Rockwell Automation MinPak Plus DC Drives Kits User Manual

Page 35

34

The Operator Control Station AUTO/MANUAL selector

switch is used to obtain local control or master reference

control of the individual drive. When the selector switch

is placed in the AUTO mode, the individual drive SPEED

potentiometer automatically is converted into a draw pot

adjustment for precise trim control between drives. The

only adjustment requirement is a zero set adjustment on

the Reference Receiver Module. Should the speed referĆ

ence wires become disconnected, the Regenerative

MinPak Plus will go to zero speed.

Master Isolated Reference controlled Regenerative MinĆ

Pak Plus's are ideally suited for multiple conveyor drives,

proportional pumps, feeder drives, web lines or other

similar operations which require multiple drives to follow

a common reference signal and provide hold back

torque.

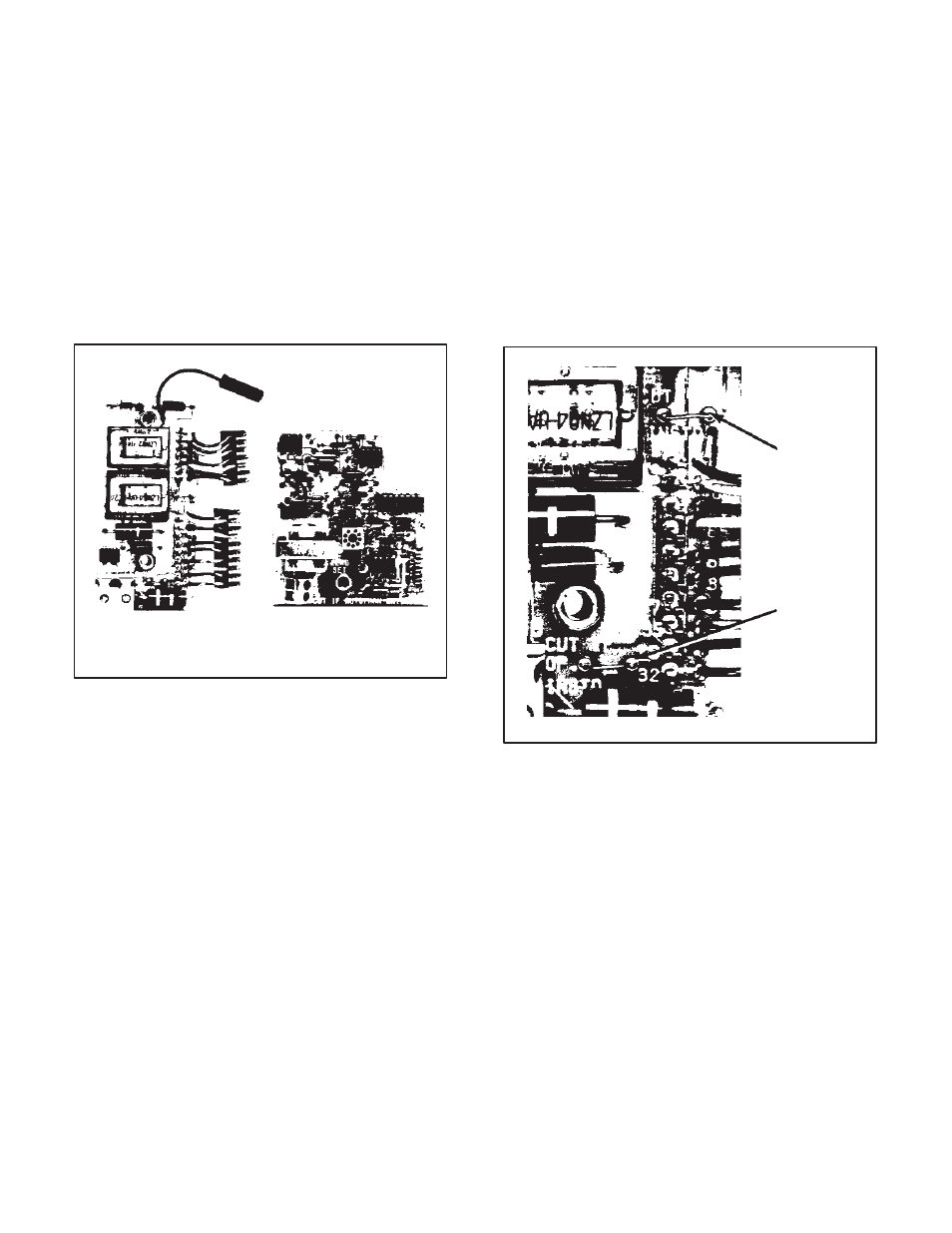

Switch Receiver

Module

Reference Receiver

Module

Figure 6.16 - Master Isolated Reference

Receiver Kit

To install the Kit, follow these procedures:

Step 1 Ċ Refer to Figure 7.6 and note the heavy border

area at the extreme leftĆhand side of the Regulator ModĆ

ule. This is the area where the Switch Receiver Module

is to be mounted. Place the Switch Receiver Module in

the proper orientation so the two connectors are aligned

over the two sets of pins (marked GRN 28 and RED 32).

Carefully, slowly and gently press the connectors down

on the pins until they bottom. Then, connect the black

pigĆtail jumper of the Switch Receiver Module to pin 40

on the Regulator Module.

Step 2 Ċ Fold the PC board over the top of the two conĆ

nectors so the mounting spacers fit into the mounting

holes.

If a Local Operator Station is being used, secure the

Switch Receiver Module with the two short screws proĆ

vided. The Local Operator Station is then mounted and

connected to the two sets of pins on the Switch Receiver

Module as described in paragraph 6.1.

If a Remote Operator Station is being used, mount the

Remote Operator Adapter Module on top of the Switch

Receiver Module and secure the two PC boards with the

two long screws provided with the kit as described in

Paragraph 6.2. See Figure 7.4 for proper connections to

the Switch Receiver Module and Remote Operator

Adapter Module. Refer to notes 35 and 36 in Figure 7.4.

NOTE: The external startĆstop wires from the Master IsoĆ

lated Reference Transmitter (wires 189 and 288) must be

connected to the Switch Receiver Module (Refer to Step

4.) before mounting the Remote Operator Adapter ModĆ

ule on the Switch Receiver Module. Jumpers J1 and J2

on the Switch Receiver Module (Refer to Figure 6.17.)

must be cut when Local or Remote Operator Stations are

used. These jumpers are left connected when only conĆ

trol from the Master Isolated Reference Transmitter is deĆ

sired.

Jumper J2

Jumper J1

Figure 6.17 - Jumpers J1 and J2 on Switch

Receiver Module

Step 3 Ċ Refer to Figure 7.6 and note the heavy border

area in the center of the Regulator Module marked REFĆ

ERENCE. This is the area where the Reference Receiver

Module is to be mounted. Place the Reference Receiver

Module in the proper orientation so the pin guides on the

Module are aligned over the set of five pins on the ReguĆ

lator Module. Lower the Reference Receiver Module so

the pins pass through the pin guides and the mounting

spacer seats in the mounting hole. (It may be necessary

to remove a protective plastic cap from the pins.) Secure

the Module with the supplied screw.

Step 4 Ċ Connect the external startĆstop wires (wires

189 and 288) from the external Master Isolated ReferĆ

ence Transmitter to the terminal block on the Switch ReĆ

ceiver Module in the controller cabinet.

NOTE: If remote operator devices are used, this step

must be completed before installing the Remote OperaĆ

tor Adapter Module (Step 1).