Rockwell Automation MinPak Plus DC Drives Kits User Manual

Page 28

27

Table 6.B - LOCAL OPERATOR'S CONTROL FACEPLATES

SPECIFY

OPERATOR'S

FUNCTIONS PROVIDED➀

WHEN USING A

MINPAK PLUS

CONTROLLER WITH:

OPERATOR'S

CONTROL

FACEPLATE

MODEL

START/

STOP

SPEEDĆ

SETTING

POT

TORQUEĆ

SETTING

POT

RUN/JOG

SELECTOR

FORWARD/

REVERSE

SELECTOR

AUTOMATIC/

MANUAL

SELECTOR

D Blank Faceplate

(Use with Remote

Station)

D Basic features plus

armatureĆreversing

D Basic features plus

armature-reversing

and automatic/manual

modes of operation

D Basic features plus

armature-reversing

and torque control

D Basic features plus

armature-reversing,

torque control and

automatic/manual

modes of operation

14C200

14C202

14C204

14C206

14C208

no

yes

yes

yes

yes

no

yes

yes

yes

yes

no

no

no

yes

yes

no

yes

yes

yes

yes

no

yes

yes

yes

yes

no

no

yes

no

yes

➀

POWER ON/OFF circuit breakers standard with Chassis.

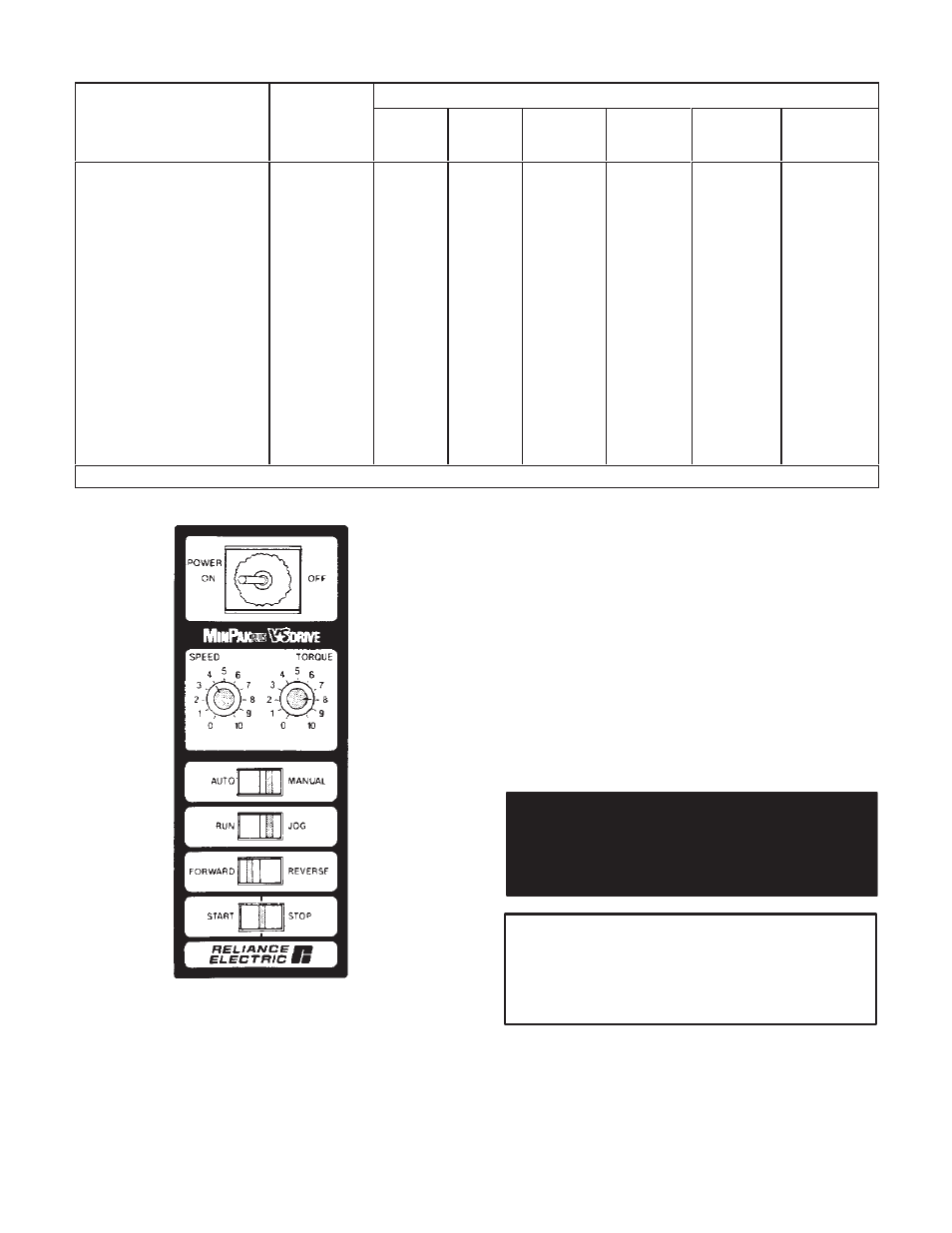

Figure 6.2 - Local Faceplate with All Options

Installation procedures are explained here.

Step 1 Ċ Align the Faceplate's POWER ON/OFF cutout

to fit over the circuit breaker lever.

Step 2 Ċ Pass the two wire harnesses through the Cover

cutout, align the threaded studs with the holes, and press

the Faceplate into place. Check for an even seating on

the gasket.

Step 3 Ċ Attach and tighten all eight keps nuts until the

Faceplate bottoms out on the stops built into the Cover.

Use an alternating pattern when tightening, but tighten

all nuts evenly. Attach the ground (green) wire to the

Faceplate with the standard hex nut provided.

DANGER

IT IS NECESSARY TO ATTACH THE FACTORĆ

SHIPPED GROUND WIRE TO THE COVER OF

THE CONTROLLER. PERSONAL INJURY MAY

RESULT IF THIS PRACTICE IS NOT FOLLOWED.

CAUTION: If the Operator's Control Station FaceĆ

plate is not properly seated and firmly tightened,

the NEMA Type 4 rating of the controller cannot be

maintained. Make sure there is a firm seating

against the gasket.