HP 750 User Manual

Page 194

750C

750C

Plus

755

CM

9-16

Print Quality

C4705-90000

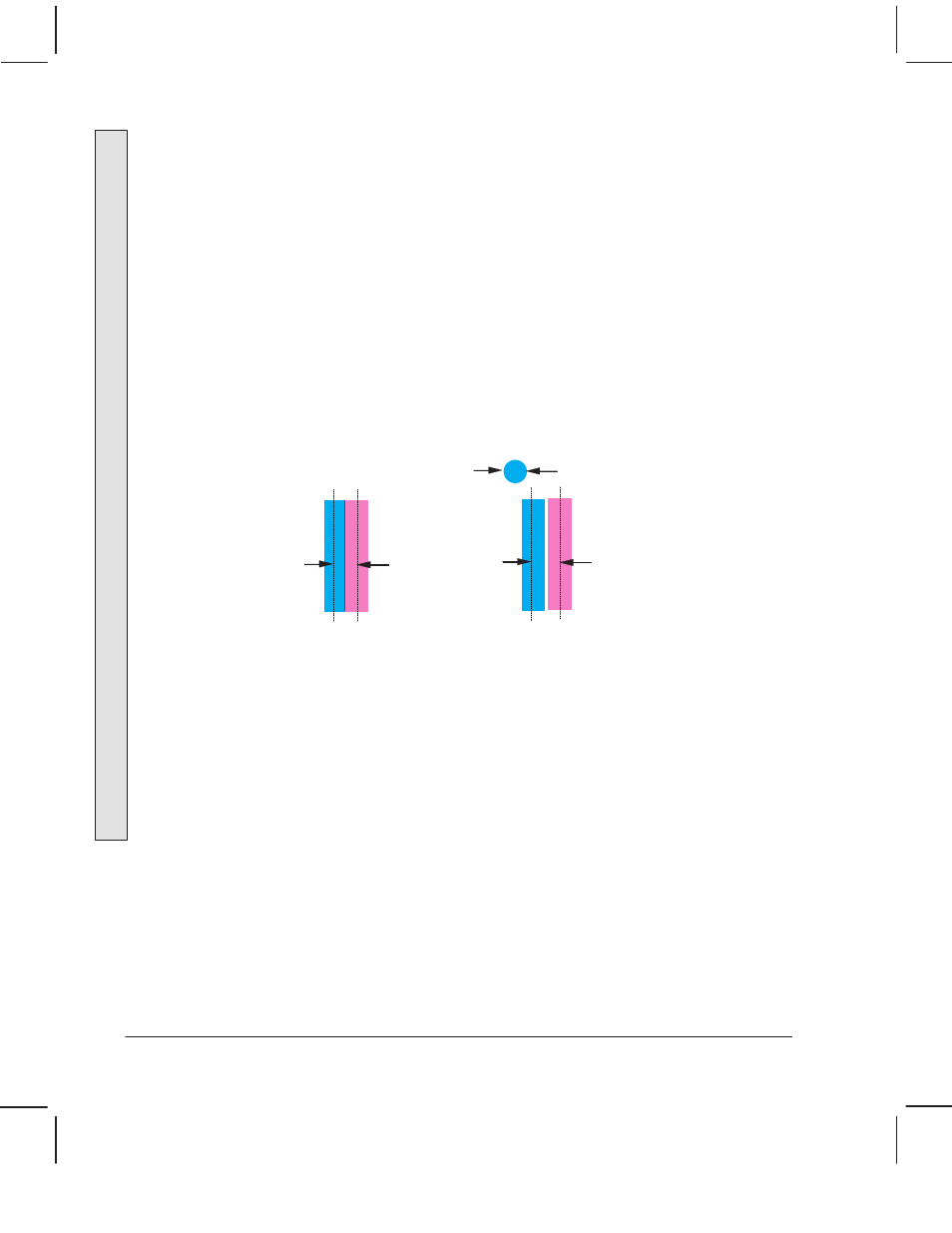

Pattern 3 (on the CAD color diagnostic pot) contains vertical and horizontal lines ofthe four

basic colors (cyan, magenta, yellow and black). This is a worst case situation, which provides

qualitative information.

Pattern 4 (on the CAD color diagnostic pot) includes one square and horizontal and vertical

lines in red (yellow plus magenta), blue (cyan plus magenta), and green (yellow plus cyan). The

horizontal and vertical lines can be used to verify whether the alignment between the

cartridges used to print them is within the required specification. The lines are one pixel in

thickness. If the plot is printed on matte film" media the dot size is approximately 3.33 mils

diameter (the same value as the alignment specification). Focus on one horizontal or vertical

blue line (see figure below), that is generated by two lines of cyan and magenta. If there is a

misalignment between the two cartridges, bigger than 3.33 mils, the lines will be this distance

apart. In this case, there will be a white line between the magenta and the cyan, as the dots of

each color will not come in contact. (The distance will be bigger than the dot size.) When there

is a blue line between the magenta and the cyan, then the distance between the lines is smaller

than 3.33 mils, hence, the alignment error is within the required specifications.

Dot size 3.33 mils

(Film / Glossy)

Alignment error

3.33 mils

In Spec (limit)

Alignment error

< 3.33 mils

Out of Spec

Corrective Actions

Ifthe penĆtoĆpen alignment error is out ofspecification:

D Perform the pen alignment test using white media ' page 8Ć40.

D Perform the lineĆsensor calibration (details ' page 7Ć5) and perform the pen alignment

test again.

D Replace all cartridges.

D Replace the carriage ' page 6Ć34.

D Troubleshoot the EEROM and the Main PCA.