Vicor VI-J00 Family DC-DC Converters and Configurable Power Supplies User Manual

Page 86

Design Guide & Applications Manual

For VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

VI-200 and VI-J00 Family Design Guide

Rev 3.5

vicorpower.com

Page 85 of 98

Apps. Eng. 800 927.9474

800 735.6200

23. Recommended Soldering Methods,

Tin Lead Pins, and InMate Sockets

Since there are so many factors that influence soldering

time, listing actual times is difficult. In general, it is

recommended that the joint be examined post-process to

ensure a quality soldering joint. If necessary, different

parameters can then be varied in order to ensure a solid

process. The soldering times listed in Table 23–1 can be

used as a guideline for establishing more application and

process-specific parameters. Below are some recommen-

dations for general practice:

1.

Do not run tip temperature above 750°F (400°C)

because it will greatly increase the risk of damaging

the pads, traces, printed circuit board, or Vicor power

module. Check with the printed circuit board

manufacturer for any additional recommendations

with regards to temperature.

2.

Apply the soldering iron to one side of the pin and

pad and apply the solder to the other, allowing the

heat from the pin and pad to melt the solder. Do not

apply solder to the soldering iron and subsequently

attempt to transfer it to the pad and pin. Melting the

solder by applying it directly to the soldering iron does

not guarantee adequate wetting on the joint and is

not considered good technique.

3.

Do not apply excessive pressure with the soldering

iron to the printed circuit board, barrel, or pad. This

could result in breaking a trace, dislodging a barrel or

damaging the PCB, which becomes noticeably softer

when heated.

4.

Do not apply the soldering iron to a connection for an

extended period of time or damage to the module

could result. If the soldering times exceed the upper

limit listed in Table 23–1, consider using a larger tip or

a higher power soldering iron.

5.

Make sure PCB pads and holes are clean prior to

soldering.

6.

Solders with no-clean flux may be used to facilitate

soldering.

7.

Keep the tip of the soldering iron clean and free from

resin. Apply a small amount of solder directly to the

tip of the iron. This process is known as tinning.

8.

Be careful not to jar the module or PCB while the

solder is cooling. This could result in a cold solder

joint, a void in the barrel, or a cracked joint.

9.

If it is necessary to re-solder a joint, remove all

existing solder from the pad and pin prior to

reapplying solder.

10. Use of a soldering gun is not recommended for

soldering Vicor modules.

11. It is not recommended that Maxi, Mini, Micro module

pins be trimmed under any circumstances.

12. The caps of the InMate socket are designed to repel

solder. It is normal for this surface to be free of solder.

As a procedural benchmark, given a 750°F (400°C)

temperature on a 60 W iron with a 0.19 in (3 mm) tip,

approximate times to solder a Vicor power module to a

0.062 (1,5 mm) thick PCB board with an appropriately

sized copper trace would be in the range of Table 14–1.

Again, please note that soldering for significantly longer

periods of time than the time listed above could result in

damage to the module. The time listed in Table 23–1 should

not be used without verifying that the times will produce

a quality soldering joint as defined in the previous sections.

Wave Soldering. Vicor modules achieve an adequate

solder connection on a wave soldering machine with

conveyor speeds from three to seven feet per minute. As

with hand soldering, times and parameters vary with the

properties of the PCB and copper traces. As a standard

benchmark the parameters below may be used. As with

hand-soldered boards, the results should be examined to

ensure a quality soldering joint and a sound process.

Wave Soldering Profile.

1. Bottom-side preheaters: Zone 1: 650°F (343°C),

Zone 2: 750°F ( 398°C)

2. Top-side preheaters: 203 – 248°F (95 – 120°C)

3. Wave temperature: 500°F (260°C)

4. Wave type: 4.25 in (107,9 mm) standard laminar wave

Preheating of the PCB is generally required for wave

soldering operations to ensure adequate wetting of the

solder to the PCB. The recommended temperature for PCB

topside is 203 – 248°F (95 – 120°C) prior to the molten

wave. Thick, multilayer PCBs should be heated toward the

upper limit of this range, while simple two-layer PCBs

should be heated to the lower limit. These parameters are

consistent with generally accepted requirements for

circuit-card assembly.

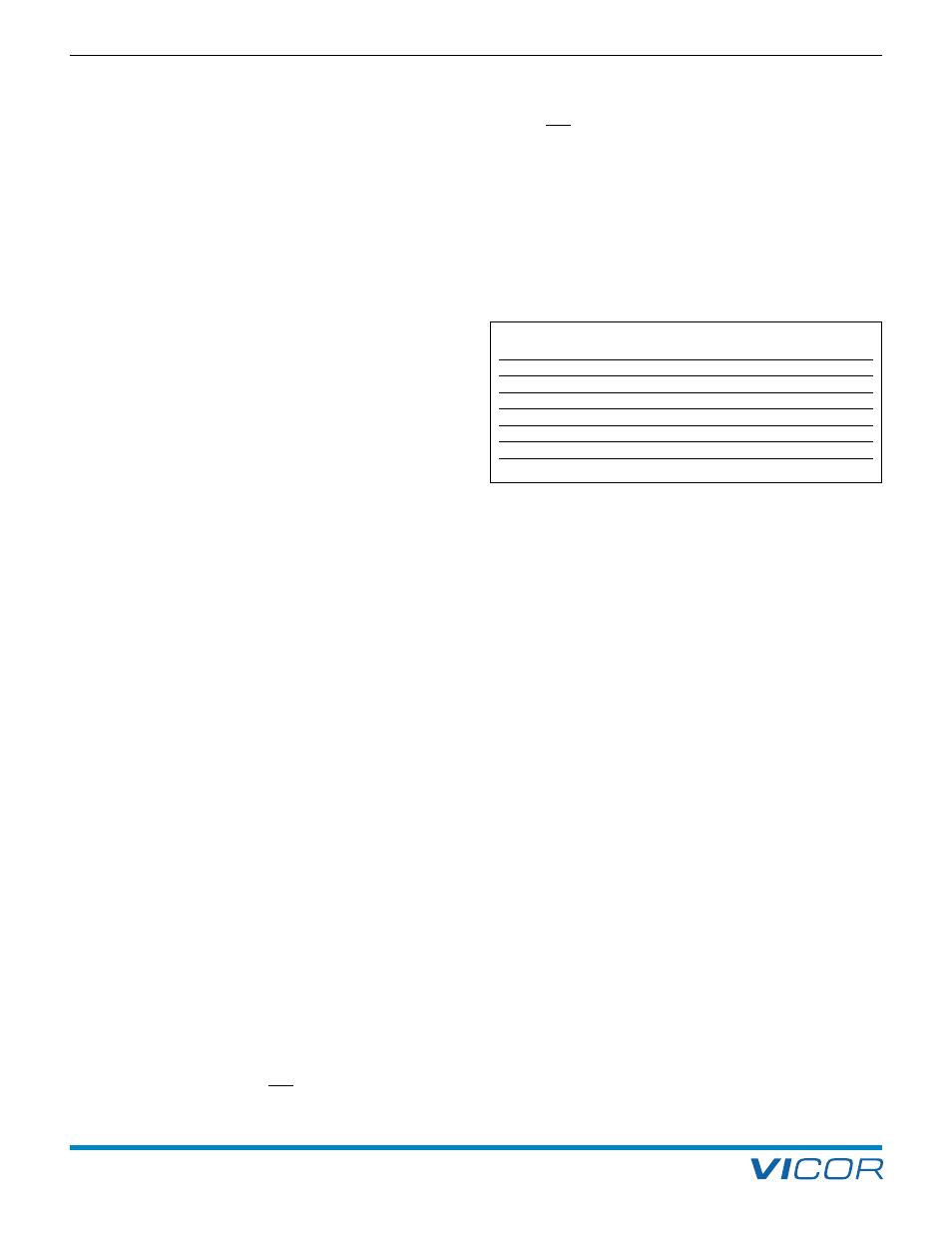

Converter Family

Pin Type

Soldering

Time (range)

VI-200 / VI-J00

Signal

3 – 5 seconds

VI-200

Power

5 – 8 seconds

VI-J00

Power

4 – 7 seconds

Maxi / Mini / Micro

Signal

3 – 5 seconds

Maxi

Power

5 – 8 seconds

Mini

Power

4 – 7 seconds

Micro

Power

3 – 5 seconds

Table 23–1 — Recommended pin soldering times for Vicor modules