Rockwell Automation MinPak Plus DC Drives Kits User Manual

Page 19

18

If aRemote Station is used. aseries of wires will connect

to individual terminals on a strip mounted on the Remote

Operator Interface Module. (This Module is mounted on

the Regulator Module. Refer to Figure 4.1.) Determine

that all wires are firmly seated in the terminal strip. Make

sure all wires are connected.

4.2.2 50ĆHz Resistors Ċ Although the Regenerative

MinPak Plus operates without modification with a 50ĆHz

frequency input, there are performance advantages if

two resistors are removed. If 50ĆHz operation is exĆ

pected, make sure the resistors are removed. (Refer to

Figure 3.10.)

4.2.3 Regulation Mode Jumper Ċ The Regenerative

MinPak Plus controller offers two types of drive regulaĆ

tion. The first, which is factory shipped, is an armature

voltage feedback (A). Optionally, the user may use

tachometer feedback (T). In order to use the tachometer

feedback, the Regulation Mode Jumper, one end of

which is permanently fixed to the Regulator Module,

must be moved to the T" position. (Refer to Figure 3.9.)

Details of Jumper placement are noted in Section 3.

DANGER

IF YOU ARE UNSURE WHICH REGULATION

MODE A CONTROLLER SHOULD HAVE, IT IS

IMPORTANT YOU FIND OUT. IF THE JUMPER IS

NOT PROPERLYCONNECTED, PERSONAL INĆ

JURYMAYRESULT.

4.2.4 Remote Station, Tachometer Grounds Ċ When

a Remote Operator Station or a tachometer device or an

instrument interface device is being used. it is necessary

to carefully check for possible grounds between the metĆ

al base and the magnetic control circuits. This procedure

should be followed only if one of the three devices is beĆ

ing used. (If the Operator Station switches are mounted

on the Regenerative MinPak Plus controller's Cover, do

not follow this procedure. If there is no tachometer or

instrument interface device. do not follow them.)

CAUTION: Do not use amegger to perform these

checks since some electrical circuits connected to

test points could be damaged by the high voltage of

the megger.

CAUTION: A ground between the control circuits or

associated wires and the grounded parts of the

controller will cause improper operation. Follow

this procedure carefully.

Step 1 Ċ On an ohmmeter, set up for an R x 100,000

scale.

Step 2 Ċ Connect one ohmmeter lead to the controller's

Chassis to make a simple resistance check.

Step 3 Ċ On the Remote Operator Module, touch the

test probe to each screw terminal on the terminal strip.

Do this in an orderly fashion. (Refer to Figure 4.3.) If a

reading to ground on any terminal is less than 100,000

ohms, aground condition exists in this circuit.

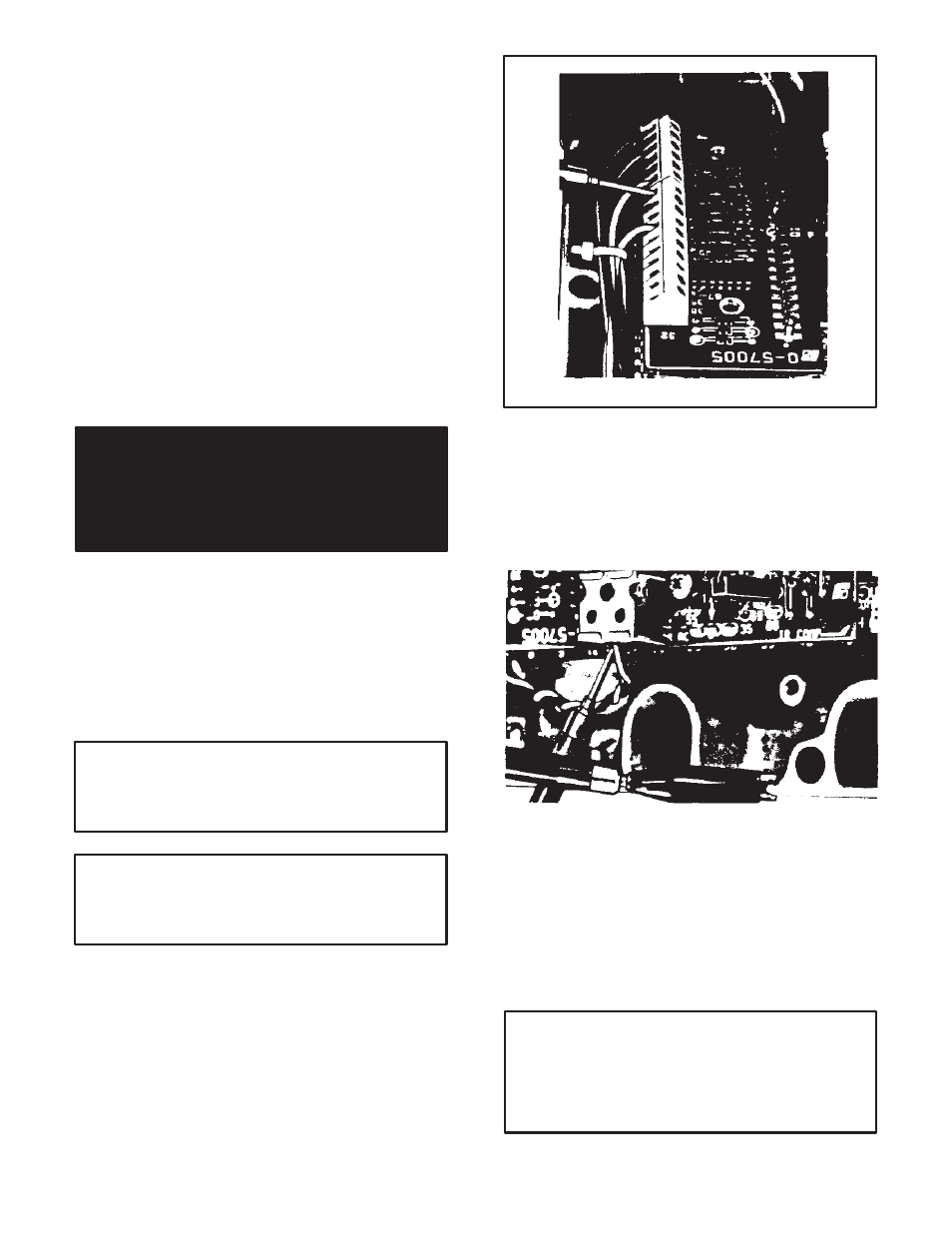

Figure 4.3 - Testing Remote Module

Step 4 Ċ On the Tachometer Feedback Module, touch

the two screw terminals, (+,-) on the terminal strip. (ReĆ

fer to Figure 4.4.) If the reading to ground on either termiĆ

nal is less than 100,000 ohms, a ground condition exists

in this circuit.

Figure 4.4 - Testing Tachometer Feedback

Step 5 Ċ Should aground condition be found, consult

the wiring diagram in Figure 3.8. Examine both ends of

the signal wires for bare wire touching. (This may be due

to excess stripping or insulation breaks.)

4.2.5 Motor Ground Check Ċ It is necessary to make

a check of the drive motor to assure that no damaging

groundsĊother than earth groundĊexist with in the

motor.

CAUTION: Although amegger may be used for this

test, if one is used, all conductors between the drive

motor and the Regenerative MinPak Plus controller

are to be disconnected and moved aside. The high

voltage of the megger can cause damage to the

controller's circuits.