Rockwell Automation MinPak Plus DC Drives Kits User Manual

Page 15

14

Take these two figures and relate them to Table 3.B. Read

across to the right column, where the 100% voltage figĆ

ure is indicated. Place the jumper on the Module's pin

that corresponds to this figure.

Table 3.B - TACHOMETERVOLTAGE SCALING

MOTORBASE

SPEED

(rpm)

TACHOMETER

(volts/1000 rpm)

100%

VOLTAGE

CONNECTION

1150

1750

1150

3450

1750

1150

3450

1750

ă20 VDC

ă20 VDC

ă50 VDC

ă20 VDC

ă50 VDC

100 VDC

ă50 VDC

100 VDC

23

35

58

69

88

115

175

175

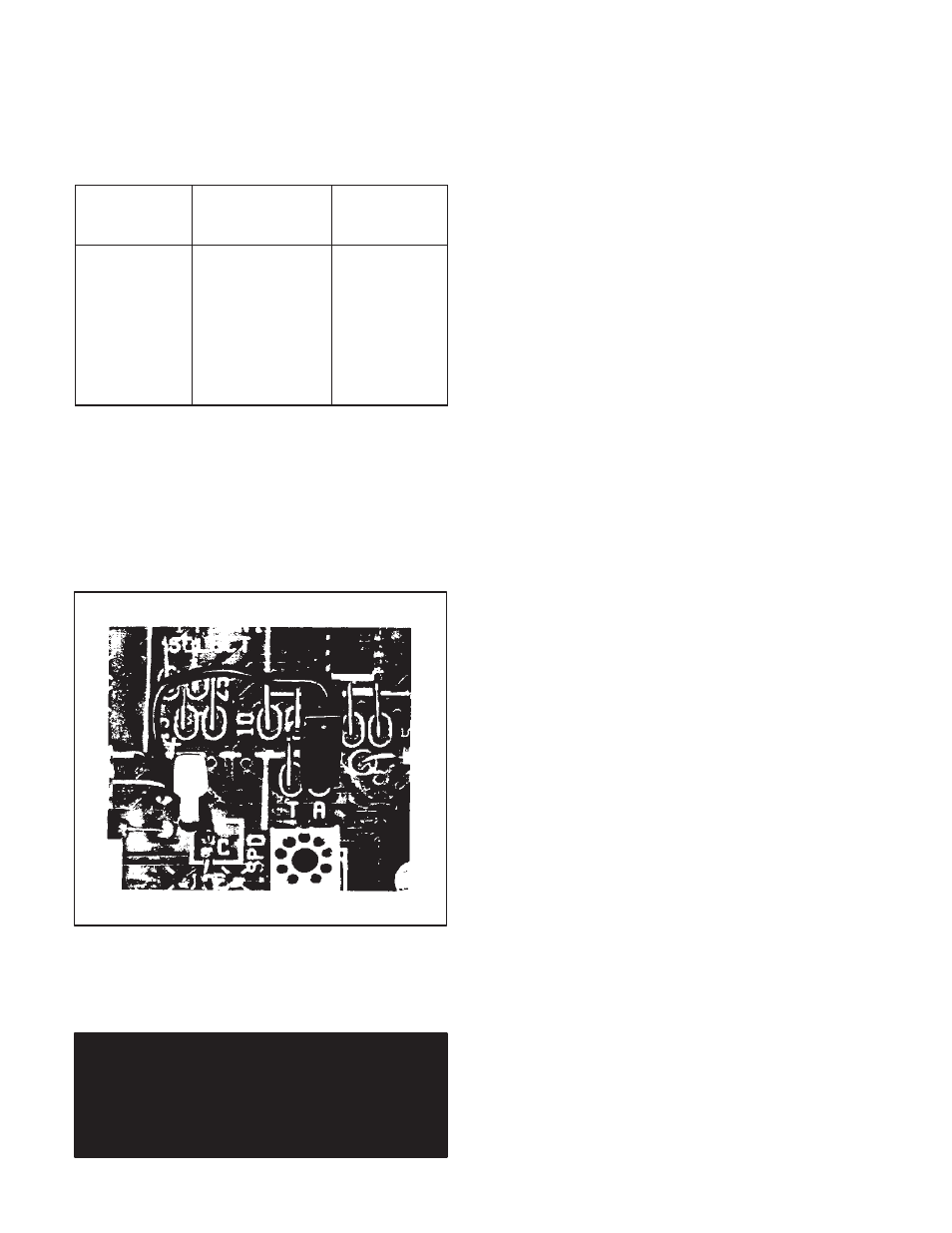

Step 3 Ċ The Feedback Jumper on the Regulator ModĆ

ule must be connected for tachometer feedback. (Refer

to Figure 3.9.) Place the Regulator Module's fixed black

jumper on the pin marked T.

Figure 3.9 - Feedback Connection on Regulator

Module

DANGER

IMPROPER TACHOMETER CONNECTION WITH

RESPECT TO POLARITY WILL RESULT IN UNĆ

CONTROLLED MOTOR SHAFT ACCELERATION

WHICH MAY RESULT IN SEVERE PERSONAL INĆ

JURY AND/OR EQUIPMENT DAMAGE.

NOTE: A recommended way to check the polarity of the

tachometer is to run the controller as a Voltage RegulaĆ

tor while observing the tachometer output with a dĆc voltĆ

meter.

Step 4 Ċ This Step assumes that the complete drive sysĆ

tem, including the controller, has been successfully

started up and debugged according to Section 4 thru

Paragraph 4.4.1. It is necessary to carry out a powerĆon

test. Set the SPEED potentiometer at approximately 25%

of full rotation. Start the drive. It should run as set. If it acĆ

celerates to full speed, the tachometer is not providing a

signal or is improperly connected.

Stop the drive, turn off all power, and check and correct

the leads to the Tachometer Module's terminal strip. ReĆ

peat the test with power on in order to confirm that proper

feedback signals are being received by the regulator.

If erratic behavior continues, check the placement of the

two pigĆtail jumpers against Steps 2 and 3.

Step 5 Ċ The Maximum and Minimum Speed PotenĆ

tiometers should now be adjusted to Paragraphs 4.4.2

and 4.4.3. Be sure to follow 4.4.4, and 4.4.5.

After wiring, examine connections at both ends to make

sure wire connections were correctly made. Confirm wire

identification. Examine the firmness of connections.

3.8 Operator Station Wiring Ċ Both the local Operator

Control Faceplate and the Remote Operator Control StaĆ

tion are purchased as options. Thus, they are discussed

in Section 6. Modification Kits.

3.8.1 Local Faceplate Ċ If the Regenerative MinPak

Plus controller is to be used for local'' operator control,

it is necessary to mount one of five optional Faceplates

in the cutout on the Chassis Cover. (''Local" is defined as

having all control switches and potentiometers on the

controller's Cover.)

A local configuration requires no external wiring through

conduits. Complete procedures are listed at Paragraph

6.1.

3.8.2 Remote Station Ċ If the Regenerative MinPak

Plus controller is to be used for remote" operator conĆ

trol, it is necessary to mount an optional blank Faceplate

in the cutout on the Chassis Cover. Also, an optional ReĆ

liance Electric Remote Operator Control Station must be

wired to the Remote Operator Station Kit mounted in the

controller. ("Remote" is defined as not having any control

switches mounted on the Chassis Faceplate.)

A remote configuration requires userĆsupplied external

wiring between the Station and the controller. These

wires must run through a dedicated conduit and enter

the controller through an assigned conduit well. (Refer to

Figure 3.7.)

3.9 50ĆHz Operation Ċ There may be cases when the

Regenerative MinPak Plus controller is to be operated

continuously on 50 Hz. If so, two resistors should be reĆ

moved from the Regulator Module for optimum perforĆ

mance. (Refer to Figure 3.10.)

3.10 Isolation Transformers Ċ Although an autoĆtransĆ

former may be required because of aĆc line voltage levĆ

els, it is unable to provide a number of benefits standard

with an isolation transformer. (Refer to Guideline 16.)

Note also Guideline 15 concerning the position of the aĆc

line disconnect switch in relation to the transformer.