Rockwell Automation MinPak Plus DC Drives Kits User Manual

Page 13

12

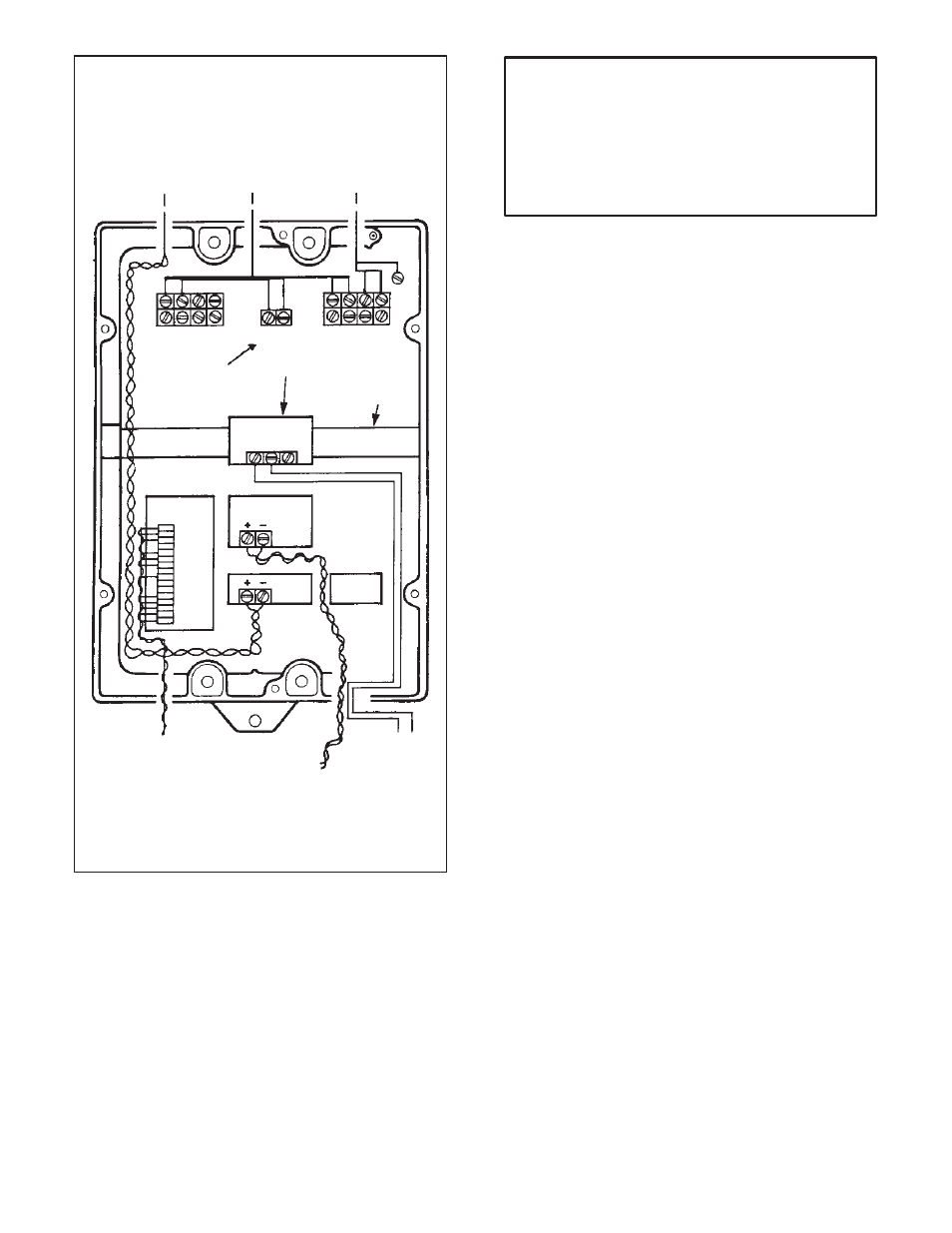

1/2"-14 thread

3/4"-14 thread

3/4"-14 thread

1/2"-14 thread

1/2"-14 thread

Remote Operator

Station

input wires

Input

for

Process Control

or

Auto Reference

Output

from

Auxiliary

M

Conductor

Tach

Feedback

Auxiliary

Bracket

Auxiliary M

Module

Field wiring

only if Kit

used.

Tach

input

wires

DĆc

output

conductors

AĆc

output

conductors

Figure 3.7 - Chassis Wells, Wire Routing

3.5.2 DĆC Wiring Ċ The next wires to be drawn into the

controller's Chassis are the dĆc armature control conducĆ

tors. If the optional Field Supply Kit is being used, the

field wiring conductors will also be drawn in. The motor

thermostat conductors are to be drawn in, too. All use the

same conduit.

Make sure that Guideline 10 has been considered. Wire

according to Figure 3.8.

WARNING

DO NOT ALLOWCONDUCTORS TO GROUND

ON THE CHASSIS OR CONDUITS. CHECK INĆ

TEGRITY OF ALL WIRE INSULATION BEFORE

DRAWING. REMOVE ONLY ENOUGH INSULAĆ

TION TO MAKE A FIRM TERMINAL CONNECĆ

TION. PERSONAL INJURY COULD RESULT IF A

BARE WIRE TOUCHES THE CHASSIS.

Field Supply wiring should also be performed now. It is

standard on 2, 3 and 5 hp controllers and optional on

lower ratings. A Field Supply Kit must be installed in the

controller to accept this wiring.

Motors with dualĆvoltage shunt fields should be conĆ

nected for the higher voltage. Connect:

D 90Ćvolt armature/100Ćvolt field

D 180Ćvolt armature/200Ćvolt field

D For half wave connections, refer to Figure 6.12

After wiring, examine all connections to determine that

they are correctly made at both ends. Confirm wire idenĆ

tification. Examine the firmness of the connections.

3.6 Thermal Overload Wiring Ċ The controller is

shipped without a jumper between terminals 32 and 132.

The motor thermostat or an external overload must be

connected to these terminals to meet local code requireĆ

ments.

NOTE: An external overload device must be connected

between terminals 32 and 132. The drive will not start

without it.

3.7 Tachometer Feedback Ċ The Regenerative MinĆ

Pak Plus controller may be connected to a dĆc tachomeĆ

ter. An aĆc tachometer cannot be used.

Not all drives require the use of a tachometer. This ParaĆ

graph should be read and followed only if the specific

system requires one. If your drive system does not use

a tachometer, proceed to Paragraph 3.8.

The following procedures assume that Guideline 10 has

been considered. These procedures are limited to preĆ

paring the incoming signal wires and wiring them at

the tachometer.

Note that a twisted pair signal wire must be used for the

tachometer feedback circuit. It is specified in Table 6.C.

The cable run between the motor and the controller must

be through a dedicated conduit. Under no circumĆ

stances attempt to use the aĆc or dĆc conduits.

Wire according to Figure 3.8 and the following proceĆ

dure.

Step 1 Ċ Connect the tachometer wires to the terminal

strip on the Module Plus (+) is the left side, minus (-) the

right. Do not strip off more than 1/8 inch (3 mm) of insulaĆ

tion since shorts occur at exposed points. Maintain the

twist as long as possible.

Step 2 Ċ Locate the black pigĆtail jumper on the

Tachometer Module. It is to be placed on one of eight

pins on the Module. Exactly which depends on the voltĆ

age scaling factor. On the motor's nameplate, find the

base speed (rpm). On the tachometer's nameplate,find

the output voltage per 1000 rpm.