10 troubleshooting – Rockwell Automation 1557 MEDIUM VOLTAGE AC DRIVE User Manual

Page 252

10-10

TROUBLESHOOTING

1557-UM050F-EN-P – June 2013

Power Semiconductor Testing

If you suspect that a problem may exist with a power semiconductor follow the steps below to help identify

a suspicious device.

WARNING: Before attempting any work, verify the system has been

locked out and tested to have no potential.

1. Using an ohmmeter, measure the anode to cathode, anode to gate, and cathode to gate. The

resistance in circuit will differ from out of circuit where other assemblies provide a parallel path.

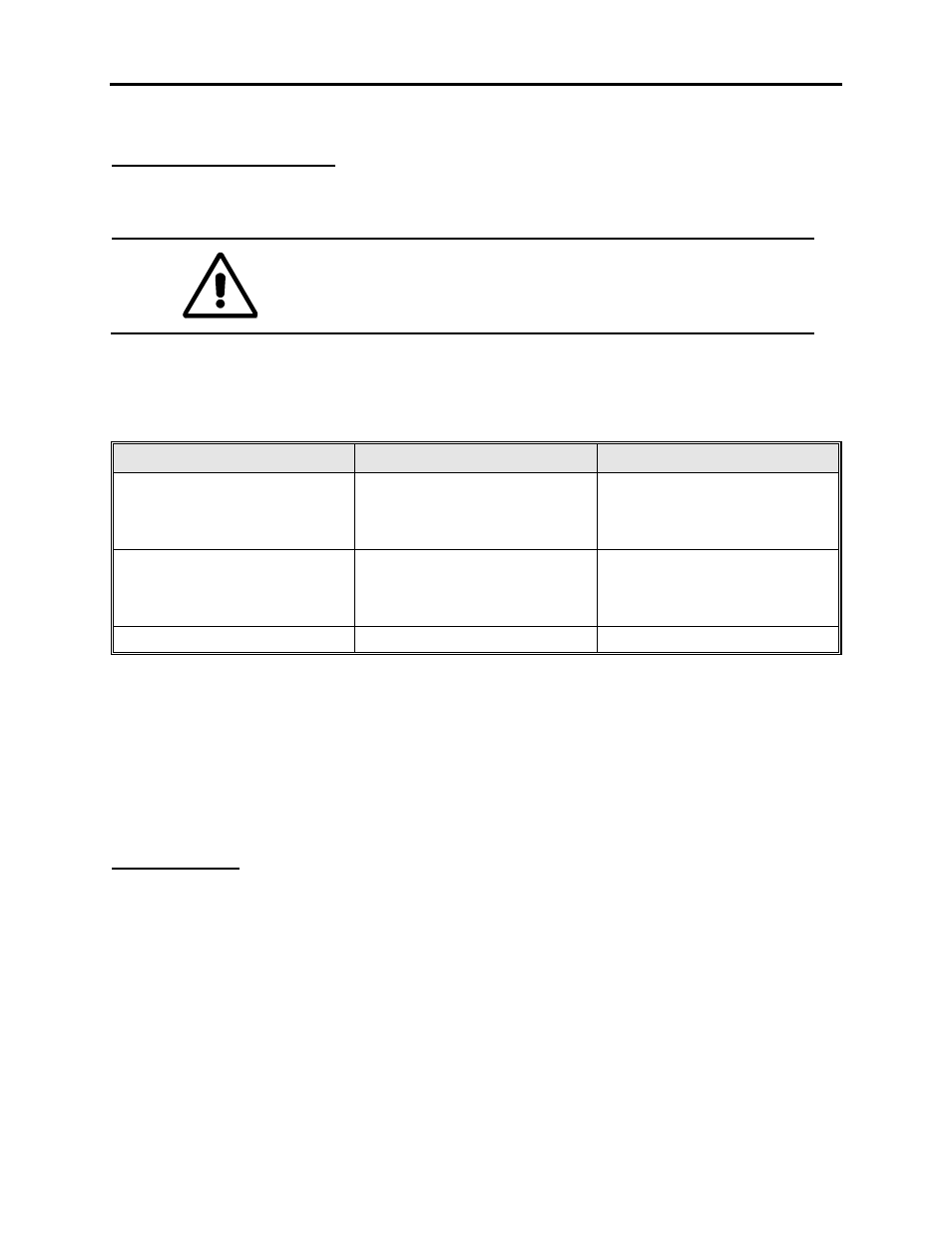

DEVICE

TEST POINTS

EXPECTED MEASUREMENT

GTO

ANODE TO CATHODE

ANODE TO GATE

CATHODE TO GATE

10.3K

10.3K

10

SCR

ANODE TO CATHODE

ANODE TO GATE

CATHODE TO GATE

23.5K

23.5K

12

DIODE

ANODE TO CATHODE

10

Please note the actual resistance measurement will depend upon the device and the ohmmeter used. It is

not possible to accurately measure unclamped semiconductor devices.

2. If a short is found isolate the device on the stack and verify that indeed the device is faulty, only then

proceed with removing the stack from the drive.

3. If the semiconductor device is not suspected of being faulty, test other surrounding components, or

call your local RA/AB service representative for assistance.

Thyristor Clamps

Thyristor clamps are used to maintain the required contact force for the power semi-conductors. A pre-

calibrated force is exerted on the contact area of the semi-conductors, The force is exerted by a pre-set

load in the stack of disc springs at the head of the clamp. There are three different clamps used in each

1557 drive:

SNUBBER DIODE

Quantity of clamps voltage dependent.

MACHINE SIDE CONVERTER STACK

Quantity of clamps = 6

LINE SIDE CONVERTER STACK

Quantity of clamps = 3