A: f, Gradall, Hart – Gradall 544D (9136-4003) Service Manual User Manual

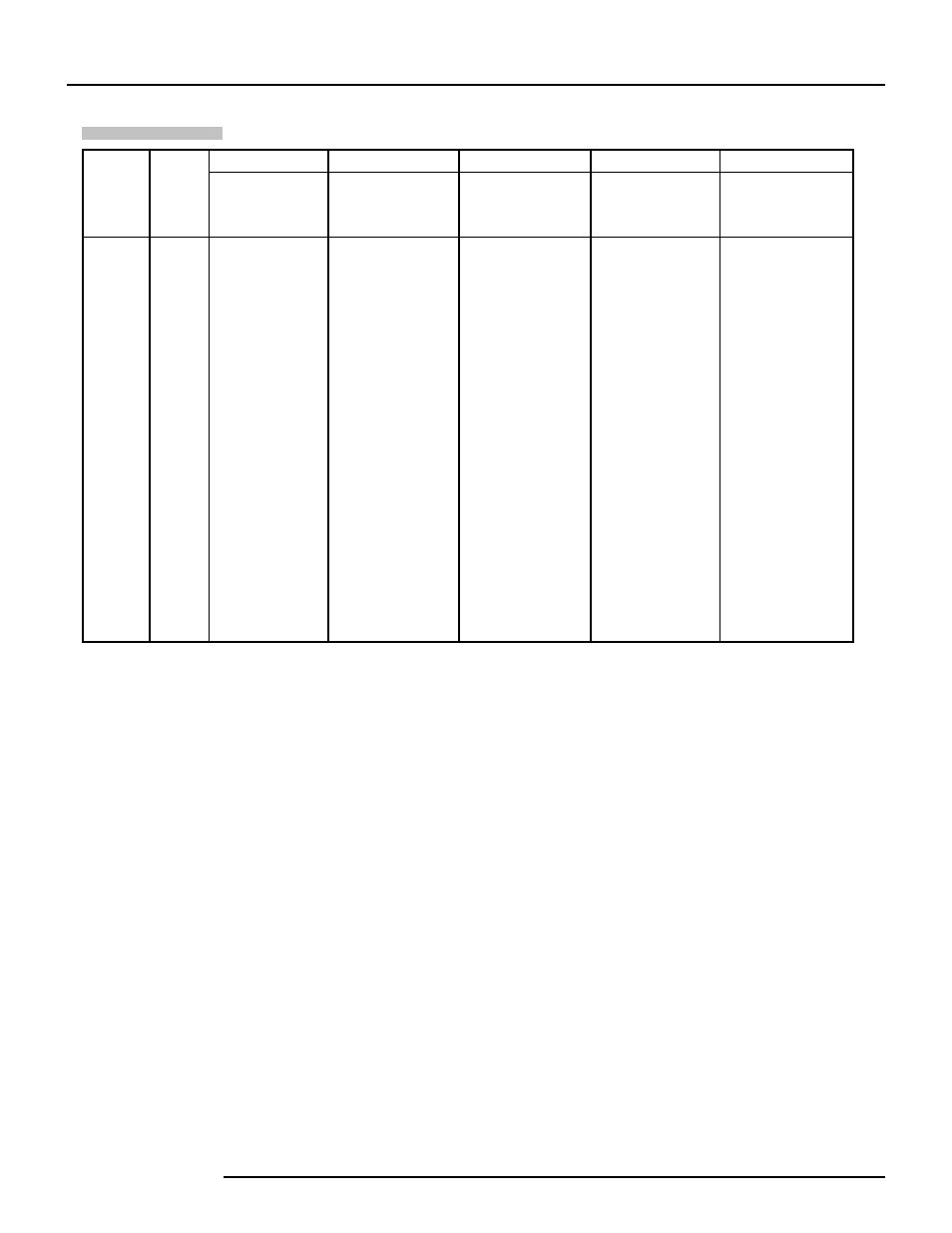

Page 355: Ppendix, Astener, Orque

NOMINAL

SIZE

M 2.0

M 2.5

M 3.0

M 3.5

M 4.0

M 5.0

M 6.0

M 6.3

M 8.0

M 10.0

M 12.0

M 14.0

M 16.0

M 20.0

M 24.0

M 30.0

M 36.0

M 42.0

Stress

Area

(mm

2

)

2.1

3.4

5.0

6.8

8.8

14.2

20.1

22.6

36.6

58.0

84.3

115.0

157.0

245.0

353.0

561.0

817.0

1120.0

CLASS 4.6

CLASS 8.8

CLASS 9.8

A

PPENDIX

A: F

ASTENER

T

ORQUE

C

HART

M

ETRIC

F

ASTENERS

CLASS 10.9

CLASS 12.9

400 Megapascals

Min. Tensile Str.

(Nm)

0.14

0.28

0.51

0.80

1.18

2.39

4.05

4.78

9.84

19.49

33.99

54.10

84.40

164.64

284.66

565.49

988.24

1580.54

(ft.-lb.)

0.10

0.21

0.37

0.59

0.87

1.76

2.99

3.53

7.26

14.37

25.07

39.90

62.25

121.43

209.95

417.08

728.89

1165.75

830 Megapascals

Min. Tensile Str.

(Nm)

0.37

0.76

1.35

2.13

3.15

6.36

10.81

12.76

26.25

51.99

90.68

144.32

255.18

439.24

759.43

1508.64

2636.49

4216.66

(ft.-lb.)

0.27

0.56

1.00

1.57

2.32

4.69

7.97

9.41

19.36

38.35

66.88

106.45

166.08

323.96

560.13

1112.72

1944.58

3110.05

900 Megapascals

Min. Tensile Str.

(Nm)

0.40

0.82

1.47

2.31

3.41

6.90

11.72

13.84

28.46

56.38

98.33

156.49

244.17

476.28

823.48

1635.88

2858.85

4572.29

(ft.-lb.)

0.30

0.61

1.08

1.70

2.52

5.09

8.65

10.21

20.99

41.58

72.52

115.42

180.09

351.29

607.37

1206.56

2108.58

3372.35

1040 Megapascals

Min. Tensile Str.

(Nm)

0.52

1.06

1.88

2.96

4.38

8.86

15.05

17.77

36.54

72.38

126.25

200.93

313.50

611.52

1057.31

2100.38

3670.62

5870.59

(ft.-lb.)

0.38

0.78

1.39

2.18

3.23

6.54

11.10

13.11

26.95

53.39

93.12

148.20

231.22

451.03

779.83

1549.16

2707.31

4329.93

1220 Megapascals

Min. Tensile Str.

(Nm)

0.61

1.24

2.21

3.47

5.14

10.59

17.66

20.84

42.87

84.91

148.10

235.70

367.76

717.36

1240.30

2463.91

4305.92

6886.66

(ft.-lb.)

0.45

0.92

1.63

2.56

3.79

7.67

13.02

15.37

31.62

62.63

109.23

173.85

271.24

529.10

914.80

1817.29

3175.88

5079.34

Note!

To check Gradall torque values, set

the torque wrench of 95% of rated

torque value and check the

fastener. If the torque wrench

releases before the fastener moves,

assume that fastener torque is

correct. When setting Gradall

torque values, use values given on

the chart, not exceeding

allowances.

GRADALL

GRADALL