Rockwell Automation MinPak Plus DC Drives Kits User Manual

Page 32

31

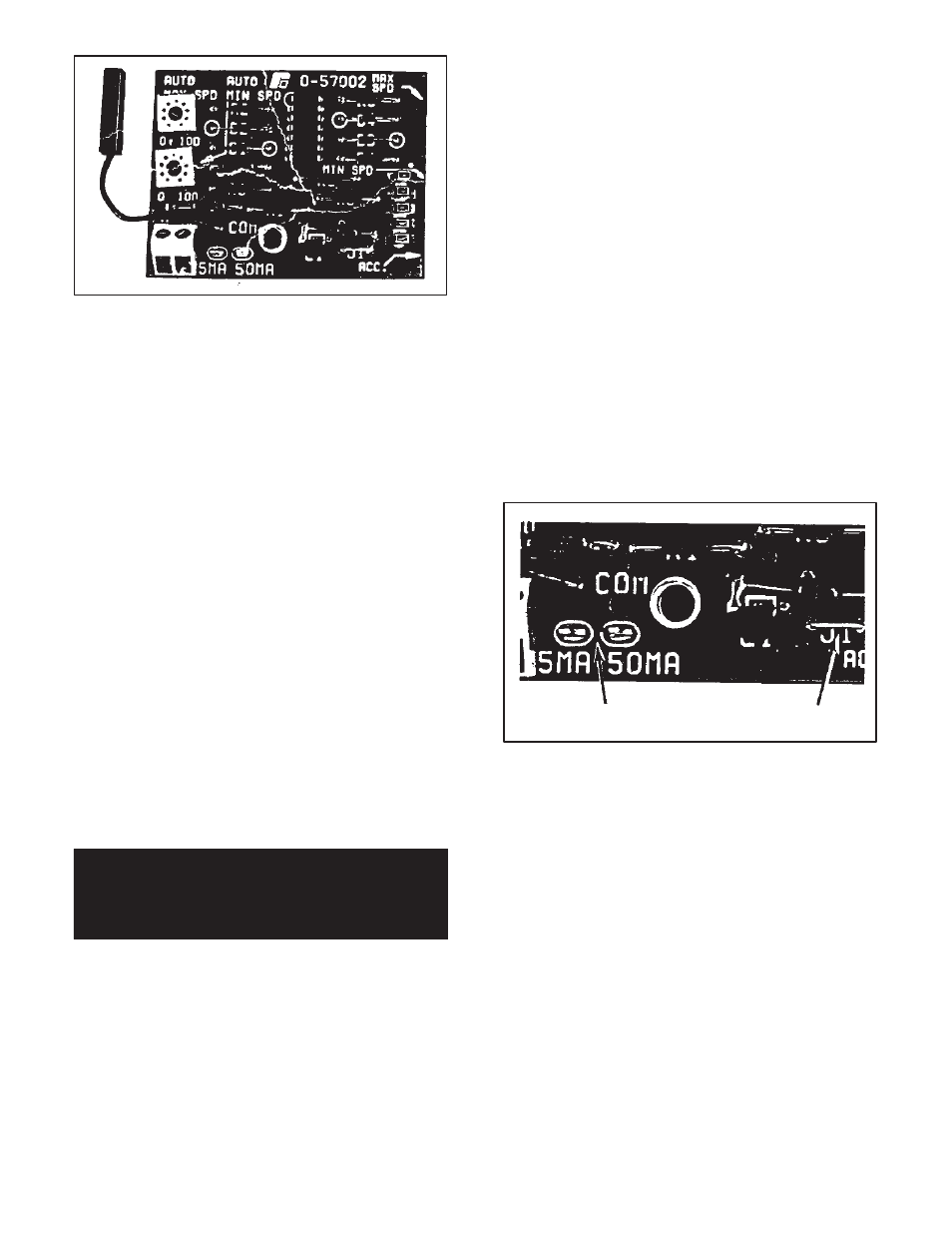

Figure 6.9 - Instrument Interface Kit

The Auto Minimum Speed potentiometer on the Module

can be set so that the drive runs at a preset minimum

speed (zero to 50%) with a minimum output signal from

the process instrument. The Auto Maximum Speed poĆ

tentiometer on the Module can be set so that the drive

runs at 50% to base speed with a maximum output signal

from the instrument. Other relationships within these paĆ

rameters are also possible, and they allow operation

over a larger speed range than the 5:1 range provided by

the process controller.

The Kit contains a Module that has a jumper that must be

connected by the user to select one of two maximum inĆ

put signals: 5 mA or 50 mA. There is also a mounting

screw. The Kit may be used alone to provide full, autoĆ

matic drive control, or it may be used with an optional

AUTO/MANUAL selector switch on the Operator Control

Station. This switch may be used to manually override

the external dĆc signal. (In the MANUAL position, the

drive follows the SPEED potentiometer on the Station.)

The user supplies the required lengths of specified signal

wire. (Refer to Table 6.C.) A process instrument controlĆ

ler, or other transducer with a dĆc milliampere output, is

also required.

NOTE: If the Operator Control Station contains an AUTO/

MANUAL selector switch, it is necessary to remove jumpĆ

er J1 from the Instrument Interface Module and J4 (Local

Station only) on the Regulator Module. (Refer to Figure 6

10.) Do this before placing the Module on the Regulator

Module.

DANGER

APPLICATION MUST NOT RELY ON ZERO

SPEED SETTING FOR SAFETY. SERIOUS OR

FATAL INJURY MAY RESULT.

To install the Kit, follow these procedures. The following

explanation assumes that the initial wiring was carried

out. Refer to Paragraph 3.7 which is a discussion of

tachometers, but may be generally applied here if differĆ

ences in wire entry and routing are kept in mind. For this

information refer to Figure 3 7.

Step 1 Ċ Orient the Module over the dedicated area

marked REFERENCE on the Regulator Module. just over

the 5 pins. (Refer to Figure 7.6.) Lower it so that the pins

pass through the guides on the Module. Use the screw

to secure it.

Step 2 Ċ Connect the external reference signal wires to

the terminal strip on the Module. Plus (+) on the left, miĆ

nus (-) on the right. Do not strip more than 1/8 inch (3

mm) of insulation off since shorts could occur at exposed

points. Maintain the twisted character as long as posĆ

sible.

Step 3 Ċ At this point refer to Paragraph 6.5.1 if the ReĆ

generative MinPak Plus is to follow a process instrument

controller signal. Refer to Paragraph 6.5.2 if the RegenĆ

erative MinPak Plus is to be set at a preset speed for conĆ

tinuous operation. The procedures differ.

6.5.1 Installing Instrument Interface Ċ When the Kit

is to be used as an instrument interface, follow these

Steps.

Step 1 Ċ Determine whether the maximum input signal

is between 0 to 5 mA or 5 to 50 mA. Locate the black pigĆ

tail jumper on the Module. (Refer to Figure 6.10.) CarefulĆ

ly place it on the directly corresponding pin, both of

which are clearly marked.

mA pins

Jumper J1

Figure 6.10 - Jumper J1, mA Pins

Step 2 Ċ This Step assumes that the complete drive sysĆ

tem, including the controller, has been successfully

started up and debugged according to Section 4 thru

Paragraph 4.4.1. It is now necessary to carry out a powerĆ

on test. Place the controller in the AUTO mode, if it is so

equipped. Set the process instrument controller for miniĆ

mum output. Locate the Auto Minimum Speed potenĆ

tiometer on the Interface Module Using a small insulated

screwdriver, adjust it for the desired minimum motor

speed. (CCW decreases speed.)

Step 3 Ċ Set the process instrument controller for maxiĆ

mum output. Locate the Auto Maximum Speed potenĆ

tiometer. Adjust it for the desired maximum motor speed.

(CW increases speed, CCW decreases it.)

Step 4 Ċ Since there is some interaction between these

two potentiometers, at times it may be necessary to work

back and forth to achieve precise adjustments.

6.5.2 Installing Preset Speed Ċ When the Kit is to be

used as a simple preset speed device follow these Steps.