Removing the complete boom assembly – Gradall 544D (9136-4003) Service Manual User Manual

Page 332

9.5

E

XTEND

C

HAIN

R

OLLER

Removal of the roller is just a matter of slacking off the chain adjustment hardware on the

top of the boom, removing the chain from the clevis, removing and reinstalling the roller.

Adjust the extend chains per instructions in Section 4.

H

OSE

T

AKE-UP

A

SSEMBLY

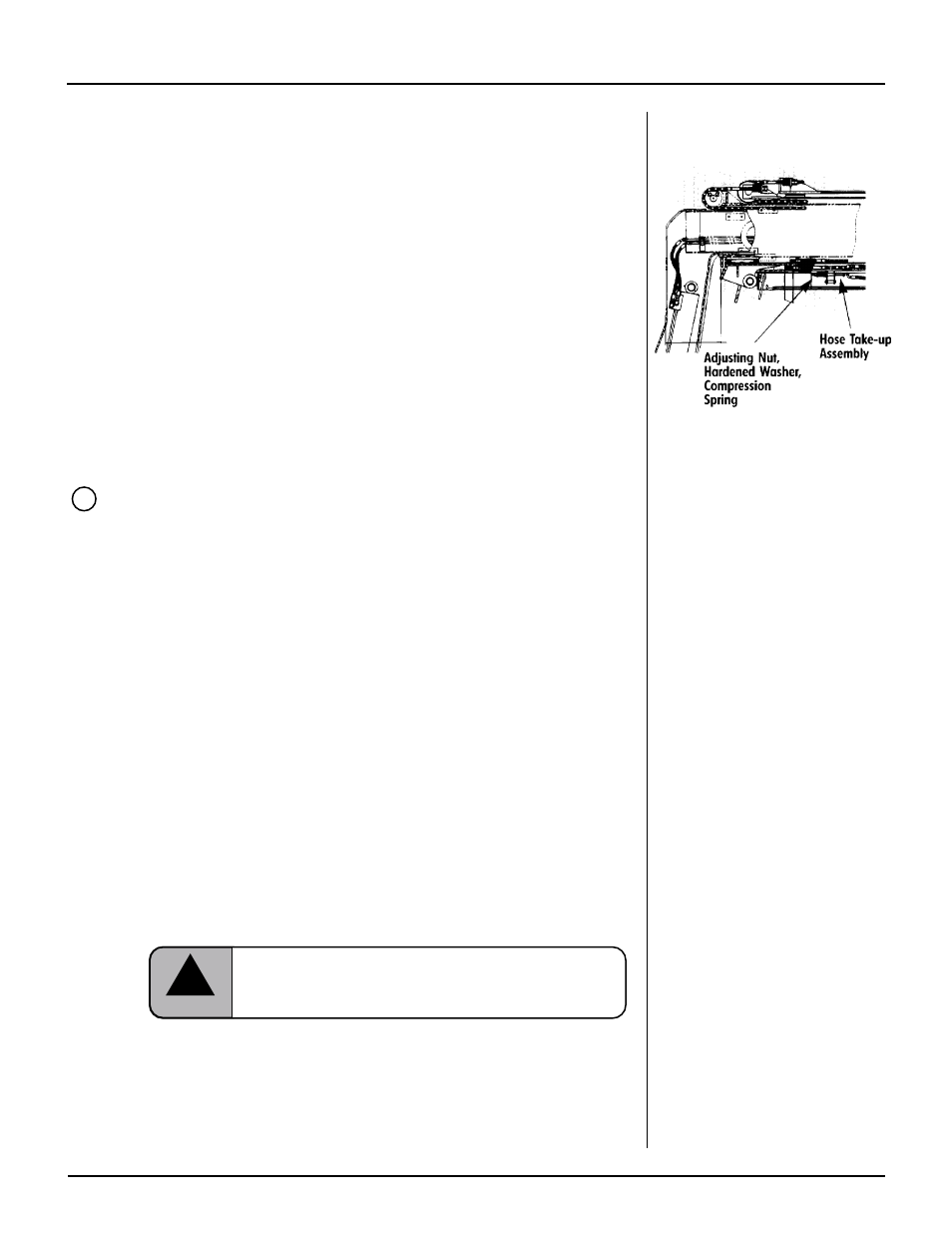

The Hose Take-Up assembly keeps tension on the hoses inside boom-section 1 that feed

the Hydraulic Sub-Assembly. This prevents the hoses moving uncontrolled whenever the

boom is extended and/or retracted.

The adjusting nut is tightened against the compression spring sufficient to hold tension.

When properly adjusted, there should be 1" from the back of the jam nut to the end of

the hose take-up assembly threads. Torque the jam nut to 100 ft-lb. using LOCTITE 242

on the threads.

R

EMOVING

T

HE

C

OMPLETE

B

OOM

A

SSEMBLY

Preparation

Position the handler in a safe, level, open area well away from personnel and

equipment. Apply the park brake, shift the forward/reverse lever to Neutral and

turn the wheels straight forward.

Turn off the ignition, remove the keys and chock all wheels.

Procure lifting tackle and crane of sufficient size to lift the boom assembly

safely. Note! The assembly weighs approximately 8220 lb.

Install a log line to the front of the boom to help guide it once it clears

the machine.

Fasten slings to boom-section 1 between the crowd cylinder and the boom at the

balance point.

Take the weight off the boom assembly.

Removal

Identify and tag all hydraulic hoses (and any electrical cables).

Separate, plug and cap all hoses. Separate any electrical cables. With the cylinder

hoses blocked off, the boom sections will be locked in position, preventing run-out.

Carefully remove pins from the compensation and lift cylinders.

Confirm that the crane still has the weight of the boom.

Carefully remove the boom base pin.

Lift the boom assembly free of the machine and place it in a designated

work area.

9D

Make sure cylinders do not full uncontrolled to their free position.

This could injure personnel and/or damage components.

!

CAUTION

Note!

Whenever one or more boom

sections must be separated, the best

approach is to remove the complete

assembly from the machine before

attempting separation. The assembly

can then be placed on stanchions

(horses) at a normal working height

(Removing assemblies while the

boom is still installed on the

machine would necessitate working

off ladders or platforms)

F

ORM

N

O.

29702

lllll

544C/544D B

OOM

M

AINTENANCE