No.

Machining

Modification

Number

Relief Valve

Details*

1.

2.

3.

4.

top power beyond port is plugged, the Valve Assembly

may be used in a closed center application.

For future field conversion from standard open center to

either power beyond or closed center applications, the

outlet cover may be ordered with the core tapped but

not plugged.

Options For the No. 8090 Outlet Cover

Standard Machining for Open Center

Power Beyond Option

Use the following porting chart to determine the

proper machining modification number for the No.

8090 outlet cover.

3-3