Rockwell Automation MinPak Plus DC Drives Kits User Manual

Page 34

33

41

42

COM

43

COM

41

42

43

NC

NO

Figure 6.14 - External Wiring, Auxiliary M

Users supply the wiring to external devices. Size is deĆ

pendent on the specific application. It should not exceed

AWG No. 14.

The maximum rating of each contact is 1 ampere at 30

VDC (resistive) or 0.5 ampere at 120 VAC (resistive).

Under no circumstances should these contacts be used

to control brakes or other power loads.

To install the Kit, follow these procedures.

Step 1 Ċ Mount the Auxiliary M Contact Module on the

center of the Auxiliary Mounting Bracket. Note that

orientation is important. The overhanging edge of the asĆ

sembly must hang over the Regulator Module. Then

snap the assembly into the Bracket.

Step 2 Ċ Connect the threeĆwire harness to the RegulaĆ

tor Module. Locate the letters AUX M printed on the ModĆ

ule near a threeĆpin connector. (Refer to Figure 7.6.) The

connector fits on the bayonet pins. Note that the yellow

wire must connect with the pin marked YEL 38 on the

Regulator Module.

Step 3 Ċ Draw external wiring into the Chassis. Follow

Figure 3.7 for conduit access and routing.

Step 4 Ċ Route external wiring to the Module's terminal

block. Do not strip more than 1/4 inch (6 mm) of insulaĆ

tion from the wires since shorts could occur at exposed

points.

6.8 Test Meter Adapter Ċ Measuring and monitoring of

Regenerative MinPak Plus regulator voltages can be

safely and conveniently carried out with the optional Test

Meter Adapter Kit. (Refer to Figure 6.15.) It acts as an inĆ

terface between the Regulator Module and a user's voltĆ

meter.

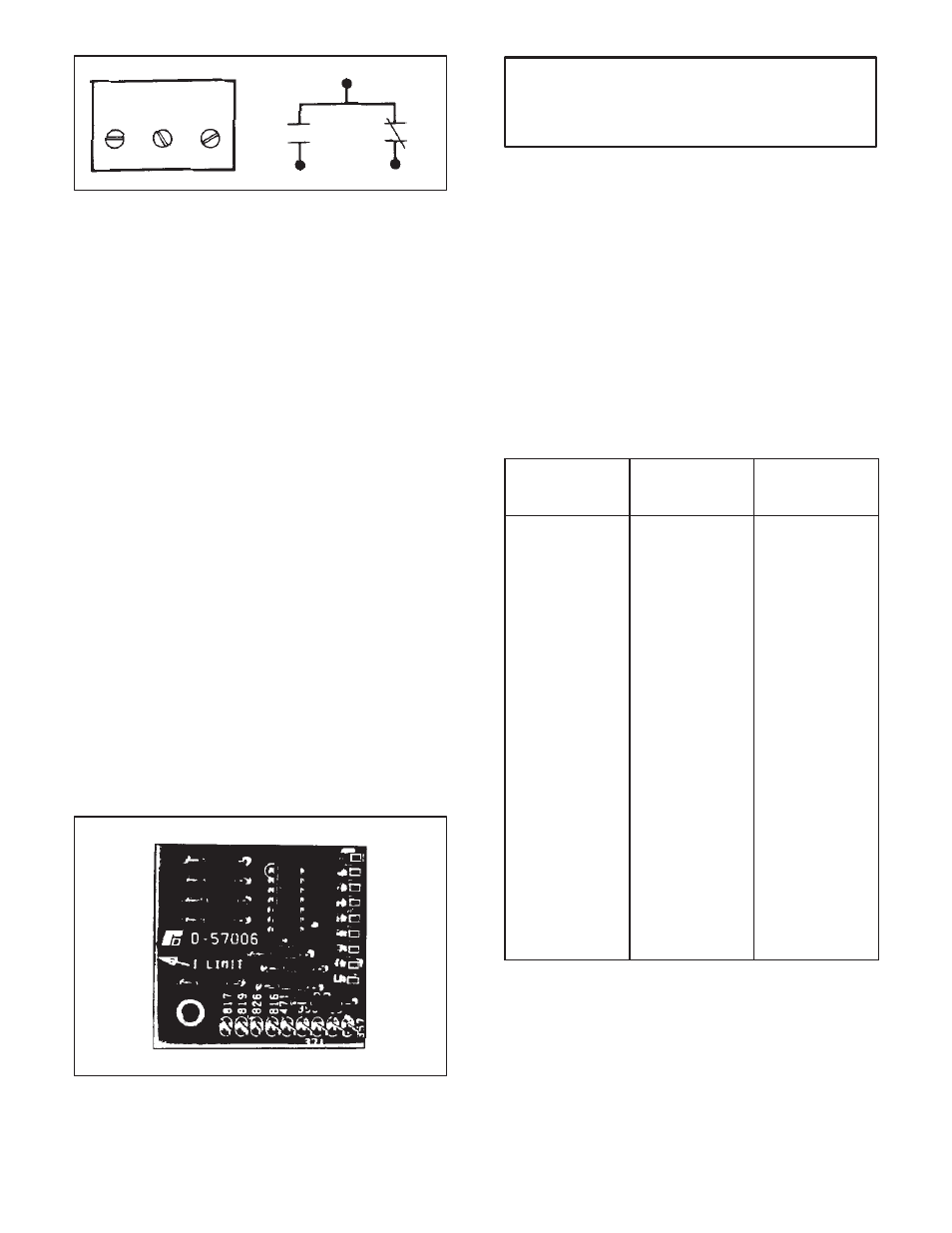

Figure 6.15 - Test Meter

CAUTION: Under no circumstances should the

probes of a meter be connected directly to the pins

on the Regulator Module. Permanent damage to

the solid state components can occur.

The Kit contains a Module and a mounting screw. Except

for the voltmeter, no other equipment is necessary. The

meter should be a multimeter having a sensitivity of

20,000 ohms per volt minimum. (Simpson Model 260,

Triplett Model 630, or equivalents are acceptable.)

To install and use the Kit, follow these procedures.

Step 1 Ċ Orient the Adapter Module over the area on the

Regulator Module marked TEST, just over the 9 pins. (ReĆ

fer to Figure 7.6.) Lower it so that the pins pass through

the guides on the Module. Use the screw to secure it.

Step 2 Ċ For use, refer to Table 6.D where the function

is shown in relation to the test terminals to be used. The

normal operating voltages are also shown.

Table 6.D - TEST ADAPTER TERMINALS, READINGS

FOR FUNCTION

USE

TERMINALS:

NORMAL

INDICATION

(VDC):

Unregulated

+20 VDC

Power Supply

Unregulated

*20 VDC

Power Supply

Regulated

+11.2 VDC

Power Supply

Regulated

*11.2 VDC

Power Supply

LVTU (linear

voltage time unit)

Input

Major Loop

Feedback

Forward/Reverse

Driver Outputs

+456

*357

*471

+357

+356

*357

*371

+357

+826

*357

*819

+357

*816, *817

+356

16-28

16-28

10.8-11.5

10.8-11.5

0-8.0

0-4.0

On 10 VDC scale,

increase of

approx. 1 VDC

occurs when

drive is started.

6.9 Master Isolated Reference Receiver Ċ The addiĆ

tion of the optional Master Isolated Reference Receiver

Kit allows the Regenerative MinPak Plus to receive and

decode a PWM speed reference signal from the Master

Isolated Reference Transmitter. The Receiver Kit consists

of two printed circuit boards: a Switch Receiver Module

and a Reference Receiver Module which are mounted on

the Regenerative MinPak Plus Regulator Module. (Refer

to Figure 6.16.)