Chain inspection and replacement, Gradall, Hain – Gradall 544D (9136-4003) Service Manual User Manual

Page 319: Nspection and, Eplacement

6.0 C

HAIN

I

NSPECTION AND

R

EPLACEMENT

!

DANGER

When inspecting chains, observe the following guidelines:

Remove the chain(s) from the machine.

Clean the chain(s) thoroughly with a suitable cleaning agent.

Check the chains for wear on link plate edges.

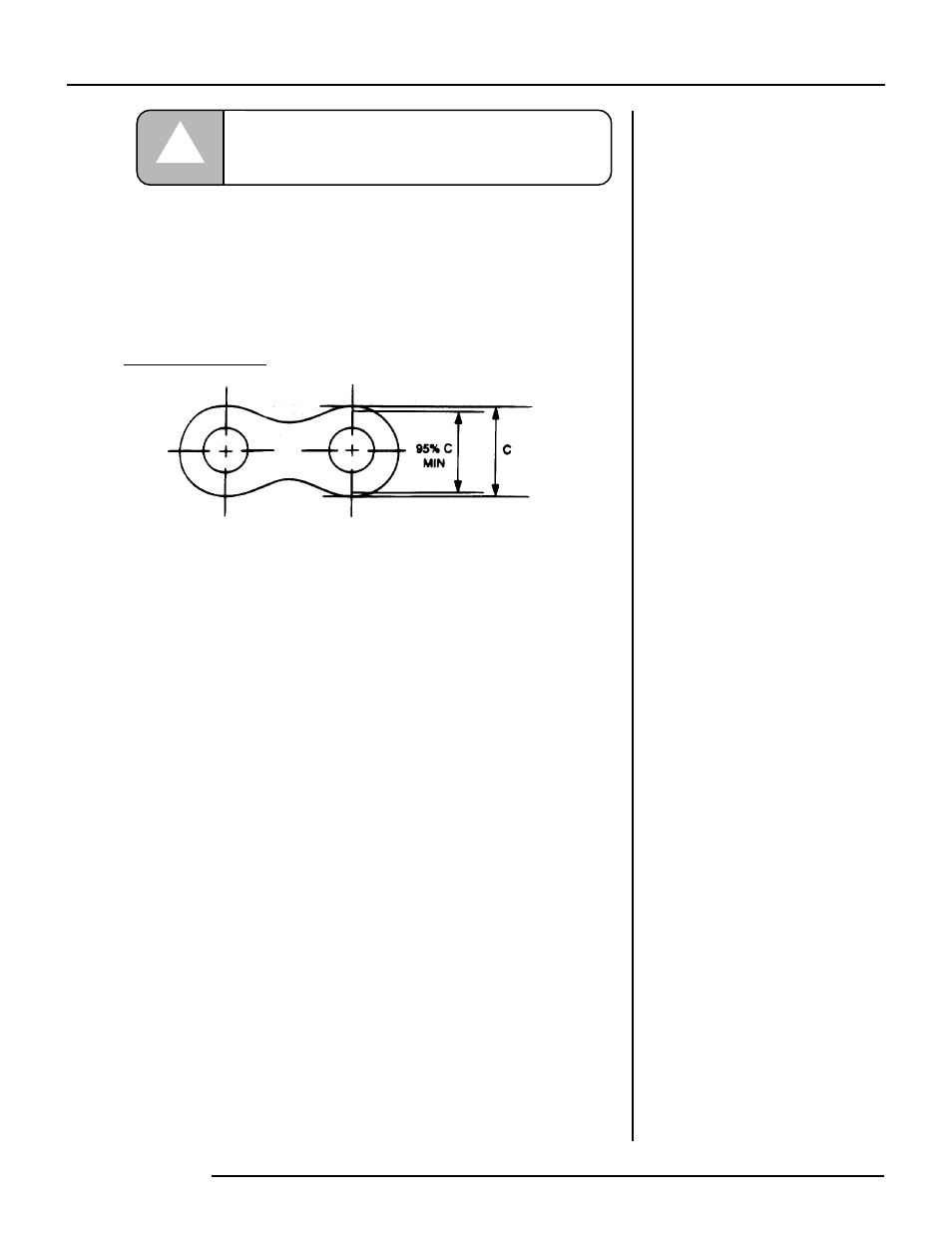

Maximum reduction of plate depth should not exceed 5% of total plate depth when new.

See dimension C below

C

HAIN

L

INK

D

IMENSIONS

Dimensions of the chain links used on the Gradall 544C-10 and 544D:

See dimension C above

Chains should be scrapped if they have:

Cracked link plates

Damaged/worn bearing pins

Outer plates with elongated holes (which present the danger of the plate sliding

free of the rivet head with subsequent chain breakage).

Chains should also be examined for evidence of damage or corrosion.

Chains do not wear evenly along the full length. Maximum wear is generally confined to

those sections which articulate under load; i.e. where the chain passes over a pulley or a

shim.

It is impossible to determine the useful life of a worn chain by checking its overall length

against the normal overall length of a new chain. Worn chains must be examined over

their full length and then measured on that portion of the chain which exhibits most

serious signs of wear. This must be done when the chain is lying on a flat surface under

sufficient tension to take up all the slack.

The overall length of new chains used on the 544C-10 and 544D is:

An elongation of 2% represents the end of the useful life of a chain. In other words, when

P/N 9116-3037 is at or above a length of 14' 4 1/8" and P/N 9116-3036 is at or above a

length of 16' 9", they should be scrapped. Chains should also be scrapped if the links do

not meet tolerances indicated on the chain wear gauge (Gradall P/N 9116-4084).

In the interests of safety, all Gradall Material Handler owners

should check all chains at regular intervals, not exceeding 6 months

(1200 hours).

1.

2.

3.

Size New

3/4"

1"

Allowable Minimum

22/32"

61/64"

Chain Part No.

9116-3037

9116-3036

l

l

l

Chain Part No.

9116-3037

9116-3036

Pitch

3/4"

1"

Length

14' 3/4"

16' 4 7/8"

NOTE!

We recommend the use of a chain

wear gauge (Gradall P/N 9116-

4084) to perform this operation.

GRADALL

GRADALL