Unpacking the eddy current brake – Dynojet 250i: Pit Installation Guide User Manual

Page 33

I N S T A L L A T I O N

Eddy Current Brake

Version 4

In Ground Model 200iP/250iP Motorcycle Dynamometer Installation Guide

2-11

U

NPACKING

THE

E

DDY

C

URRENT

B

RAKE

1

Remove the four bolts securing the brake to the crate.

2

Remove the retarder connector plates, if present.

3

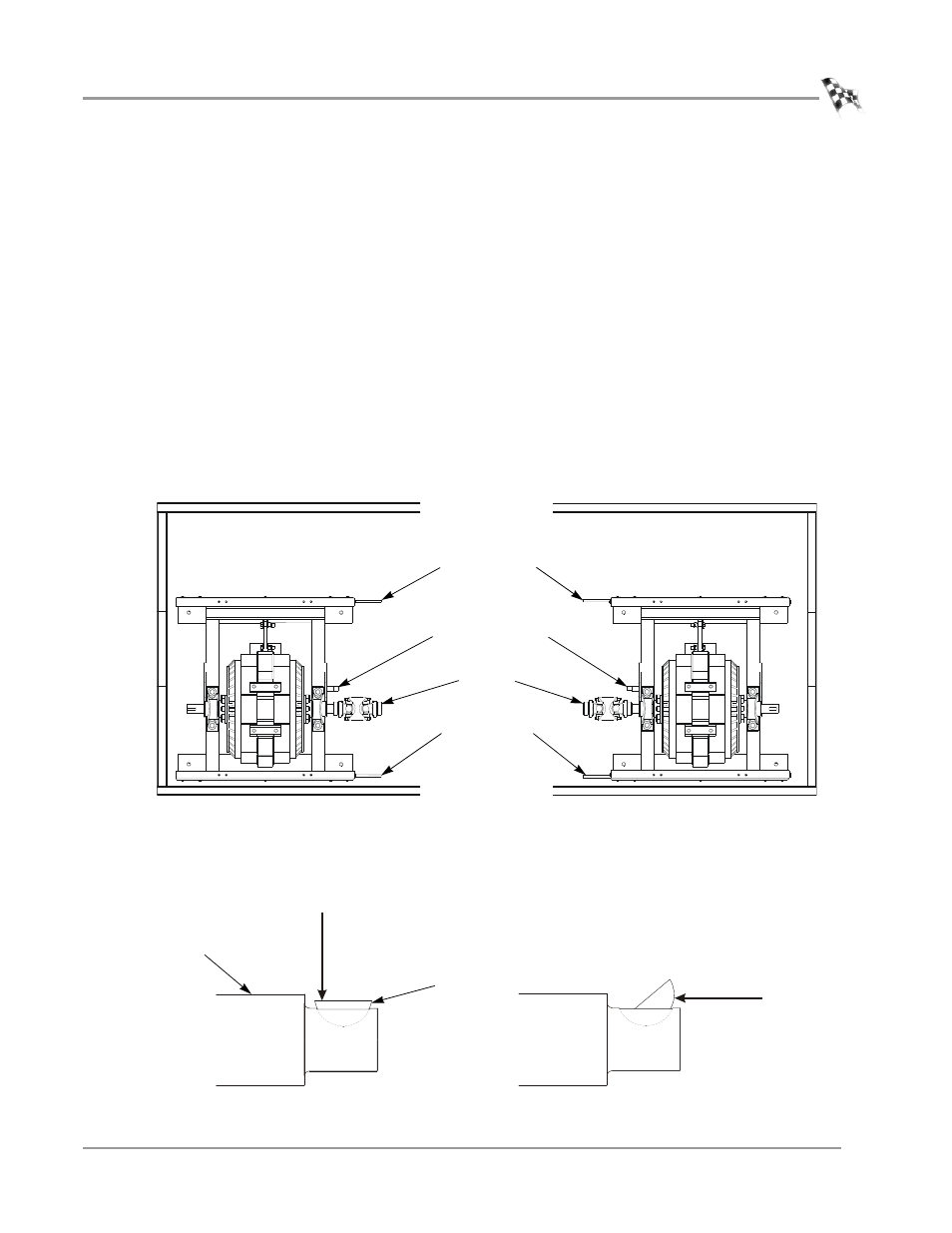

Determine if the brake is to be mounted on the left or right side of your dyno.

Note: This installation has been designed for the eddy current brake to be

installed on the left side of the dyno. Contact Dynojet for information regarding

installation on the right.

Make the following adjustments to the eddy current brake only if you want to

mount the brake on the opposite side of the dyno that it is currently set up for.

• Move the coupler and key to the other side of the brake.

To remove the key, use a punch and a hammer to apply pressure in the

direction of the arrows shown in Figure 2-6.

• The retarder connector plates (removed in step 2) will need to be moved to

the other side of the brake once the brake is installed in the pit.

• Move the temperature sensor to the other side of the brake.

Figure 2-5: Left or Right Side Brake Set Up

Figure 2-6: Removing the Key

EB221

eddy current brake set up for left side

installation

eddy current brake set up for right side

installation

driveline

temperature sensor

connector plate

connector plate

apply force using

hammer and punch

apply force using

hammer and punch

shaft

key