Rockwell Automation MinPak Plus DC Drives Kits User Manual

Page 36

35

Step 5 Ċ Using a twisted pair, connect the external refĆ

erence wires (wires 1 and 2) from the external Master

Isolated Reference Transmitter to the terminal block on

the Reference Receiver Module in the controller cabiĆ

net. Connect wire 1 to terminal 1 and wire 2 to termiĆ

nal 2.

NOTE: Do not strip more than 1/8 inch (3 mm) of insulaĆ

tion off the ends of the wires because a short circuit

could occur at any point where the bare wire is exposed.

Maintain the twisted configuration of the two wires as

much as possible.

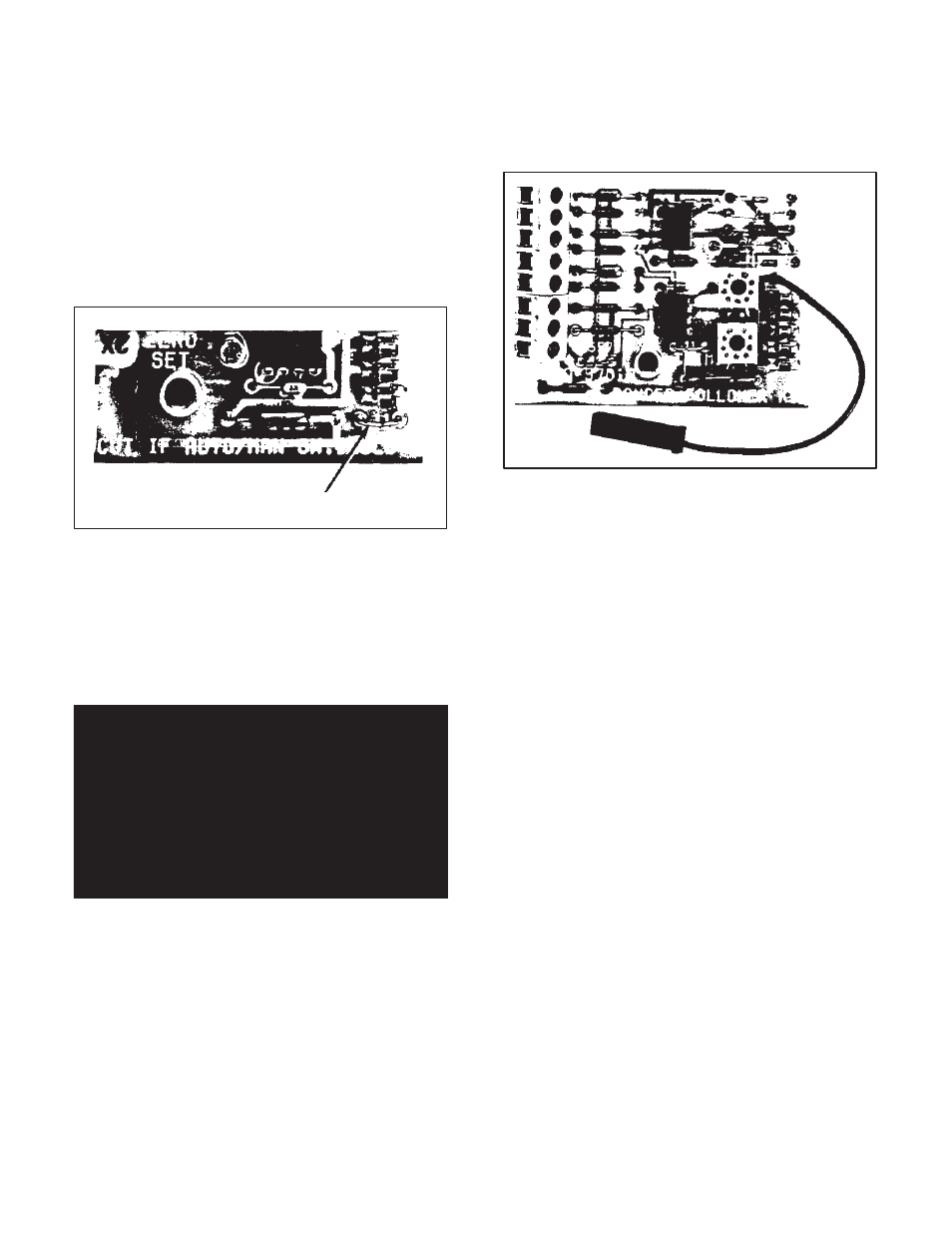

Step 6 Ċ If an AUTO/MANUAL selector switch is inĆ

cluded in the Operator Control Station, cut jumper J1 on

the Reference Receiver Module. (Refer to Figure 6.18.)

Jumper J1

Figure 6.18 - Jumper J1 on Reference

Receiver Module

Step 7 Ċ With the MASTER Speed potentiometer on the

Master Isolated Reference Transmitter set at zero, deĆ

press the START pushbutton on the Master Isolated RefĆ

erence Transmitter. Adjust the ZEROSET potentiometer

on the Reference Receiver Module to obtain zero speed

of the drive motor.

DANGER

ALTHOUGH ZERO SET ADJUSTMENT ON THIS

KIT ALLOWS FOR ADJUSTMENT DOWN TO

ZERO SPEED, THIS ZERO SPEED SETTING

MUST NOT BE USED WHERE THE OPERATOR

MAY RELY ON A MAINTAINED ZERO SPEED.

ELECTRICAL NOISE, IMPROPER WIRING,

POWER LINE, OR MALFUNCTIONING COMĆ

PONENTS MAY CAUSE THE DRIVE TO TURN

ON WHILE AT THE ZERO SPEED SETTING.

6.10 Dancer Follower Ċ The Dancer Follower Kit allows

the Regenerative MinPak Plus to be controlled automatiĆ

cally in response to a speed reference generated by a

line speed signal and trimmed by a Dancer potentiomeĆ

ter. Applications include web process lines where a drive

must closely follow or maintain the position of a dancer.

The Kit contains the Dancer Follower Module and a

mounting screw. Although the Regenerative MinPak Plus

can use the Kit for exclusive automatic speed control, if

manual override control is needed, an AUTO/MANUAL

selector switch must be used on the Local or Remote OpĆ

erator Control Station. (Refer to Table 2.B.) In the MANUĆ

AL position, the drive responds to the SPEED potentiomĆ

eter setting. In AUTO, it follows only the external signals

and does not respond to manually input speed change

commands. (Refer to Figure 6.19.)

Figure 6.19 - Dancer Follower Module

The Kit is designed to accept a line speed input signal of

4 to 10 VDC to obtain maximum speed. The input impedĆ

ance between the line speed input terminals 57 and 726

is approximately 25,000 ohms. The Dancer potentiomeĆ

ter will provide up to a 20% trim to the line speed signal.

The user must supply the required lengths of the speciĆ

fied signal wire. (Refer to Table 6.C.) A Dancer potentiomĆ

eter and an optional Dancer Position potentiometer are

also to be supplied by the user.

To install the Kit, follow these procedures.

Step 1 Ċ Refer to Figure 7.6 and note the heavy border

area in the center of the Regulator Module marked REFĆ

ERENCE. This is the area where the Dancer Follower

Module is to be mounted. Place the Dancer Follower

Module in the proper orientation so the pin guides on the

Module are aligned over the set of five pins on the ReguĆ

lator Module. Lower the Dancer Follower Module so the

pins pass through the pin guides and the mounting

spacer seats in the mounting hole. (It may be necessary

to remove a protective plastic cap from the pins.) Secure

the Module with the supplied screw.

Step 2 Ċ Connect the black pigĆtail jumper of the Dancer

Follower Module to pin 319 on the Regulator Module.

(Pin 319 is the top pin of a group of two pins along the

right hand edge.)

Step 3 Ċ Using a twisted pair, connect the external line

speed input to the terminal strip of the Dancer Follower

Module. The plus (+) wire is connected to terminal 726

and the minus (-) wire is connected to terminal 57.

NOTE: Do not strip more than 1/8 inch (3 mm) of insulaĆ

tion off the ends of the wires because a short circuit could

occur at any point where the bare wire is exposed. MainĆ

tain the twisted configuration of the two wires as much as

possible.