Rockwell Automation MinPak Plus DC Drives Kits User Manual

Page 4

3

2.1.1 Local Station Ċ When the Station is mounted loĆ

cally on the Cover, users may select from five standard

Faceplates in order to configure a controller to a specific

drive application Refer to Table 6.B which is an inclusive

listing of Faceplate types, Model Numbers and functions.

Assuming the Cover is properly installed, the Faceplate

design maintains the NEMA Type 4/12 rating.

2.1.2 Remote Stations Ċ Some applications may reĆ

quire that the Operator's Control Station be remotely loĆ

cated. Briefly, the following three steps describe what

must be done:

D Select the blank Remote Operator Station Cover

Faceplate (Model 14C200).

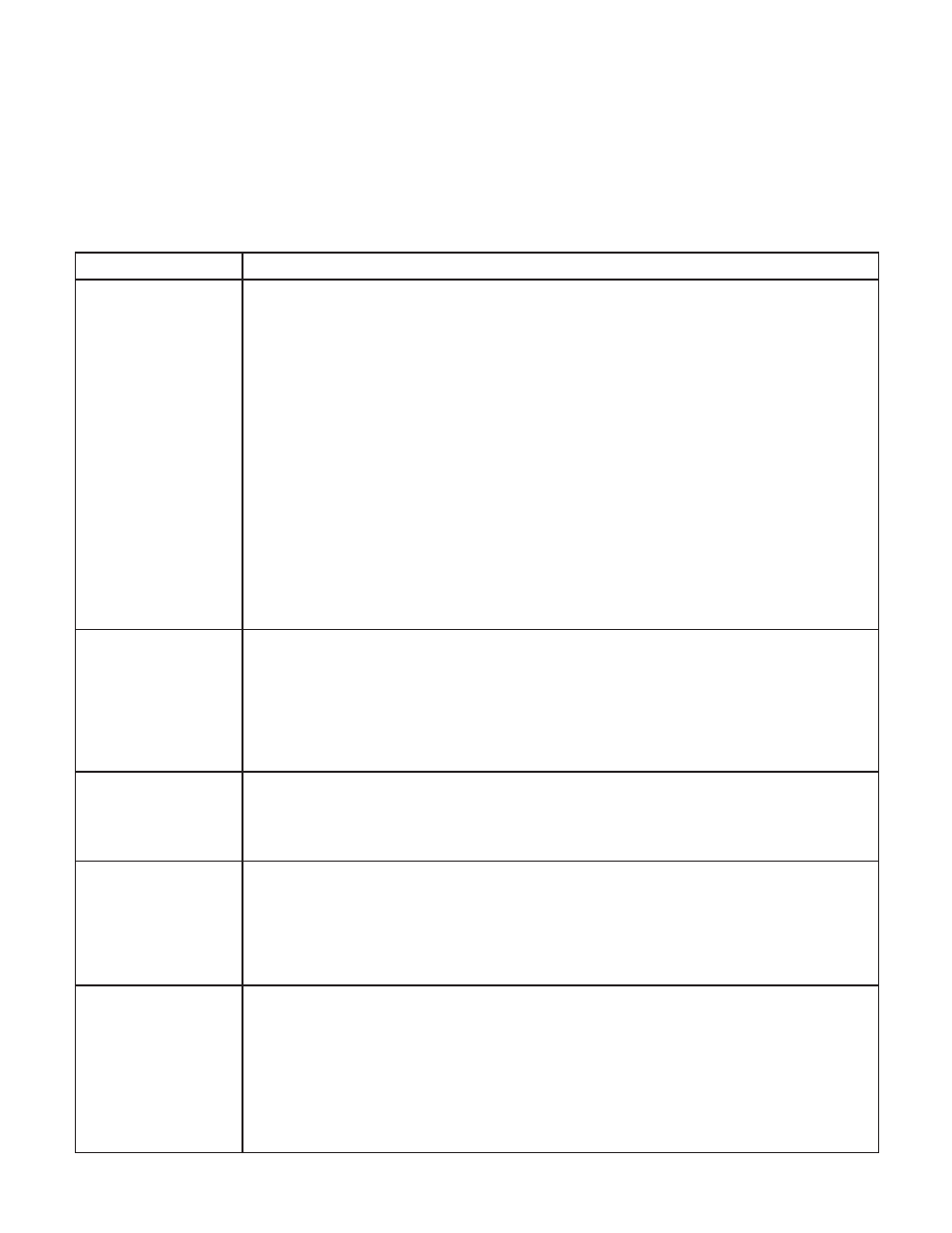

Table 2.A - REGENERATIVE MINPAK PLUS FEATURES SUMMARY

CATEGORY

FEATURE

Controller Functions

D START/STOP

D RUN/JOG

D FORWARD/REVERSE

D Speed selection (0Ć100%)

D Torque selection (10Ć150%)

D Full fourĆquadrant operation with coastĆtoĆrest on stop command standard. (Dynamic

braking available as option.)

D 20:1 controlledĆspeed range by means of armature voltage control.

D Armature loop contactor removes power to drive motor.

D Isolated armature voltage and current feedbacks decouples armature power from operator

devices and provides additional noise immunity.

D With tachometers specified in this manual, 0 5% or 1 0% speed regulation with a 95% load

change

D Operates and delivers rated output speed with specified regulation tolerance limits even

with aĆc line variations of "10% of nominal rated input voltage.

D Operates without component damage even with momentary aĆc line drops of -25% of

nominal input voltage.

Speed Regulation

D Jumper reconnectable regulator circuits which allow armature (A) or tachometer feedback

(T) regulation.

D With voltage regulation, 3Ć5% speed regulation with 95% load change.

D With tachometer specified, 1% speed regulation with a 95% load change. (Tachometers

are 5PY or REĆ020 dĆc tachometer.)

D With tachometer specified, 0.5% speed regulation with 95% load change. (Tachometer

is BC42.)

User Adjustments

D Separately adjustable forward and reverse current limits (10Ć150% of fullĆload current).

D Adjustable maximum speed (50Ć100% of base motor speed).

D Adjustable minimum speed (0Ć50% of base motor speed).

D Adjustable, separately set linear acceleration and deceleration rates (0.5Ć30 sec).

Safety

D Control circuitry guards against automatic restarting of equipment after resumption of

interrupted aĆc incoming power.

D Regulator and operator's controls isolated from aĆc line for personnel protection

D Armature voltage and current feedback isolated to assure separation of power and

regulator circuits.

D Motor thermostat protection (all horsepower ratings)

Hardware

D Conveniently located screw terminal connections for incoming aĆc and outgoing dĆc

power allow easy cable entry and connection

D Circuit breaker causes positive opening of aĆc line circuit in order to protect Power Cube

from armature short circuit

D Circuit breaker in armature circuit to prevent power module failure due to inverting fault.

D Protection from momentary surges on aĆc line and from dĆc load transients.

D DĆc motor contactor for positive motor disconnection.

D Contactor sequencing so that contactor closes and opens at zero armature current.