Rockwell Automation MinPak Plus DC Drives Kits User Manual

Page 10

9

Guideline 11 Ċ The controller requires a singleĆphase

power supply that provides either 115 VAC or 230 VAC

at 50/60 Hz. If correct voltage is not available, it will be

necessary to install a transformer between the power

supply and the controller.

WARNING

DO NOT OPERATE THE REGENERATIVE MINĆ

PAK PLUS CONTROLLER ON POWER SUPĆ

PLIES WITH AVAILABLE SHORTĆCIRCUIT CURĆ

RENTS IN EXCESS OF 1000 AMPERES FOR

RATINGS OF 1 HP, OR LESS, AND 5000 AMĆ

PERES FOR RATINGS GREATER THAN 1 HP.

DAMAGE TO EQUIPMENT AND PERSONAL INĆ

JURY MAY OCCUR.

Guideline 12 Ċ Although autoĆtransformers may step

up and step down aĆc power supply voltage, they do not

isolate the drive system from the aĆc line. Users should

consider using an isolation transformer if the application

conditions warrant it.

Guideline 13 Ċ The plant power supply must be of suffiĆ

cient current capacity to support input current requireĆ

ments of the controller. (Refer to the drive's nameplate for

correct input power information.)

Guideline 14 ĊThe National Electrical Code requires

that a 2Ćpole, fused disconnect switch be installed on the

incoming aĆc line ahead of the controller to provide

branch circuit protection.

Fuses for this disconnect switch should be chosen from

Table 3.A. They should be dualĆelement. slow blow type,

or Class K5 or RK5.

Note that the standard POWER ON/OFF circuit breaker

is a doubleĆpole circuit breaker designed to provide

overcurrent protection for the internal Power Cubes conĆ

taining the power semiconductors. In addition, it is an

electrical disconnect. However, the N.E.C. or local codes

may still require that a fused disconnect device be used.

An existing branch switch may provide adequate protecĆ

tion.

It is recommended that the disconnect switch be placed

within easy reach of operating and maintenance personĆ

nel. Do not place it inside a surrounding enclosure since

cabinet doors may be locked. (Consult your local codes.)

Guideline 15 Ċ If an isolation or autoĆtransformer is

used ahead of the controller, the disconnect switch

should be placed on the aĆc power line between the powĆ

er source and the transformer primary. Again, use a

fused disconnect switch. (Do not use a circuit breaker

type switch because of the high inrush of transformer

equipment.) Refer to Table 3.A for sizes and types.

Guideline 16 Ċ An isolation transformer is not necesĆ

sary unless the application conditions require one. HowĆ

ever, its use provides distinct advantages. With an isolaĆ

tion transformer:

D Personal injury is guarded against should accidenĆ

tal contact be made with an electrical conductor

from the drive.

D AĆc power line disturbances, or transients, are miniĆ

mized by an isolation transformer, thereby reducing or

eliminating damage to other solidĆstate equipment

powerĆconversion components in the controller and

other userĆequipment on the same aĆc line.

D The transformer provides electrical isolation beĆ

tween the aĆc power lines and the drive motor.

Damaging currents may be eliminated in instances

where a dĆc output accidentally becomes

grounded in a unit where the aĆc electrical system

is grounded.

For detailed information, refer to Paragraph 3.10.

Guideline 17 Ċ If a threeĆconductor incoming aĆc line is

being used. it is necessary to connect the GND (green/

ground) wire to the terminal provided on the Chassis.

Ring type connectors are recommended. The user must

be sure that the ground wire is connected to the plant

ground at the source.

Guideline 18 Ċ If the controller is mounted in an encloĆ

sure that is not grounded, it is necessary to provide for

a ground. (Personal injury may result if this practice is not

followed.)

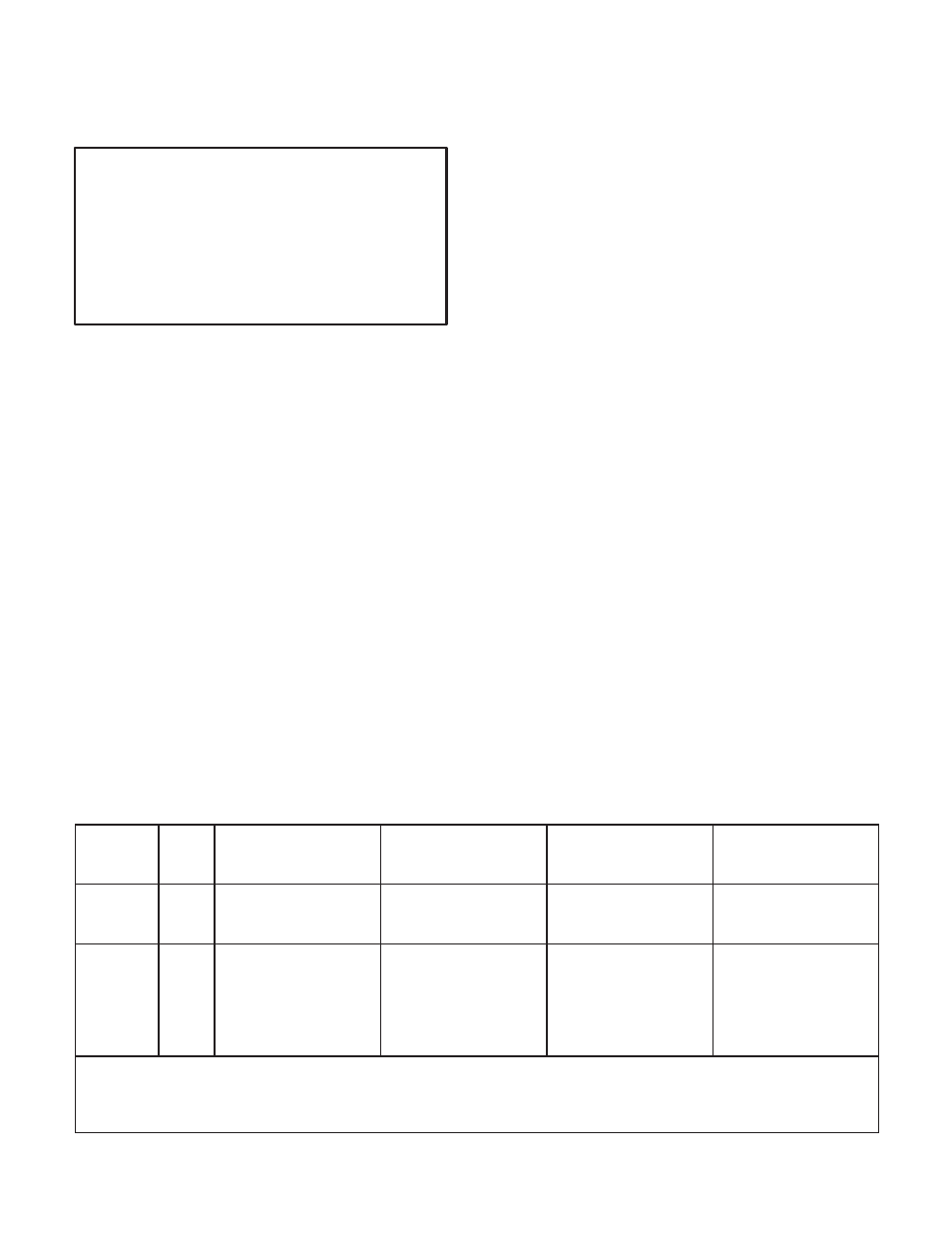

Table 3.A - TYPICAL WIRE. FUSE SIZES➀

HP

VAC

AĆC POWER

(min. size/insul.)

DĆC ARMATURE

(min. size/insul.)

DĆC DRIVE➁

(min. size/insul.)

DISCONNECT

FUSE SIZE➂

(amps)

1/4

1/3-1/2

3/4

115

115

115

No. 14 AWG 75

°

C

No. 14 AWG 75

°

C

No. 12 AWG 75

°

C

No. 14 AWG 75

°

C

No. 14 AWG 75

°

C

No. 12 AWG 75

°

C

No. 14 AWG 75

°

C

No. 14 AWG 75

°

C

No. 14 AWG 75

°

C

ă8

15

20

1/2

3/4-1

1Ć1/2

2

3

5

230

230

230

230

230

230

No. 14 AWG 75

°

C

No. 14 AWG 75

°

C

No. 12 AWG 75

°

C

No. 12 AWG 75

°

C

No. 10 AWG 75

°

C

No. ă8 AWG 90

°

C

No. 14 AWG 75

°

C

No. 14 AWG 75

°

C

No. 12 AWG 75

°

C

No. 12 AWG 75

°

C

No. 10 AWG 75

°

C

No. ă8 AWG 90

°

C

No. 14 AWG 75

°

C

No. 14 AWG 75

°

C

No. 14 AWG 75

°

C

No. 14 AWG 75

°

C

No. 14 AWG 75

°

C

No. 12 AWG 90

°

C

ă8

15

20

25

35

60

➀

Copper wire recommended.

➁

Permanent magnet motors do not require field supply.

➂

Fuses must be dualĆelement, timeĆdelay (slowĆblow) type, or U.L. Class K5 or RK5