20 troubleshooting – Rockwell Automation 1557 MEDIUM VOLTAGE AC DRIVE User Manual

Page 262

10-20

TROUBLESHOOTING

1557-UM050F-EN-P – June 2013

MACHINE SIDE CONVERTER AND LINE SIDE CONVERTER

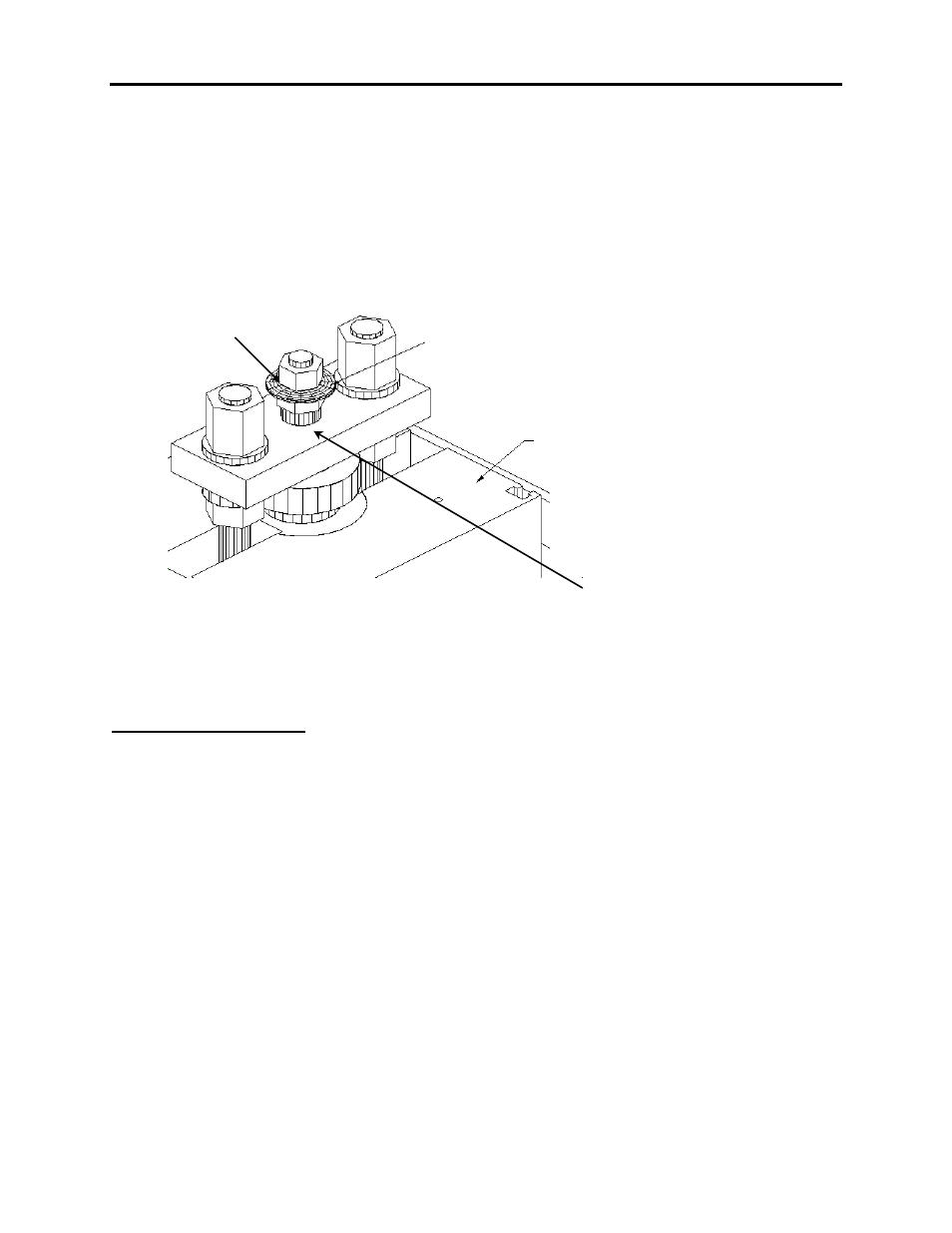

There are two disc springs located top and center of the clamp pressure bar assembly (not to be confused

with the larger diameter disc springs below the pressure bar assembly ). The disc springs should just be

able to turn with finger touch (see Figure 10.2).

Figure 10.2

– Checking Clamp Force – Machine Side Converter and Line Side Converter Modules

Adjusting Clamp Pressure

If clamp forces have been checked and increasing the clamp force is required, the following procedures

should be used.

SNUBBER DIODE

To increase the clamp pressure, torque the M8 bolts in the insulation cups (13-mm wrench). Turn the first

bolt 1/4 turn and then torque the other bolt 1/4 turn, check the tabwasher. Repeat this procedure until the

tabwasher can just rotate with finger touch.

MACHINE SIDE CONVERTER AND LINE SIDE CONVERTER

To increase the clamp pressure, torque only the adjusting nut below the two indicating disc springs shown

in Figure 10.2 (21 mm open end wrench). Turn adjusting nut 1/4 turn, check the indicating disc springs.

Repeat until the indicating disc springs can just rotate with finger touch.

Never rotate

this nut

Heatsink (Simplified view)

Indicating

Disk Springs

Tension Adjusting Nut