Discrete plc controller i/o data transfer – Rockwell Automation 1395 Multi-Comm Hardware/Software User Manual

Page 26

Chapter 3

Configuration & Interfacing

3–15

Discrete PLC Controller

Data required by the Drive on a continuously updated basis is transferred

I/O Data Transfer

using the I/O image table of the PLC Controller. The data transfer rate can

be determined using the standard conventions for I/O rack updates of

discrete I/O. Refer to the PLC Controller manual for details.

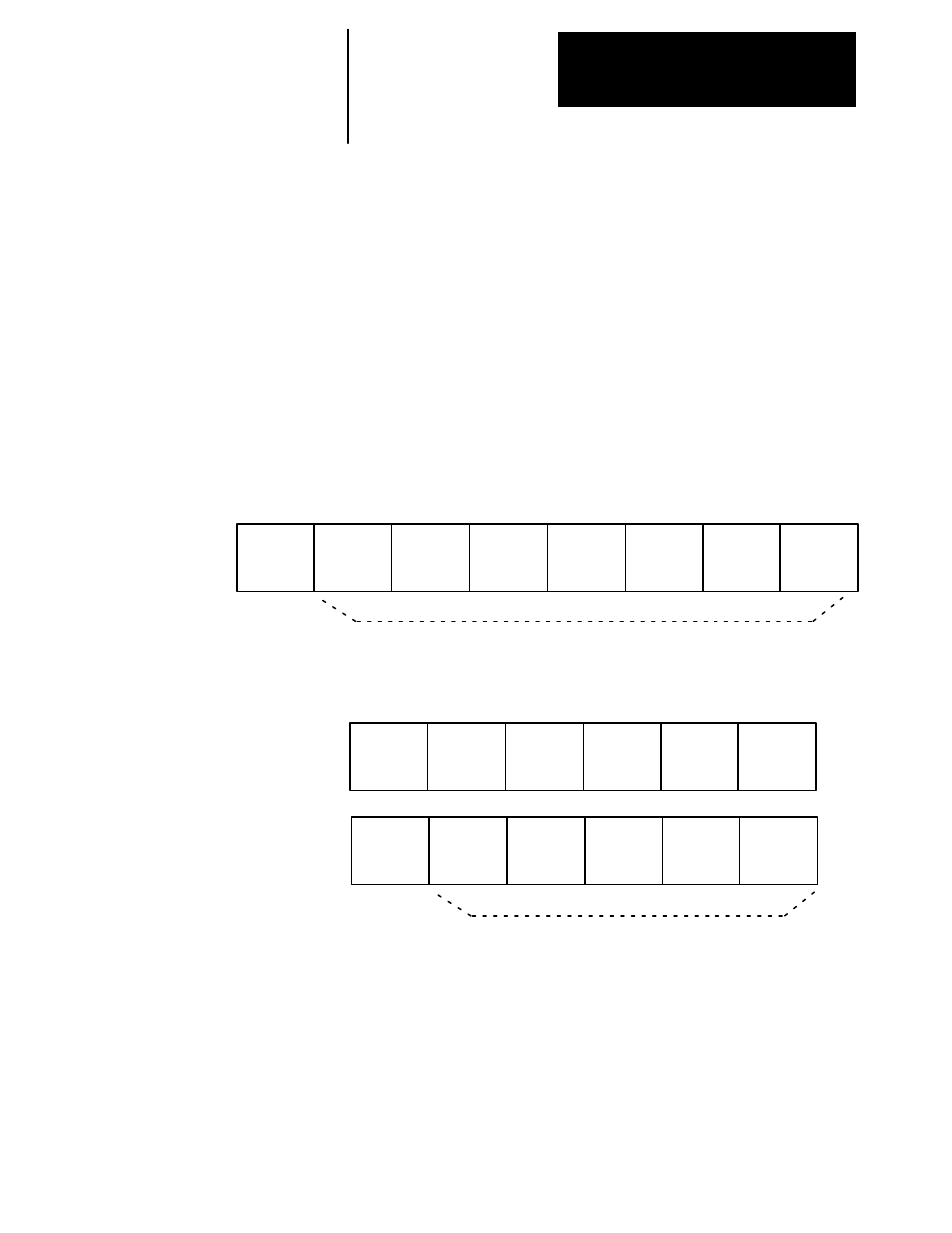

Refer to Figures 3–9 thru 3–11. These figures indicate how data is

transferred between the Drive and PLC controller for the rack size selected.

The first group number associated with a rack is reserved for the block

transfer function. The remainder of group numbers (1–7 for full racks, 1–5

or 3–7 for 3/4 racks, 1–3 or 5–7 for half racks) are used for the transfer of

discrete type data. Each group number reserves a single 16 bit word in both

the input and output image table of the PLC Controller for the rack number

assigned. In the Drive these words are directly linked to internal Drive

parameters using source and sink parameters as shown in Figure 3–12.

Figure 3-9. RIO Full Rack Configuration

Group 0

Groups 1–7 each appear (to the PLC Controller) to

have a 16 bit input and output module installed.

Group 1

Group 2

Group 3

Group 4

Group 5

Group 6

Group 7

Reserved

for Block

Transfer

Figure 3-10. RIO 3/4 Rack Configuration

Group 0

Group 1

Group 2

Group 3

Group 4

Group 5

Group 2

Each group appears to have a 16 bit input

and output module installed.

Group 3

Group 4

Group 5

Group 6

Group 7

Reserved

for Block

Transfer

Configured as 3/4 Lower Rack

Configured as 3/4 Upper Rack