Rockwell Automation MinPak Plus DC Drives Kits User Manual

Page 17

16

Table 3.D - HORSEPOWER CALIBRATION

MOTOR HP

MOTOR CURRENT/

PIN CONNECTIONS

115 VAC

230 VAC

PIN CONNECTIONS

1/4

1/3

1/2

3/4

Ċ

Ċ

Ċ

1/2

3/4

1

1Ć1/2

2

3

5

ă2.5A

ă3.7A

ăĂă5A

ă7.5A

10A

15A

25A

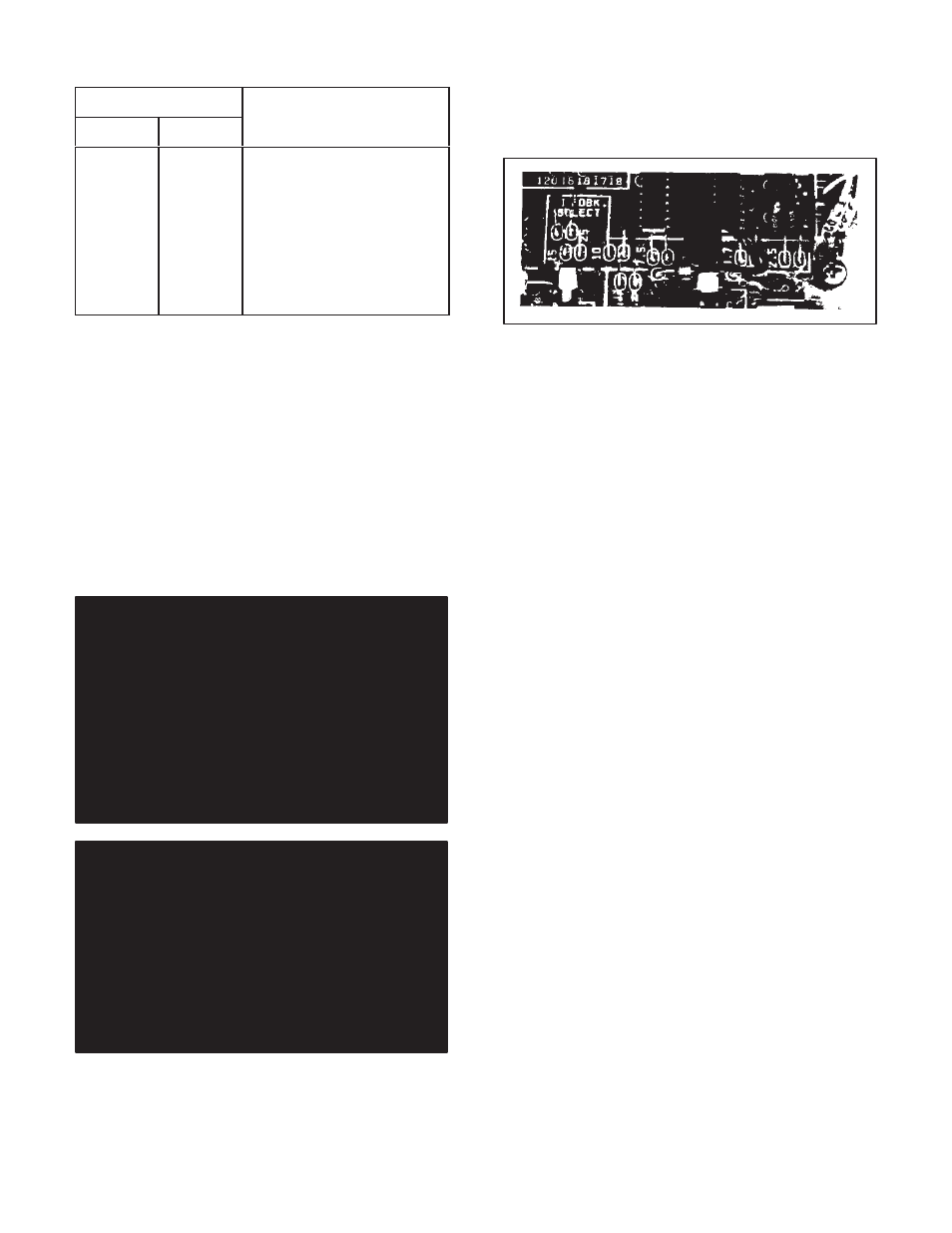

Step 3 Ċ On the Regulator Module, locate the scaling

pins. (Refer to Figure 3.11.) Near them, locate the black

pigĆtail type jumper. Do not move it if it is connected to the

proper pair of pins. If it must be reconnected, carefully lift

it straight up and off the pins. Slide the connector

straight down over the proper set of pins.

Figure 3.11 - HP/Current Scaling Pins

Section 4

STARTĆUP AND ADJUSTMENT

4.0 General Ċ This Section provides startĆup and adĆ

justment procedures to be followed after the assembly

and installation of the controller is complete. All initial opĆ

eration checks and final adjustments to the controller

must be made in conformance to the procedures, warnĆ

ings and recommendations listed here.

DANGER

THE REGENERATIVE MINPAK PLUS CONTROLĆ

LER IS ATLINE VOLTAGE WHEN AĆC LINE POWĆ

ER IS CONNECTED TO THE POWER UNIT INĆ

SIDE THE CONTROLLER. THE OPERATOR'S

POWER ON/OFF CIRCUITBREAKER DOES

NOTREMOVE AĆC LINE POWER FROM THE

UNIT. BEFORE WORKING ON, OR T OUCHING

ANY INTERNAL PARTS F, THE CONTROLLER,

REMOVE INCOMING AĆC LINE POWER ATTHE

MAIN DISCONNECTSWITCH. PERSONAL INĆ

JURY MAY RESULTIF THIS IS NOTFOLLOWED.

DANGER

DURING INITIAL STARTĆUP, THE CONTROLLER

AND ITS ASSOCIATED EQUIPMENT MUST BE

OPERATED AND/OR ADJUSTED ONLY BY

QUALIFIED ELECTRICAL MAINTENANCE PERĆ

SONNEL. THESE INDIVIDUALS SHOULD BE FAĆ

MILIAR WITH THE DESIGN AND OPERATION

OF THIS EQUIPMENT AND WITH THE HAZARDS

INVOLVED. PERSONAL INJURY AND/OR DAMĆ

AGE TO THE CONTROLLER COULD RESULT

FROM UNFAMILIARITY.

Figure 4.1 indicates typical areas in the controller that

should be examined as noted in these paragraphs.

4.1 Power Off Inspection Ċ It is necessary to make a

superficial inspection of the Regenerative MinPak Plus

controller and its associated units. The purpose of this

check is to look for possible physical damage or impropĆ

er connections. These procedures assume that the aĆc

incoming line is locked off and that the load is uncoupled

from the motor.

Step 1 Ċ Inspect the firmness of motor connections.

There should be no broken insulation on power cables

since conductor grounding could cause damage. Make

sure the ground strap between the motor frame and plant

(earth) ground is firmly fixed.

Step 2 Ċ If a formal installation and wiring inspection

was not carried out, it is recommended that an extensive

one be done before any other startĆup procedures are

followed. (Discovery of wiring errors and/or improper or

incomplete assembly will save valuable time later. Refer

to the specific System's layout prints.)

Step 3 Ċ Even if there had been a final inspection, inĆ

spect all wiring, aĆc incoming, dĆc outgoing, feedback,

signal and grounding, for proper and firm connections

Any connection error in wiring can cause damage or a

malfunction when power is applied. Any short to building

ground in signal wiring can also cause damage. Make

sure the open panel or the enclosure is connected to

plant (earth) ground.

Step 4 Ċ Make a final check that the plant power supply

feeding the aĆc line is the proper voltage and frequency.

Step 5 Ċ Use an ohmmeter to determine if a ground exĆ

ists between aĆcinput conductors and the Chassis. Also

determine if a ground exists between dĆcoutput conducĆ

tors and the Chassis. If a ground exists, it must be found

and removed before proceeding.