Rockwell Automation MinPak Plus DC Drives Kits User Manual

Page 27

26

In cases where the Kit is secured by a mounting screw,

be sure to tighten it firmly but do not overtighten. ExcesĆ

sive force can strip the threads in the cast base.

6.1 Local Operator Faceplates Ċ When a Local OperĆ

ator Station is used with the Chassis Cover, one of five difĆ

ferent Chassis Faceplates must also be used. Each

Faceplate supports a number of selector switches and

potentiometers, as required by the specific application.

(Refer to Figure 6.2 and to Table 6.B for a list of FaceĆ

plates and related switches.)

The Faceplates are supplied with a bag of eight hex keps

nuts. The standard hex nut is used to secure the ground

wire. No other equipment nor any other Reliance Electric

options are required with this option.

NOTE: In cases where the Chassis is mounted without a

Cover. there is no need for a Faceplate. In this case, igĆ

nore these instructions.

It a Local Operator Station contains a AUTO/MANUAL

switch, it is necessary to remove jumper J4 from the RegĆ

ulator Module. (Refer to Figure 7.6.)

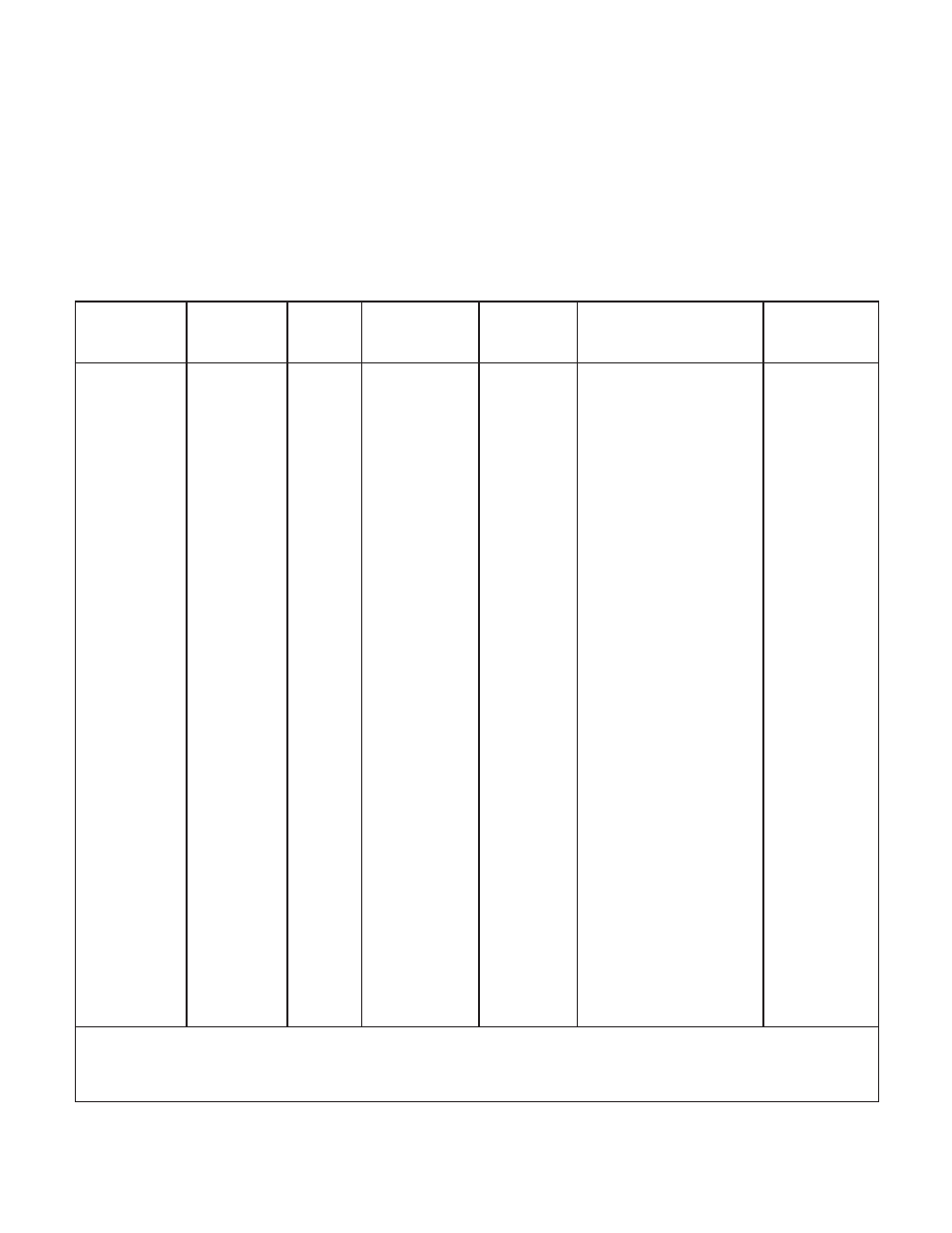

Table 6.A - MODIFICATION KIT QUICK REFERENCE LIST

KIT

MANUAL

PARAGRAPH

NUMBER

MODEL

NO.

CONTROLLER

MODIFICATION

?➀

ADDITIONAL

OPTIONS

REQUIRED

?

OPTIONS

REQUIRED

ADDITIONAL

USERĆ

SUPPLIED

PARTS?

Local Operator

Station

Faceplates

Blank Operator

Station

Faceplate

Remote

Operator

Adapter Kit

Auxiliary

M Contact

Voltage

Tachometer

Follower

Test Meter

Adapter

Field Supply ➂

Dynamic

Braking

Instrument

Interface/

Preset Speed

Master Isolated

Reference

Receiver

Dancer

Follower

6.1

6.2

6.2

6.7

6.4

6.8

6.6

6.3

6.5

6.9

6.10

14C202

14C204

14C206

14C208

14C200

14C220

14C219

14C223

14C225

14C228

14C214

thru 16

14C222

14C229

14C230

no

no

yes

no

yes

no

no

no

yes

yes

yes

no

yes

yes

no

no/yes

no

no

no

no/yes

no/yes

yes

no

None

D Reliance Remote

Operator Control Station

(Refer to Table 2.B.)

D Remote Operator

Adapter

(See Blank Faceplate, just

above.)

None

May need AUTO/MANUAL

selector switch

None

None

D If preset speed only, may

need AUTO/MANUAL

switch.

D If follows process

controller, May need

AUTO/MANUAL switch.

Master Isolated Reference

Transmitter

None

no

wire ➁

wire ➁

wire ➁ ➃

wire ➁

no

wire ➄

no

no

wire ➁

wire ➁

wire ➁

Dancer Pot and

optional Dancer

Position Pot

➀

Modification here means that some work such as jumper placement, resistor clipping, or wiring reconnection must be performed.

➁

Refer to Table 6.C.

➂

Supplied as standard with 2, 3 and 5 hp Regenerative MinPak Plus controllers.

➃

Not to exceed AWG No. 14.

➄

Refer to Paragraph 6.6 for specific sizes.