Rockwell Automation MinPak Plus DC Drives Kits User Manual

Page 3

2

Section 2

GENERAL CONTROLLER INFORMATION

2.0 General Ċ The Regenerative MinPak Plus DĆC VKS

drive controller may be applied to singleĆphase dĆc drive

applications with ratings within the following ranges:

D From 1/4 to 3/4 hp with a 115 VAC, 50/60 Hz input

voltage

D From 1/2 to 5 hp with 230 VAC, 50/60 Hz input

voltage

Reliance Electric dĆc motors, which may be used with the

controller, may be either permanent magnet motors up

to 1Ć1/2 hp or wound field (excited) motors up to 5 hp.

The controller provides powerĆconversion and control

circuits which convert the aĆc line voltage into adjustable

dĆc voltage in order to effectively control the drive motor.

The drive package consists of three basic drive compoĆ

nents:

D Regenerative MinPak Plus controller

D Operator's control station

D AdjustableĆspeed dĆc motor

Optional Modification Kits conveniently expand the caĆ

pability of the basic controller.

The Regenerative MinPak Plus controller is provided, as

standard, in a NEMA Type 4/12 enclosure intended for

wall or panel mounting. It is made up of a Chassis and

hinged Cover. (Type 4 may be generally defined as a

washdown" design. A specific definition is given at

Paragraph 2.5.) The enclosure may easily be converted

into a Chassis only type configuration for panel mounting

within a larger electrical enclosure. The optional Remote

Control Station may then be placed on the larger encloĆ

sure's face or some distance away.

A doubleĆpole POWER ON/OFF circuit breaker is stanĆ

dard with each Chassis and is independent of the Cover

and Faceplate. A singleĆpole circuit breaker in the armaĆ

ture circuit protects the controller and motor in the event

of an inverting fault.

The Regenerative MinPak Plus controller, in both NEMA

Type 4/12 or Chassis configurations, is Underwriters

Laboratories (U.L.) listed and Canadian Standards

Association (C.S.A.) certified.

The regenerative control unit contains two fullĆwave, fullĆ

control power conversion modules. These power modĆ

ules, along with their associated control circuitry, allow

selective current flow through the motor armature in eiĆ

ther direction under controlled conditions. The result is

an SCR drive that is able to provide positive or negative

torque output in either direction of motor rotation.

The controller's features are summarized in Table 2.A.

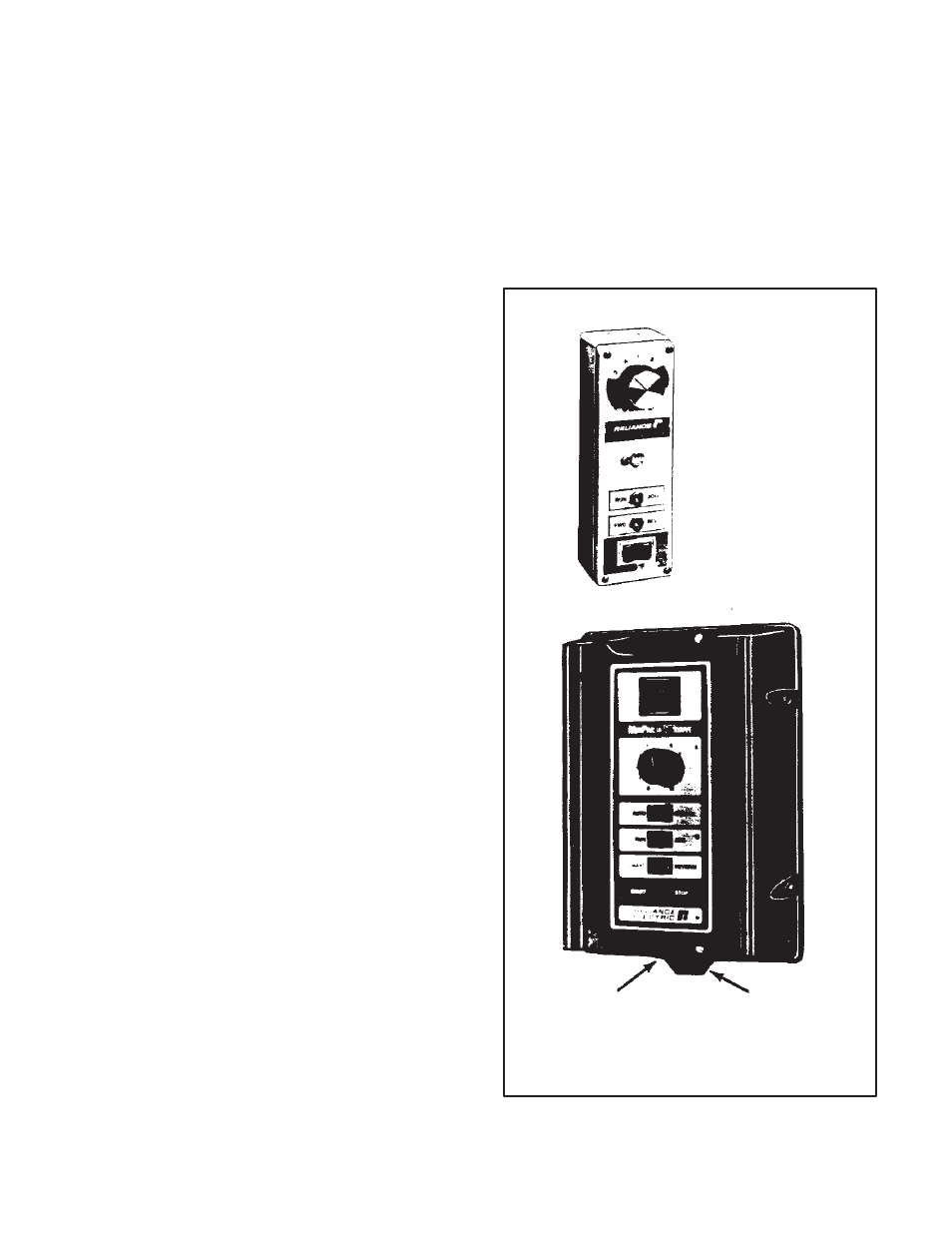

2.1 Operator's Control Station Ċ For proper operation

of the Regenerative MinPak Plus controller, it is necesĆ

sary to use an Operator's Control Station. (Refer to FigĆ

ure 2.1 .)The Operator Station allows the tailoring of conĆ

trol functions for the application. These may include:

D SPEED control potentiometer

D TORQUE control potentiometer

D AUTO/MANUAL selector switch

D RUN/JOG selector switch

D FORWARD/REVERSE selector switch

D START/STOP selector switch

There are two basic configurations that may be selected:

D Station mounted on controller Chassis Cover (local)

D Station mounted as a separate unit (remote)

Nameplate

Remote Operator

Control Station

Local Operator

Control Station

Security lock lip

Figure 2.1 - Remote and Local Operator Control

Stations