Boom wear pad adjustments, Djustments – Gradall 544D (9136-4003) Service Manual User Manual

Page 306

F

ORM

N

O.

29702

l

l

l

l

l

544C/544D B

OOM

M

AINTENANCE

3.0

B

OOM

W

EAR

P

AD

A

DJUSTMENTS

l

l

l

l

l

l

l

l

l

l

G

ENERAL

To maximize boom service life, wear pads must be correctly adjusted at all times. The

following Service Notes are a general guide for properly adjusting boom wear pads:

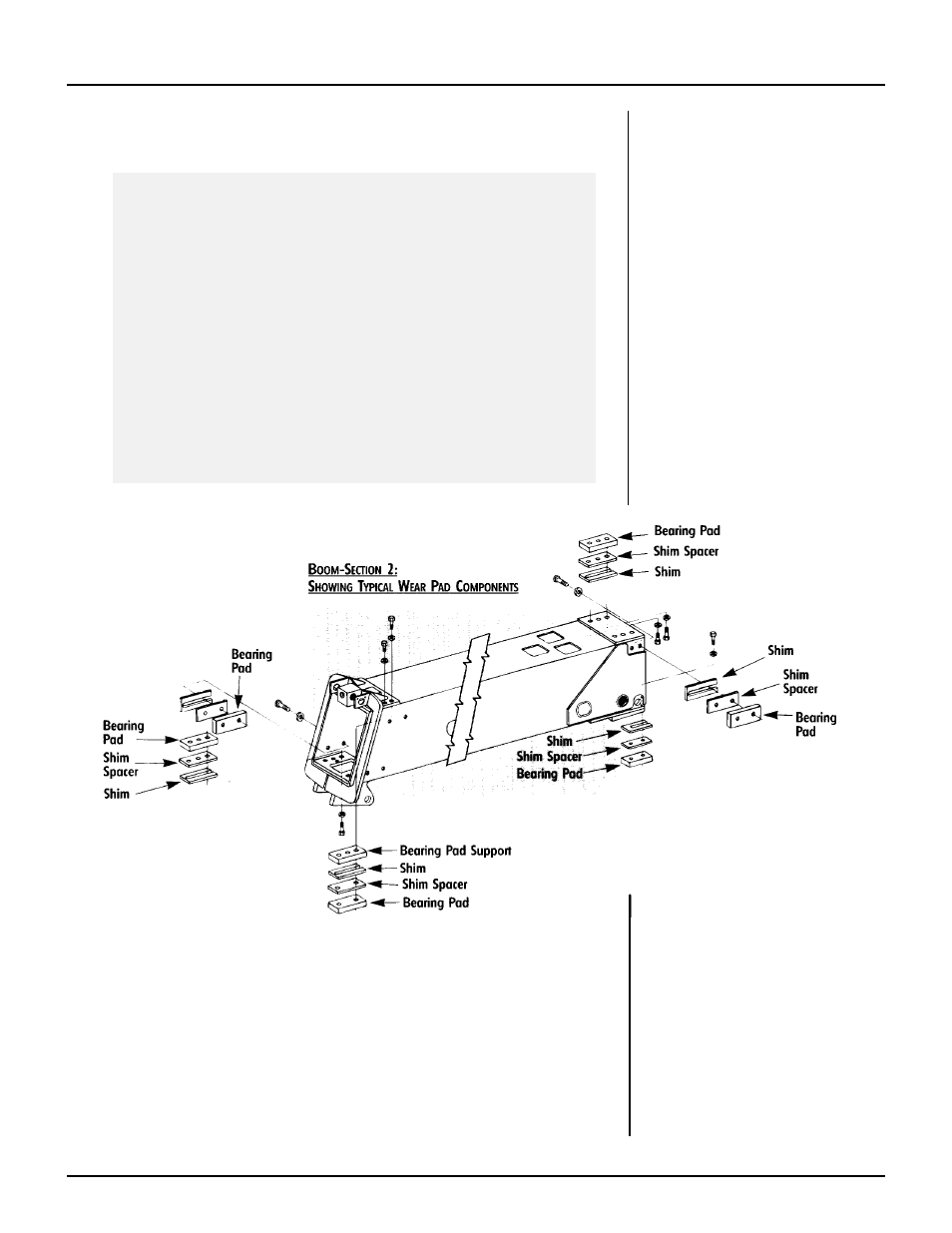

Familiarize yourself with all bearing pad components (See Note! below)

Add bearing pad shims & spacers as required to shim boom within 1/16" of tight fit

Boom-sections 2, 3 and 4 should be evenly centered to outer boom-section 1

(shim packs should be equal side-to-side and top-to-bottom)

Insert spacers between the pad and the shim

Make sure no pad sits directly on the slotted surface of a shim

Bolts must not extend beyond the chomfer on the bearing pad. The length of pad

bolts depends on the number of shims used

Spread Mystilk Tetrimoly grease (Gradall P/N 1440-4595) (or equivalent) on

all bearing pads and pad sliding surfaces

Apply LOCTITE 242 (Gradall P/N 1440-3364) to all bolt threads

Bearing pad bolt torques are:

3/8" bolts 32-37 ft-lb.

112" bolts 76-86 ft-lb.

Hollow 3/8 bolts 20-25 ft-lb.

Booms should not be adjusted so tight that the lube is wiped off the sliding path

NOTE!

See pages 3.2 to 3.5 for

comprehensive guide to number

and location of bearing/wear pad

components on each boom

section.