Rockwell Automation MinPak Plus DC Drives Kits User Manual

Page 5

4

D Order a Remote Operator Adapter Kit, Model

14C220. (This unit provides a connection point for

the Remote Station .)

D Specify a Reliance Electric Remote Operator ConĆ

trol Station. Connect it to the controller.

Reliance Electric offers a variety of Remote Operator StaĆ

tions that are compatible with the Regenerative MinPak

Plus controller. (Refer to Table 2.B.)

2.2 DĆC Drive Motors Ċ The third component of the ReĆ

generative MinPak Plus DĆC VKSdrive system is the dĆc

motor. Reliance Electric offers a completely powerĆ

matched drive system for the controller and the applicaĆ

tion. Thus the choice of Reliance Electric motors assures

optimum performance and unmatched singleĆsource reĆ

sponsibility.

2.3 Modification Kits Ċ The basic capability of the conĆ

troller can be quickly and conveniently extended with the

use of a variety of optional Modification Kits. (Refer to FigĆ

ure 2.2.) These are:

D Dynamic Braking

D Voltage/Tachometer Follower

D Instrument Interface/Preset Speed

D Field Supply (Standard on 2, 3 and 5 hp controllers)

D Auxiliary M Contact

D Test Meter Adapter

D Master Isolated Reference Receiver

D Dancer Follower

Complete descriptions of each Kit are given in Section 6.

Refer also to Table 6.A.

2.4 Specifications Ċ The more important specificaĆ

tions for the Regenerative MinPak Plus controller are

listed in Table 2.C. Refer also to Table 2.D where other

ratings are indicated in relation to dĆc motors of specific

horsepower.

2.4.1 Line Frequency Ċ The Regenerative MinPak Plus

controller is able to operate without modification from a

singleĆphase power source having a frequency range

from 48 to 62 Hz. However, for optimum 50ĆHz operation,

it is recommended that two resistors be removed from

the Regulator Module. (Complete details are given at

Paragraph 3.9.) If the resistors are not removed, there is

a slight loss of performance.

2.4.2 Voltage Tolerance Ċ The Regenerative MinPak

Plus controller delivers output current and voltage as

listed in Table 2.D. It will also operate within these regulaĆ

tion specifications even with incoming line voltage at

"10% of nominal. Furthermore, the controller will operĆ

ate without component damage during momentary input

voltage dips down to 25% of nominal.

2.4.3 Line Impedance Requirements Ċ The standard

Regenerative MinPak Plus controller contains a shortĆcirĆ

cuit protection system designed to operate on plant

power supplies with maximum permissible available

symmetrical RMSfault currents of either 1000 or 5000

amperes, depending on the horsepower rating. (Refer to

Table 2.D.)

WARNING

DO NOT OPERATE THE REGENERATIVE MINĆ

PAK PLUSCONTROLLER ON POWER SUPĆ

PLIESWITH AVAILABLE SHORTĆCIRCUIT CURĆ

RENTSIN EXCESSOF 1000 AMPERESFOR

RATINGSOF 1 HP, OR LESS, AND 5000 AMĆ

PERESFOR RATINGSGREATER THAN 1 HP.

DAMAGE TO EQUIPMENT AND PERSONAL INĆ

JURY MAY OCCUR.

2.5 NEMA Definitions Ċ NEMA Type 4 is generally deĆ

fined as an indoor/outdoor enclosure that is watertight

and dusttight. It is designed to protect against splashĆ

ings and hoseĆdirected water within specific test limitaĆ

tions.

NEMA Type 12 is generally defined as an indoor encloĆ

sure that is dusttight and oiltight. It is designed to resist

fibers, flyings, dust, dirt and light oil splashings.

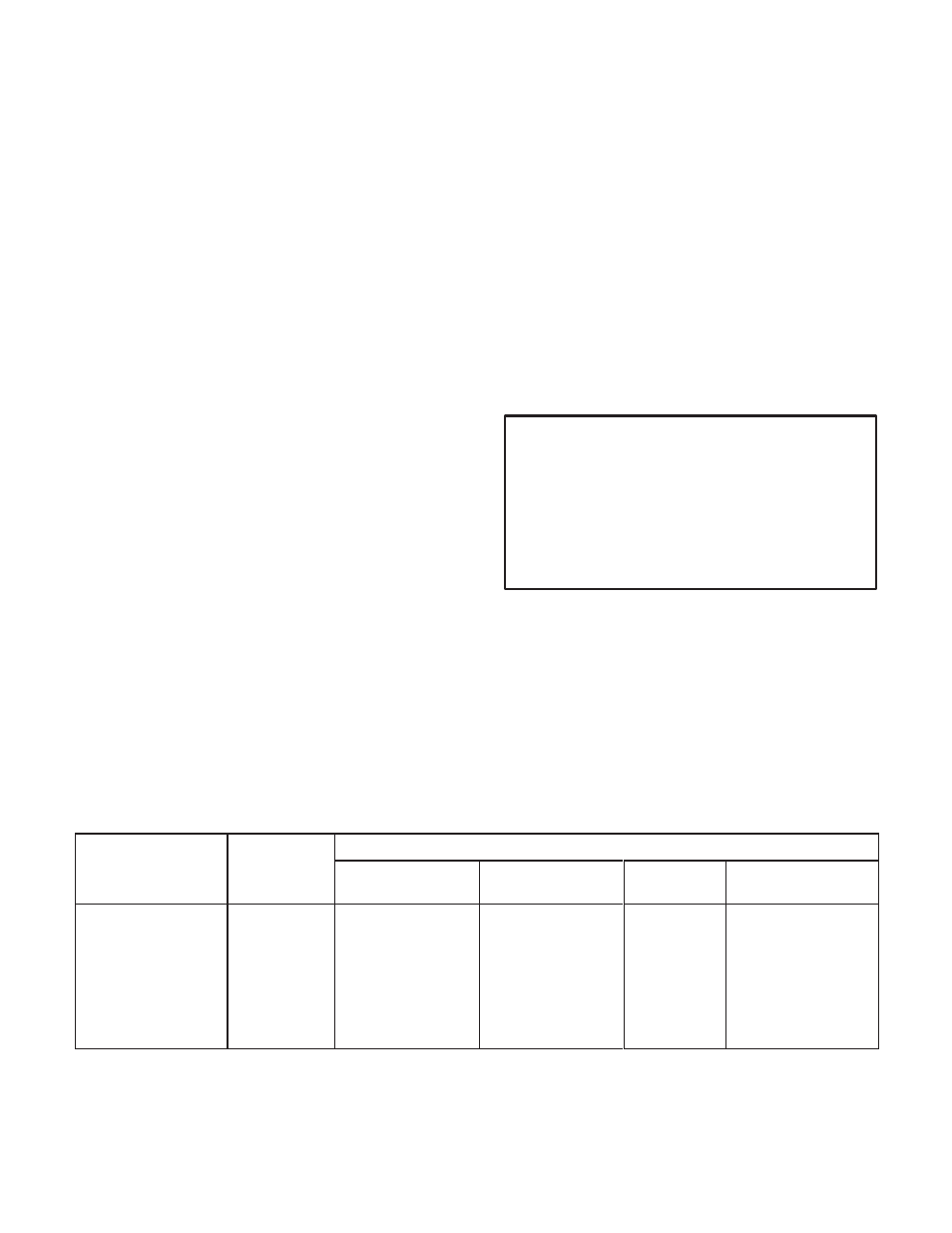

Table 2.B - REMOTE OPERATOR CONTROL STATIONS

WHEN USING A

REGENERATIVE

SPECIFY

OPERATOR'S

FUNCTIONSPROVIDED

REGENERATIVE

MINPAK PLUS

CONTROLLER WITH:

OPERATOR'S

STATION

MODEL

START/STOP

ROCKER SWITCH

SPEED SETTING

POTENTIOMETER

RUN/JOG

SELECTOR

FORWARD/REVERSE

SELECTOR

Basic features plus

armature reversing

(standard reversing

Station)

NEMA Type 4 Station

for reversing

ExplosionĆproof

Station for reversing

9C46

9C19

9C16

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes