12 commissioning – Rockwell Automation 1557 MEDIUM VOLTAGE AC DRIVE User Manual

Page 212

9-12

COMMISSIONING

1557-UM050F-EN-P – June 2013

4. The following mechanical checks should be carried out and the drive is inspected for shipping damage.

a. Torque all bolts and screws as required.

b. Check all wires and lugs for signs of stress and wear

c. Make sure all grounds are permanent and secure

d. Check all phasing to the drive. This is especially important if the system is a 12 or 18 pulse or has

bypass.

5. Check all interlocks and Kirk Key switches. If these are not functioning properly, it should be reported to

the factory immediately.

6. Check for protective barriers that may have been removed during installation or shipment.

7. Inspect the following for value with an ohmmeter.

a. Check all power resistors. Placement of these resistors may be viewed in the Hardware description

earlier in this manual.

b. Check all power semiconductors (SCRs, GTOs)

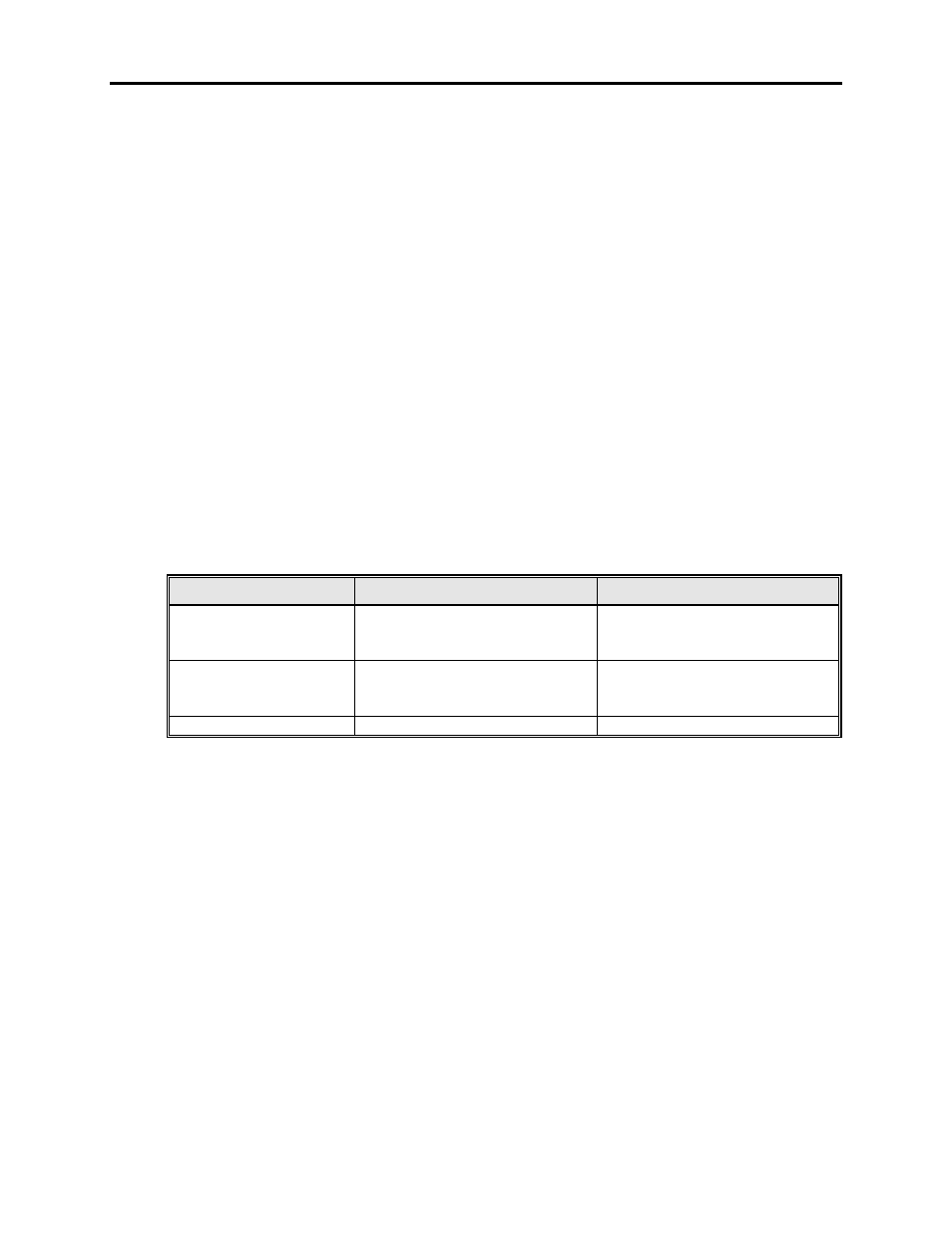

c. Using an ohmmeter, measure the anode to cathode, anode to gate, and cathode to gate. The

resistance in circuit will differ from out of circuit where other assemblies provide a parallel path.

DEVICE

TEST POINTS

EXPECTED MEASUREMENT

GTO

ANODE TO CATHODE

ANODE TO GATE

CATHODE TO GATE

> 400K

> 400K

> 20

SCR

ANODE TO CATHODE

ANODE TO GATE

CATHODE TO GATE

> 2M

>2M

12

DIODE

ANODE TO CATHODE

20

Please note the actual resistance measurement will depend upon the device and the ohmmeter used.

It is not possible to accurately measure unclamped semiconductor devices.

If a short is found, isolate the device on the stack and verify that the device is faulty, only then proceed

with removing the stack from the drive.

If the semiconductor device is not suspected of being faulty, test other surrounding components, or

call your local Rockwell Automation service representative for assistance.