0 setpoints, 1 batch and continuous setpoints, Setpoints – Rice Lake 320IS Plus Intrinsically Safe Digital Weight Indicator - Installation Manual User Manual

Page 62

56

320IS Plus Installation Manual

7.0

Setpoints

The

320IS Plus

indicator provides eight programmable setpoints for control of both indicator and external

equipment functions.

Control of external equipment is available only if an I/O Module is connected to the

320IS Plus

.

Setpoints are configured to trip based on specified conditions; tripping the setpoint can be used to request

indicator functions (print, tare, accumulate) or to change the state of a digital output controlling external

equipment.

Weight-based setpoints are tripped by values specified in primary units only.

Programmable setpoints require the optional I/O module. See Section 9.0 on page 72 for more information on the

I/O module.

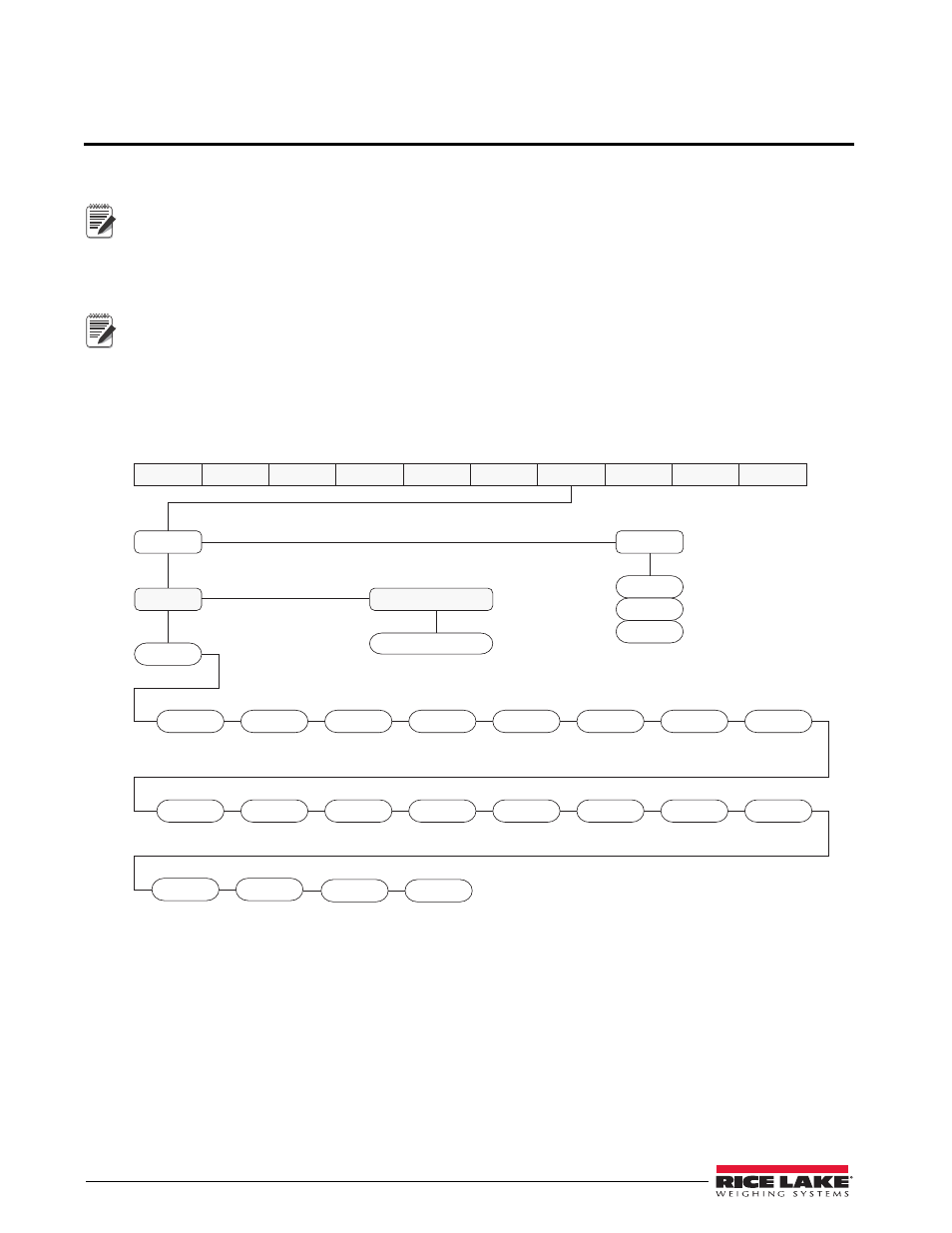

Figure 7-1 shows the general structure of the SETPTS menu. See Section 3.2.7 on page 32 for a detailed

description of the SETPTS menu. The eighteen setpoint kinds are described in Table 7-1 on page 57.

Figure 7-1. SETPTS Menu

7.1

Batch and Continuous Setpoints

320IS Plus

setpoints can be either continuous or batch setpoints.

Continuous setpoints

are free-running: the indicator constantly checks the input channel for the setpoint

value at each A/D update. If the input channel weight reading matches the setpoint value, the indicator sets

the corresponding digital output on.

Batch setpoints

are active one at a time, in an ordered sequence. The

320IS Plus

can use batch setpoints to

control up to eight separate batch processing steps. A digital output associated with a batch setpoint is on

until the setpoint condition is met, then latched for the remainder of the batch sequence.

Note

Note

PAUSE

RESREL

XXXXXXX

SETPTS ALGOUT

DIGIN

PROGRM PFORMT

SERIAL

CALIBR

CONFI

G

FORMAT

VERS

Same as SETPT1

SPCFG

BATCHN

OFF

AUTO

MANUAL

SETPT2 – SETPT8

GROSSP

NETSP

OFF

DELAY

WAITSS

SETPT1

COUNTR

AUTJOG

COZ

NMOTON

NRANGE

BATPRO

TIMER

CONCUR

–GROSS

–NET

ACCUM

+RELSP

–RELSP

%RELSP