Rockwell Automation MinPak Plus DC Drives Kits User Manual

Page 37

36

Step 4 Ċ Using three twisted wires, connect the user

supplied 5 K ohm Dancer potentiometer to the terminal

strip of the Dancer Follower Module. The speed inĆ

crease side of the potentiometer connects to terminal

556 and the speed decrease side connects to terminal

571. The potentiometer wiper is connected to terminal

919.

Step 5 Ċ If an optional Dancer Position potentiometer

is used (supplied by user), connect the up'' side of the

potentiometer to terminal 726 of the Dancer Follower

Module and the down" side to terminal 557. Connect

the potentiometer wiper to terminal 926. Also cut and reĆ

move jumper J2 and the 26.7 K resistor (R6) on the

Dancer Follower Module. (Refer to Figure 6.20.)

Step 6 Ċ If an AUTO/MANUAL selector switch is used

on the Operator Control Station, remove jumper J1 of

the Dancer Follower Module. (Refer to Figure 6.20.) If,

however, the controller is to run automatically without

manual speed control, leave J1 in place.

Step 7 Ċ This Step assumes that the complete drive

system, including the controller, has been successfully

started and debugged according to Section 4 thru ParaĆ

graph 4.4.1. It is now necessary to conduct a powerĆon

test.

Start the drive and place it in the AUTO mode, if so

equipped. With the line speed reference at maximum

value, adjust the MAX SPEED TRIM potentiometer on

the Dancer Follower Module for maximum motor speed.

If the optional Dancer Position potentiometer is

installed, place it in the midĆrange.

Turn the GAIN potentiometer of the Dancer Follower

Module fully counterclockwise for minimum Dancer poĆ

tentiometer response. Turn the GAIN potentiometer

clockwise in small increments to increase the Dancer poĆ

tentiometer response.

DANGER

APPLICATION MUST NOT RELY ON ZERO

SET/INPUT SETTING FOR SAFETY. SERIOUS

ORFATAL INJURY MAY RESULT.

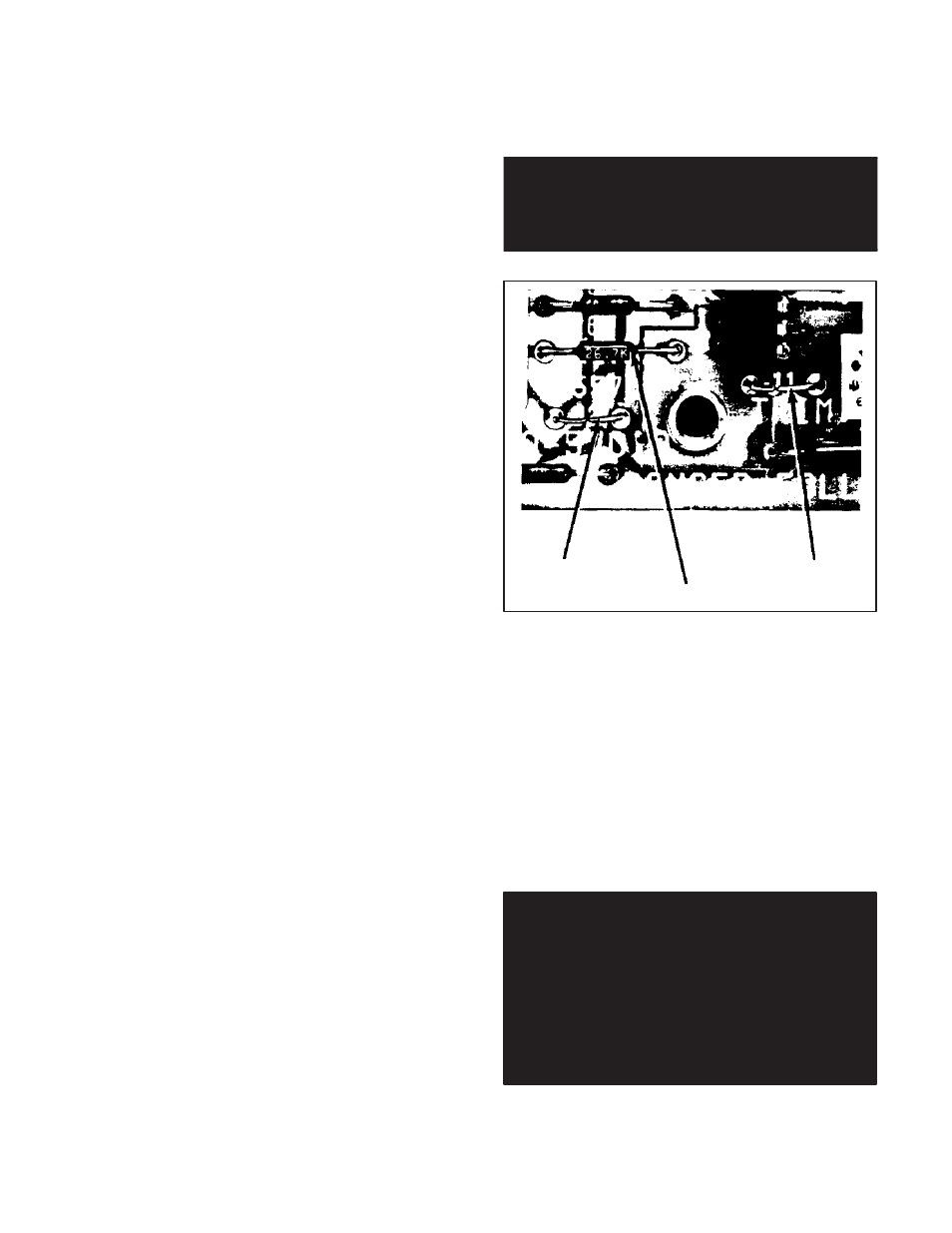

Resistor (R6)

Jumper J2

Jumper J1

Figure 6.20 - Jumpers J1, J2 and Resistor (R6)

Section 7

TROUBLESHOOTING

7.0 General Ċ This Section details troubleshooting inĆ

formation for the Regenerative MinPak Plus controller. Its

organization is as follows:

D General troubleshooting concepts (Par. 7.1, 7.2,

7.3, 7.4)

D Specific symptom/probable cause/recommended

procedures (Par. 7.5)

D Reference schematics of the controller (Par. 7.6)

DANGER

CONTROLLER EQUIPMENT IS AT LINE VOLTĆ

AGE WHEN AĆC POWERIS CONNECTED TO

THE POWER UNIT IN THE REGENERATIVE MINĆ

PAK PLUS CONTROLLER. THUS AĆC POWER

MUST BE REMOVED FROM THE UNIT BEFORE

IT IS SAFE TO TOUCH THE INTERNAL PARTS

OF THE REGENERATIVE MINPAK PLUS. PERĆ

SONAL INJURY MAY RESULT UNLESS POWER

IS REMOVED.