HP 750 User Manual

Page 192

9-14

Print Quality

C4705-90000

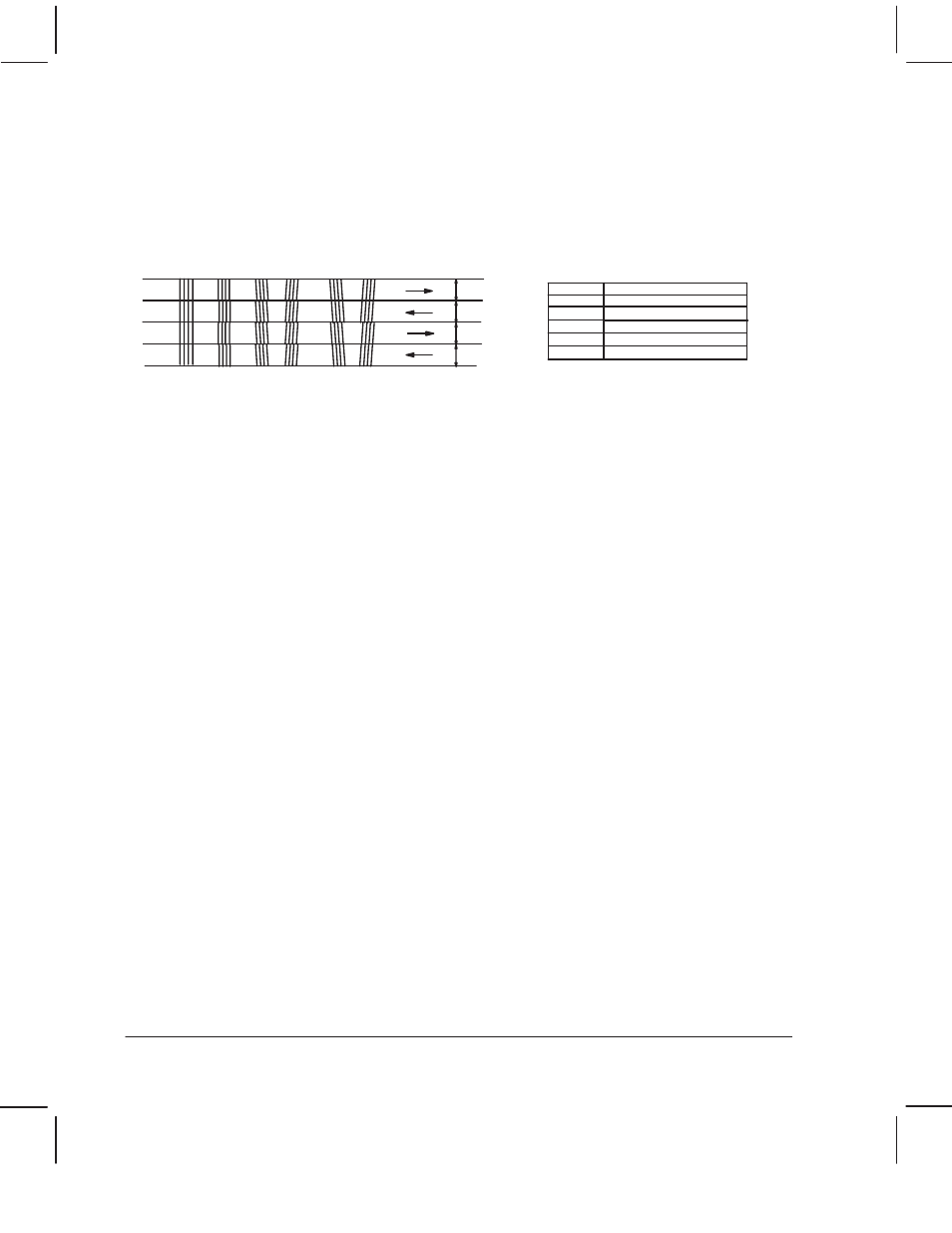

Vertical Line Straightness (VLS)

If you look very closely at a vertical line produced by the plotter, you will notice that it's not

perfectly straight. This is because, between consecutive swaths, there is usually some error in

accuracy: a vertical line in one swath may be a little to the left or a little to the right of the

line plotted in the previous swath. Depending on the causes of the error, lines that are

supposed to be vertical may appear as shown below:

Combined error

Swath

W

idth

Swath

W

idth

Swath

W

idth

Swath

W

idth

Carriage Swath

Direction

1

2

3a

3b

4a

4b

1

No error

2

Bidirectional error

3a

Theta–Z error

3b

Theta–Z error

4a

Combined error

4b

Bidirectional Error

Error numbered 2 above is called a bidirectional error. If you print the same plot using a

unidirectional print mode, the error should not appear. (Print modes ' 9Ć5.)

This error can occur for various reasons, including:

D EncoderĆstrip slots are damaged or dirty.

D Friction between carriage bushings and slider rod:

ThetaĆZ Error

Errors numbered 3a and 3b are called ThetaĆZ errors. They appear when the rows of nozzles

on a cartridge are not perpendicular to the carriage axis (YĆaxis).

This error can occur for various reasons, including:

D Badly seated cartridge.

D Faulty cartridge.

D Faulty carriage.

Corrective Actions

D Perform the pen alignment test using white media ' page 8Ć40.

Avoid the use of glossy media as the black pen cannot be aligned using this type of media.

D Perform the lineĆsensor calibration ' page 7Ć5 and perform the pen alignment test again.

D Replace all cartridges.

D Replace the carriage ' page 6Ć34.

D Troubleshoot the EEROM and the Main PCA.

Nozzle CheckĆOut

Note that, to print the nozzle checkĆout, the central nozzles of the cartridges have been used.

So the numbers of the nozzles do not correspond to the actual numbers. If you want to test

all the nozzles of the cartridges, you should perform the "Nozzle Print Test" ' page 8Ć32.

Misdirection Pattern

The main purpose of this plot is to qualitatively validate the penĆtoĆpen alignment. It also

provides information on the pen performance, as it includes a nozzle checkĆout and area fill.