Rockwell Automation MinPak Plus DC Drives Kits User Manual

Page 21

20

Step 5 Ċ When the voltage across F1 and F2 is at the

proper level, put the POWER ON/OFF circuit breaker in

the OFF position and close the Chassis Cover.

4.3.3 Drive Motor Check Ċ It is necessary to determine

if the drive motor is rotating in the direction required by

the application. (Note that the motor is not connected to

the load at this time if all steps to this point have been folĆ

lowed.)

Step 1 Ċ Apply the main aĆc line power by closing the

disconnect.

Step 2 Ċ On the Regenerative MinPak Plus controller,

place the SPEED potentiometer at a setting between 1

and 4.

Step 3 Ċ Place the FORWARD/REVERSE selector

switch in the FORWARD position.

Step 4 Ċ Place the RUN/JOG selector in the JOG posiĆ

tion.

Step 5 Ċ If the Operator Station has an AUTO/MANUAL

selector switch, place it in the MANUAL position.

Step 6 Ċ Push and hold in the START/STOP rocker

switch to the START position. The drive should accelerĆ

ate to the speed set on the potentiometer. Release the

switch, and the drive will stop.

CAUTION: If the drive motor does not begin turning

at this time, press the STOP rocker switch immediĆ

ately. Put the POWER ON/OFF circuit breaker in the

OFF position. Open the main aĆc line disconnect.

Begin an organized troubleshooting procedure to

determine why the motor does not operate. Do not

leave power on.

Step 7 Ċ If the drive works properly in the JOG mode,

place the control in the RUN mode and repeat Steps 4

thru 6.

Step 8 Ċ Observe the direction of rotation of the shaft.

If it turns in the desired direction, proceed to Paragraph

4.3.4. If the motor is turning in the opposite direction,

continue with these Steps.

Step 9 Ċ On the Operator Station put the START/STOP

rocker switch in the STOP position. Put the POWER ON/

OFF circuit breaker in the OFF position. Open the main

aĆc line disconnect switch.

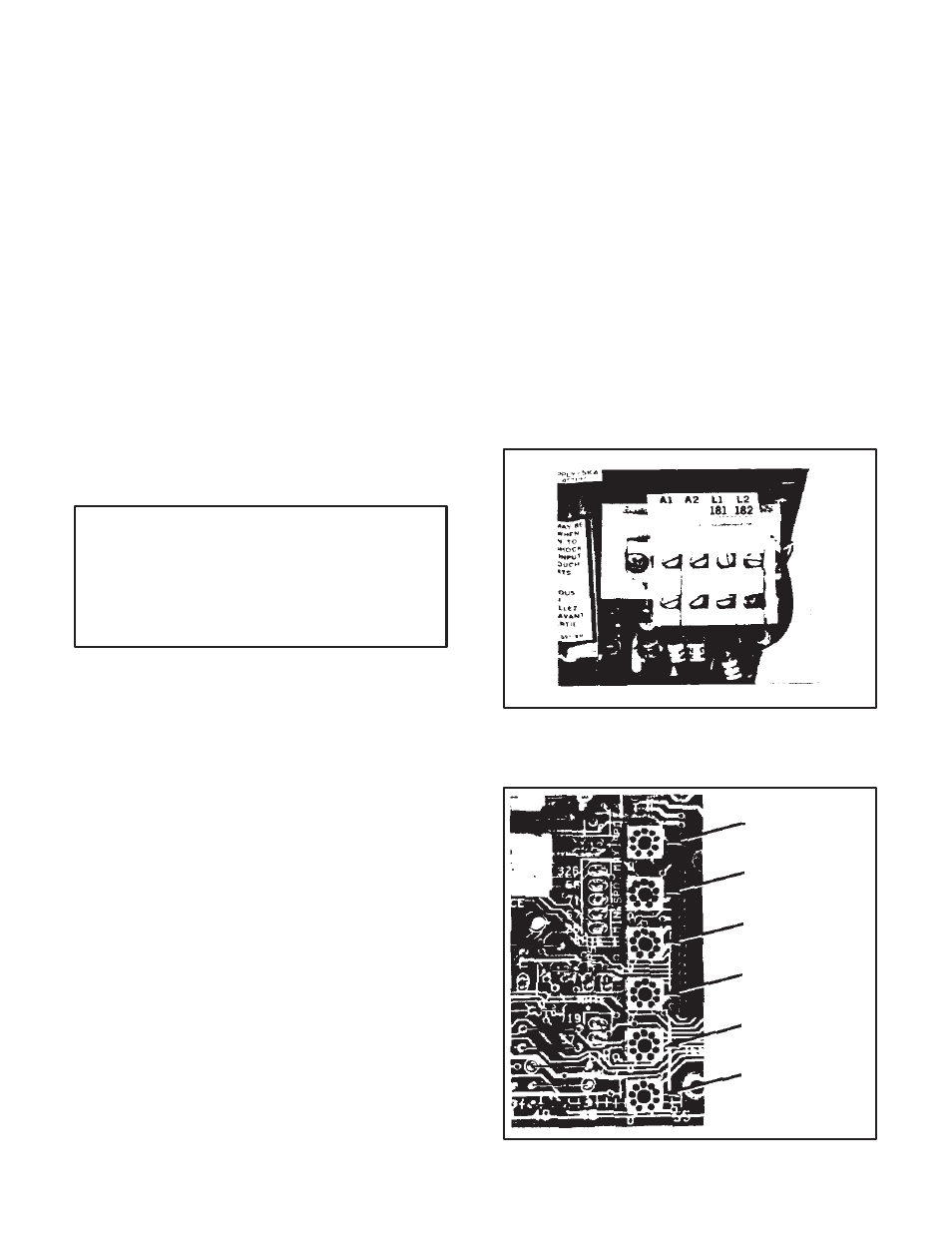

Step 10 Ċ Open the Cover and locate terminal barrier

1TB. (Refer to Figure 4.6.) Locate terminals A1 and A2,

which are the conductors connected to the armature. ReĆ

verse the position of these conductors.

Step 11 Ċ Return to Step 1 and. at Step 9, observe the

direction of shaft rotation to confirm proper turning and

motor performance.

Step 12 Ċ Do not turn any power off at this time. Go diĆ

rectly to Paragraph 4.3.4 and begin the setĆup adjustĆ

ments.

4.3.4 Regulator Module Pots Ċ The Regulator Module

has six adjustable potentiometers mounted on it. (Refer

to Figure 4.7.) They control the following functions:

D Maximum speed (full CCW: 50% speed)

D Minimum speed (full CCW: zero speed)

D Rate 1 (FORWARD acceleration, REVERSE decelĆ

eration)

D Rate 2 (REVERSE acceleration. FORWARD decelĆ

eration)

D Current limit #1 (+) (factory set at 150%)

D Current limit #2 (-) (factory set at 150%)

The pots are factory preset for the safest or most conserĆ

vative operation. At this time there should be no need to

make adjustments.

4.3.5 SpeedAdjustment Ċ The basic speed of the

drive is operatorĆcontrolled by the master speed potenĆ

tiometer.'' (This assumes that the AUTO/MANUAL is in

the MANUAL position.) The dial is located on the OperaĆ

tor Station and is marked SPEED.

Adjustments can be made with this control when the

drive is at rest or running.

When the drive is started, it automatically accelerates to

the speed selected on the SPEED dial. The numbers 1

thru 10 represent percentages of maximum speed.

Figure 4.6 - Terminals A1, A2 on 1TB

Max Speed

Min Speed

Rate 1

Rate 2

Current Limit 1

Current Limit 2

Figure 4.7 - Regulator Module Pots