Rockwell Automation 1771-QC , D17716.5.25 SER/B SERVO POS User Manual

Page 121

Formatting and Interpreting Data Blocks

Chapter 7

7Ć39

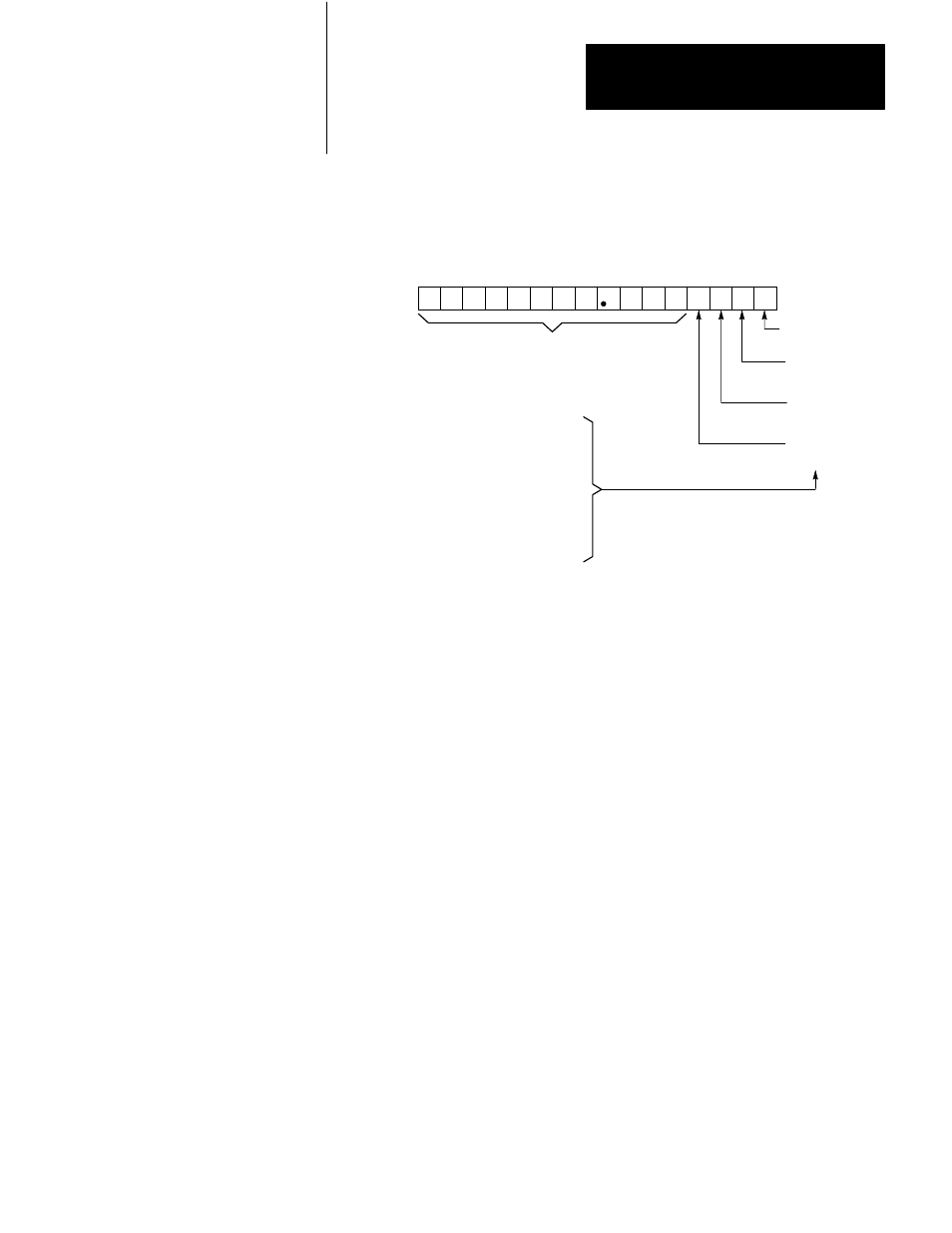

Figure 7.28

Following Error Reduction/Tachometer Conversion Factor Word

17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

FE Reduction, Tach Conversion Factor

Word 25 (Axis 1)

Word 44 (Axis 2)

Word 63 (Axis 3)

11050

BCD following error reduction value (0-99.9%)

0 = 0

1 = 0.0625

0 = 0

1 = 0.125

0 = 0

1 = 0.250

0 = 0

1 = 0.500

Total value is the sum of the

selected values.

Used if full scale analog output

voltage is greater than tachometer

voltage for a given rpm. Refer to

the tachometer calibration

procedure in chapter 9.

Each of bits 0 thru 3 corresponds to a factor. The total factor used by

loss-of-feedback detection equals the sum of the individual factors

selected.

If you are not using the loss-of-feedback detection feature, or if

tachometer voltage is greater than or equal to 10V, program zero for all

bits of this word.

Following Error Reduction

The servo positioning assembly accepts the BCD value you enter into bits

04 thru 17 as the following error reduction value (Figure 7.28).

You can command a reduction of the following error by 0 through 99.9%.

The 1771-ES expander reduces the following error through feed

forwarding without increasing the positioning loop gain.

Consider an example in which you have entered an initial gain value of

1.00. With an axis speed of 10 ipm, without following error reduction, the

following error would be 10 mils.