Verifying the probe zero at a later time – Checkline TI-MINIMAX User Manual

Page 83

MINI-MAX Ultrasonic Bolt Tension Monitor

value should be very small. Therefore, if the zero is re-calculated and the delta is

very large, something else has gone wrong and the user should become

suspicious of the how well the probe zero was performed.

If we consider the initial probe zero value constant, as the hardware and cal bars

have not been replaced, the future verifications should always show an

elongation value of +/- 0.0001”, in order to be considered “In Spec”. If the probe

zero is out of spec, the user should make adjustments only to the physical

temperature setting in the MINI-MAX. In other words, the primary reason the

probe zero is out of spec is because the physical temperature of the probe zero

calibration standards has changed.

If the accessory temperature sensor is

being used, the sensor will automatically adjust the physical temperature

and the MINI-MAX should be “In Spec” and displaying an elongation value

of 0.0000” +/- .0001”. The next section outlines the verification procedures.

Verifying the Probe Zero at a Later Time

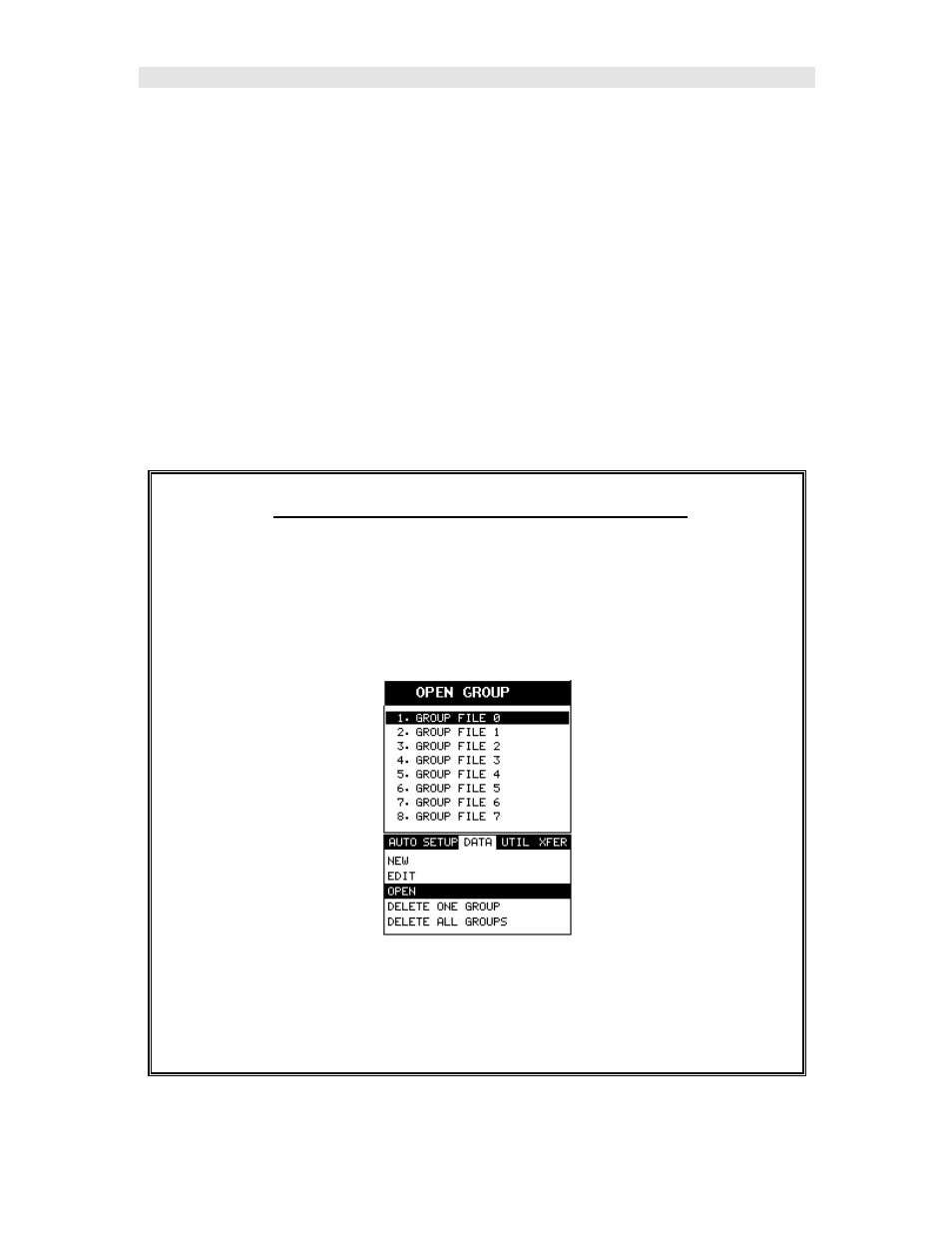

1) Press the

MENU key once to activate the menu items tab. Press the

MENU key multiple times to tab right, and the ESC key multiple times to

tab left, until the

DATA menu is highlighted and displaying the submenu

items.

2) Use the

UP and DOWN arrow keys to scroll through the sub menu

items until

OPEN is highlighted.

3) Press the

ENTER key to display the Open Group List Box.