Rockwell Automation MinPak Plus DC Drives Kits User Manual

Page 9

8

ning procedures common to all Regenerative MinPak

Plus controllers. Most of the guidelines listed here must

be followed in order to achieve an efficient layout.

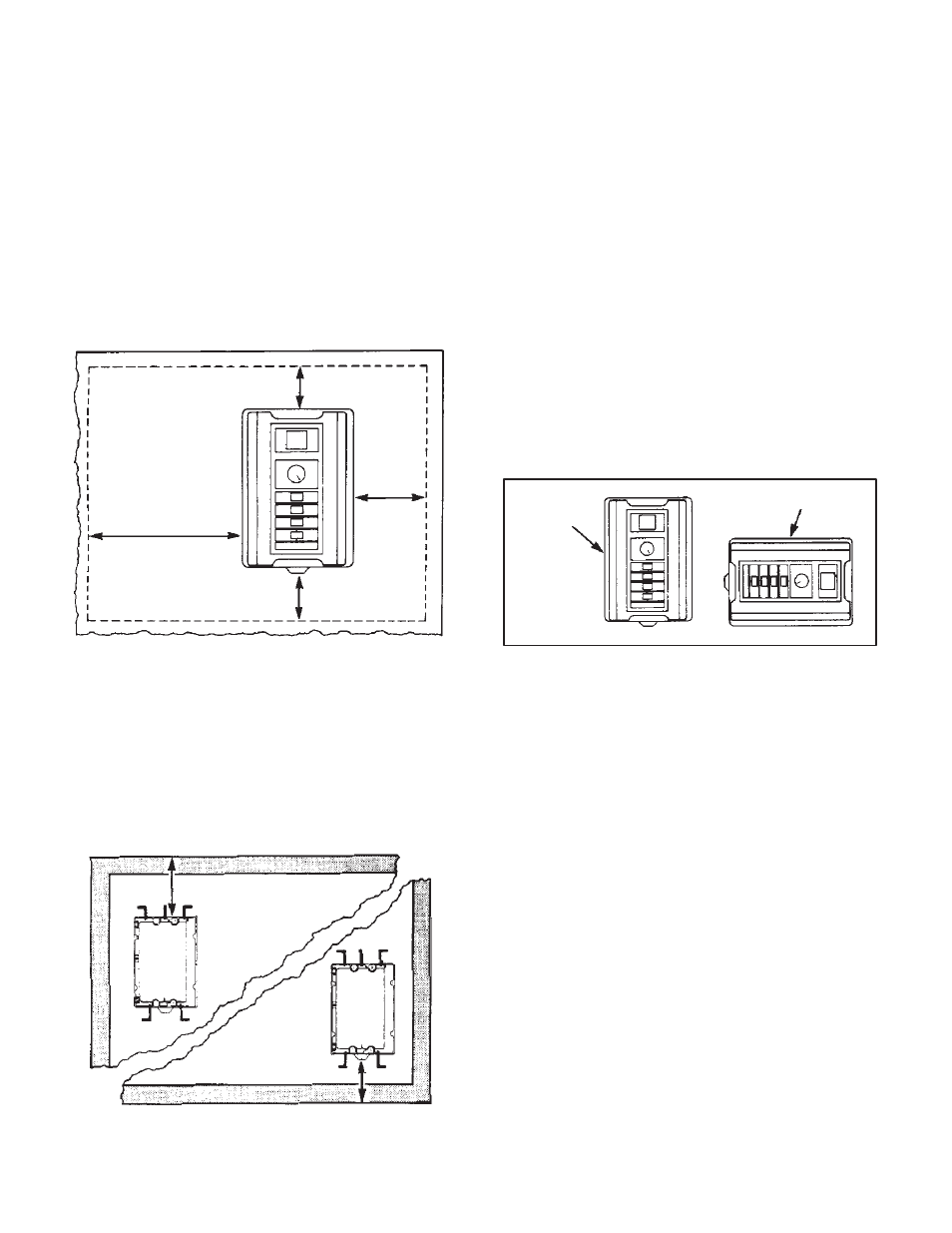

Guideline 1 Ċ The Regenerative MinPak Plus controller

is designed primarily as a wallĆ or panelĆmounted unit. It

is to be hung within 10

°

of vertical with the rear of the

Chassis firmly resting against the mounting surface. (Do

not position the Chassis on a horizontal surface.)

Guideline 2 Ċ It is necessary to leave at least a 2Ćinch

(50 mm) clearance around the three unhinged sides of

the Chassis. This unobstructed area allows for proper

air circulation through the fins of the heat sink. (Refer to

Figure 3.1.)

Guideline 3 Ċ Since the controller's Cover is hinged,

additional clearance must be provided on the fourth side

of the Chassis. (Refer to Figure 3.1.)

Do not

place

devices

in this

area.

11 in.

(275 mm)

2 in.

(50 mm)

2 in.

(50 mm)

2 in.

(50 mm)

Figure 3.1 - Open PanelMinimum Mounting Distances

Guideline 4 Ċ If mounting the controller within a larger

enclosure, do not place it directly in a corner. Leave at

least 8 inches (200 mm) from the top or 6 inches (150

mm) from the bottom of the enclosure. Also leave 8 inĆ

ches (200 mm) between the enclosure side wall and the

unhinged side of the controller. (Refer to Figure 3.2.)

Heat builds up at the cabinet's top and may exceed the

permissible inside ambient temperature upper limit. At

the cabinet's bottom, the unit must be high enough to alĆ

low air to flow upwards.

8 in.

(200 mm)

6 in.

(150 mm)

Figure 3.2 - Enclosure Mounting Minimum Distances

Guideline 5 Ċ Regardless of the above placement

guidelines, the user is responsible for providing ambient

temperatures that meet the controller's specifications.

For units mounted on an open panel or wall and using

the standard Cover, this range is 0

°

to 40

°

C (32

°

to

131

°

F). For units mounted in a ChassisĆonly configuraĆ

tion in a larger cabinet, this range is 0

°

to 55

°

C (32

°

to

131

°

F). Relative humidity must be kept between 5 and

95% without condensation if a Cover is not used.

Guideline 6 Ċ Keep in mind that the wells, which proĆ

vide incoming and outgoing wire channels, are designed

to accept threaded male conduit couplings. Plan controlĆ

ler placement on the wall or panel to allow for conduit

runs. Note also that two wells are 3/4"Ć14 pipe threads,

and three wells are 1/2"Ć14 pipe threads.

Guideline 7 Ċ Because of the diagonal design of the

heat sink, the Regenerative MinPak Plus controller ChasĆ

sis may be mounted in one of two orientations: first, with

the side containing three conduit wells at the top and, seĆ

cond, with the same side at the right. (The Cover, if used,

will swing to the left or, alternately, upward.) Refer to FigĆ

ure 3.3.

hinges

hinges

Figure 3.3 - Mounting Orientations

Guideline 8 Ċ If the controller is to be mounted in a largĆ

er enclosure and if the NEMA rating of that enclosure is

adequate, there is no absolute reason to use a Cover,

which is shipped as standard. (This assumes that a ReĆ

mote Operator Station is used.) However, the environĆ

ment of the application should be carefully considered

before making this decision.

Using the Regenerative MinPak Plus controller without a

Cover demands that the ambient environment around

the Chassis be relatively clean, free of flammable or

combustible vapors, chemical fumes, oil vapor, steam

and/or excessive dirt and moisture.

Guideline 9 Ċ If the controller is placed in a larger encloĆ

sure, do not place it so that the Cover, if used, cannot

swing open at least 90

°

minimum. Allowing for the full

110

°

swing aids subsequent installation and troubleĆ

shooting. (Note that the Cover may swing to the left or

upward, depending on the mounting orientation. Refer to

Figure 3.3.)

Guideline 10 Ċ Do not route the tachometer feedback

signal cable, if used, in the aĆc or dĆc conduits. Use a

dedicated steel conduit fixed in the proper well. Also use

the specified wire for this function.