Rockwell Automation MinPak Plus DC Drives Kits User Manual

Page 30

29

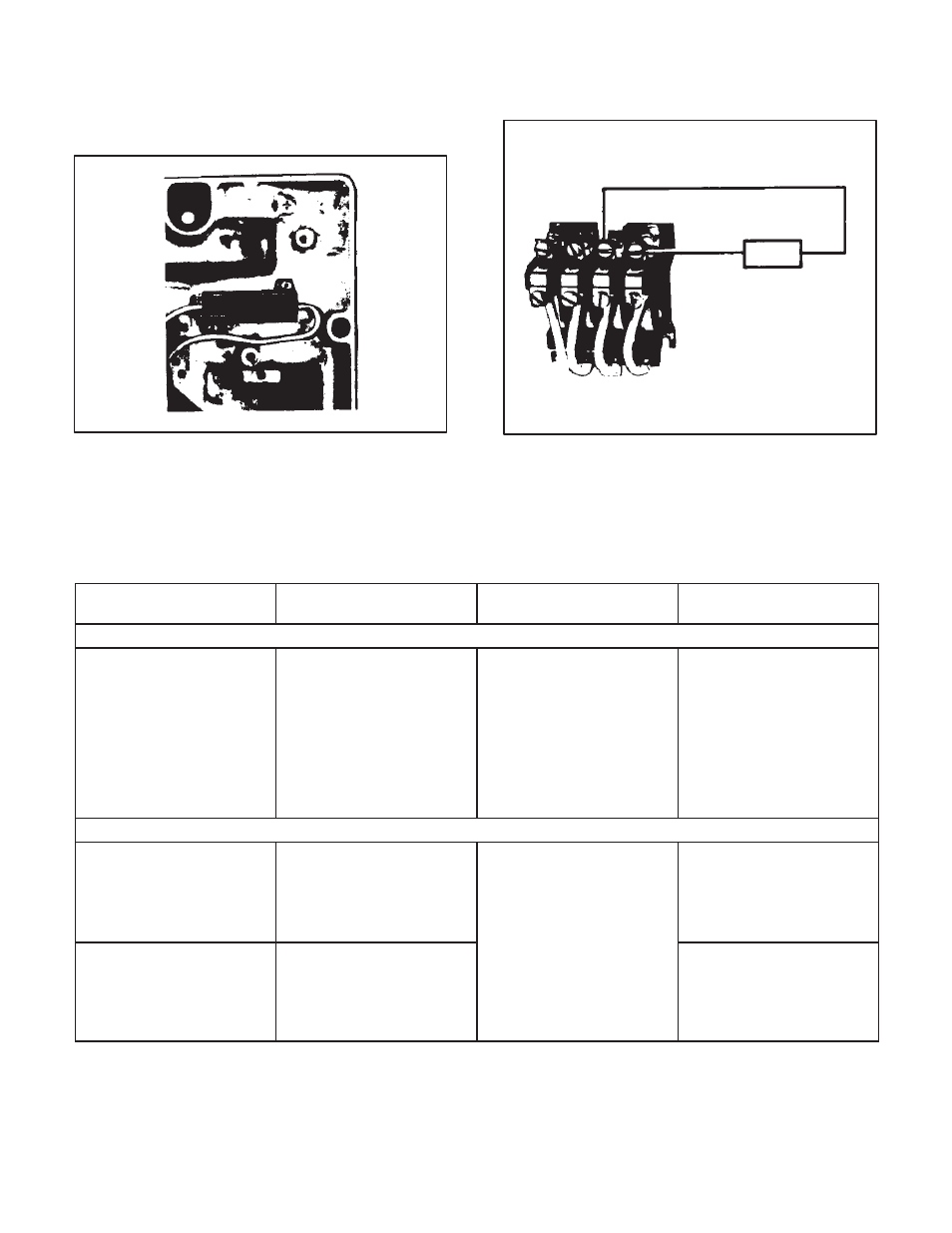

Step 4 Ċ Locate the area of the Chassis where the DyĆ

namic Braking resistor is to be placed. (Refer to Figure

6.5 ) Using the two screws included in the Kit, mount the

resistor onto the Chassis. Place the longer lead pointing

to he nearer Chassis edge.

Figure 6.5 - D.B. Resistor in Chassis

Step 5 Ċ It is necessary to connect both leads to the M

Contactor. Figure 6.6 shows the contactor and the elecĆ

trical connections for the Dynamic Braking resistor.

longer wire

first''

row

M contactor

D.B.

Figure 6.6 - Connecting Dynamic Brake

Table 6.C - WIRE SPECIFICATIONS

USE IN CONTROLLER

TYPE CONDUCTOR

REQUIRED

CHARACTERISTICS

ACCEPTABLE TYPES

CONTROL WIRES

Remote Operator

Control Station:

D AUTO/MANUAL

D JOG/RUN

D FORWARD/REVERSE

D START/STOP

D Single conductor and/or

multiĆconductor

D Stranded copper

D AWG No. 16

D 600 VAC rating

D Insulation: polyĆvinyl

chloride (PVC)

D Temperature range:

40

°

-105

°

C (104

°

-221

°

F)

D Unshielded

D Any single conductor

meeting N.E.C. required

characteristics

SIGNAL WIRE

Remote Operator

Control Station:

D SPEED pot

D TORQUE pot

D ThreeĆconductor

D Twisted with two twists per

inch

D Stranded copper

(19 29)

D AWG No. 16

D 600 VAC rating

D Twist per foot:

D User may twist single

conductors of required

specifications

D Reliance Part No.

417900-79X

D Tachometer Feedback

D Instrument Interface

D Voltage/Tachometer

Follower

D TwoĆconductor

D Twisted pair with two twists

per inch

D Twist per foot:

24 (1/2-inch lay)

D Insulation: polyĆvinyl

chloride (PVC)

D Temperature range:

40

°

-105

°

C (104

°

-221

°

F)

D User may twist single

conductors of required

specifications

D Reliance Part No.

417900-76EAD