Reinstalling the complete boom assembly, Gradall – Gradall 544D (9136-4003) Service Manual User Manual

Page 333

9.6

R

EINSTALLING THE

C

OMPLETE

B

OOM

A

SSEMBLY

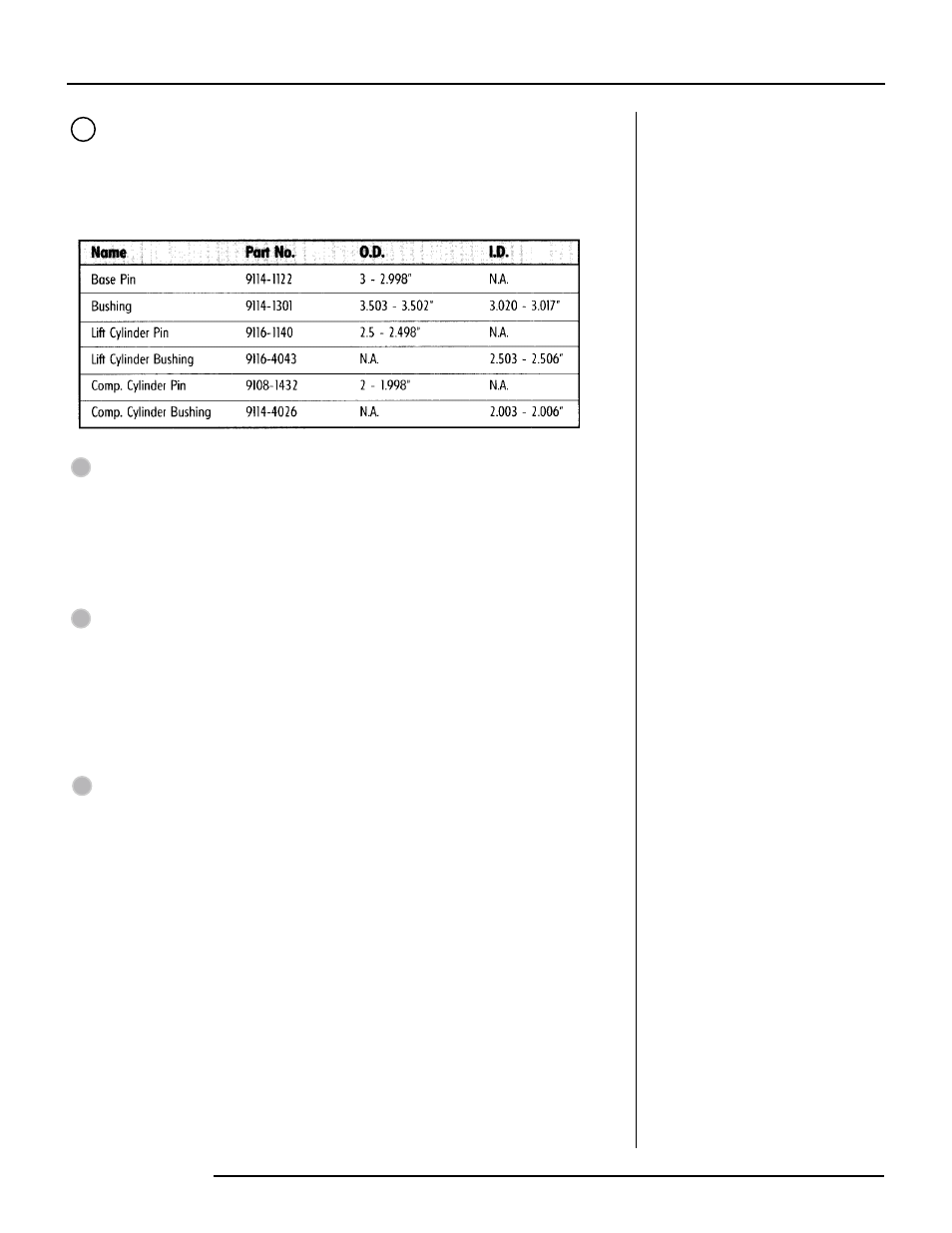

The assumption is made that all four boom sections are reassembled into one assembly as

when removed from the machine. Before reassembly of the boom, check the bores, pins

and bushings for damage. Repair as needed. Also check diameters of pins and bushings.

The dimensions of the pins and bushings used to fasten the boom assembly to the

machine frame are as follows:

Preparation

Re-check that the machine is still safely secured.

Procure lifting tackle and crane and re-lash the boom assembly at a balance point.

Install the tackle between the crowd cylinder and the boom.

Note! Make sure a tag line is installed.

Make a test lift to ensure that the rigging is hooked up correctly to lift the boom

assembly in a balanced mode.

Installation

Lubricate all pins and bushings.

Lift the boom assembly into position on the machine.

Line up the base pin holes, insert pins and lock in place.

Install lift cylinders onto the boom, insert pins and lock in place.

Install the compensation cylinder into the boom and lock in place.

Reconnect separated hoses and cables. Torque hose fittings per Appendix B.

Remove the rigging from the machine.

Test

Carefully start up the machine and operate the boom assembly full cycle at

least 10 times.

Check for hydraulic leaks; repair as necessary.

Cycle boom circuits 10 more times to be certain all air is purged from the system.

Final-adjust boom wear pads, extend & retract chains, hose take-up assembly

and any other area that needs to be serviced.

9E

1.

2.

3.

4.

1.

2.

3.

4.

5.

6.

7.

1.

2.

3.

4.

→

→

→

→

→

→

→

→

→

→

→

→

→

→

→

GRADALL

GRADALL