Rockwell Automation MinPak Plus DC Drives Kits User Manual

Page 11

10

Use a 1Ćinch copper braid or an 8 gauge wire and conĆ

nect with the plant (central) ground.

The motor frame should also be grounded. In many

cases it is adequate to use a screw in the conduit box

near the motor .

Guideline 19 Ċ A thermostat is used to guard against

motor overload protection. It is essential to properly conĆ

nect the motor thermostat in series with the Operator's

Control Station STOPselector switch at connections 32

and 132. (Refer to Paragraph 3.6 for specific details. ReĆ

fer also to Figure 3.8 in which a typical Operator's Control

Station schematic is shown.)

Guideline 20 Ċ When planning signal or control wire

runs, as listed in Table 6.C, follow these practices:

D Conduits should be steel.

D If these conduits cross 440 VAC conductors, make

sure the cross is at 90

°

.

D Do not route signal wires through junctions or

terminal boxes that contain nonĆsignal aĆc or dĆc

(115/230/460 V) wires.

Guideline 21 Ċ Operational altitude above sea level

may not exceed 3300 ft (1000 m). Derate horsepower 3%

for each 1000 ft (300 m) above this altitude.

3.2 Mounting Ċ This Paragraph outlines the proceĆ

dures to be followed in order to mount the Regenerative

MinPak Plus controller . It assumes that a layout plan exĆ

ists and that Guidelines 1, 2, 3, 4, 5, 7 and 9, noted in

Paragraph 3.1, have been considered.

The three largest components of the Regenerative MinĆ

Pak Plus controller are the Chassis, the Cover and a CovĆ

er Faceplate. The first two items are standard; the third

is specified and ordered as an option.

If the Cover is not being used, it should be removed beĆ

fore mounting begins. (It may be unfastened at the

hinges.)

CAUTION: The controller design requires that the

Cover be lifted about 2 inches (50 mm) directly up

from the Chassis before it may be swung to one

side. Always be careful to lift it before hinging to the

side. Damage to the unit may result if this practice is

not followed.

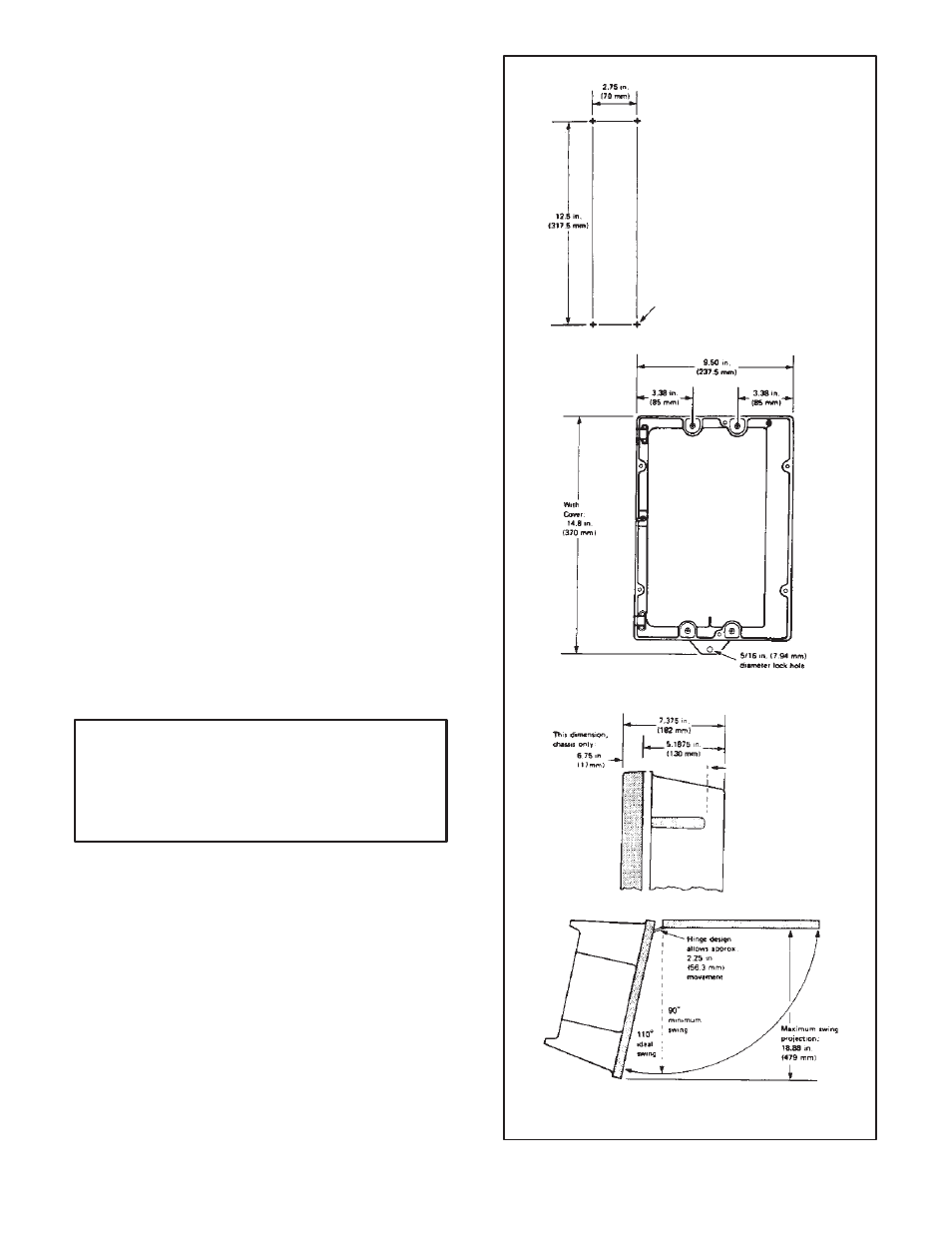

Determine the exact placement of the Chassis on the wall

or panel. (Refer to Figure 3.4 for mounting dimensions.)

Scribe the panel or mark the wall. Drill four holes large

enough to accept 1/4 inch mounting bolts. Scrape the

paint around the holes to allow washers and bolts to

make a ground contact.

Choose four 1/4"-20 lug bolts. Their length depends

upon the depth of the entire mounting surface. Because

of the Chassis design, only 1/8 inch (3 mm) is required

between the inside of the well and the outside edge of the

heat sink.

3.3 Grounding Ċ Proper grounding practices are esĆ

sential to assure personal safety, to guard against electriĆ

cal shocks to personnel who touch the exterior surfaces

of the controller or enclosures and to reduce the effects

of electrical noise interference on signalĆtype circuits.

There are two basic types of grounds: earth and chassis.

a) mounting drill plan

b) overall dimensions

c) side view

d) top view

Scrape

paint

around

holes

to assure

grounding.

Drill 4

holes

for 1/4” – 20

lug

screws.

Figure 3.4 - Mounting Dimensions