Thermal and module mounting considerations – Vicor VI-J00 Family DC-DC Converters and Configurable Power Supplies User Manual

Page 63

Design Guide & Applications Manual

For VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

VI-200 and VI-J00 Family Design Guide

Rev 3.5

vicorpower.com

Page 62 of 98

Apps. Eng. 800 927.9474

800 735.6200

CONVECTION

Convective heat transfer into air is a common method for

cooling Vicor converters. “Free” or “natural” convection

refers to heat transfer from a dissipative surface into a

cooler surrounding mass of otherwise still air; forced

convection refers to heat transfer into a moving air stream.

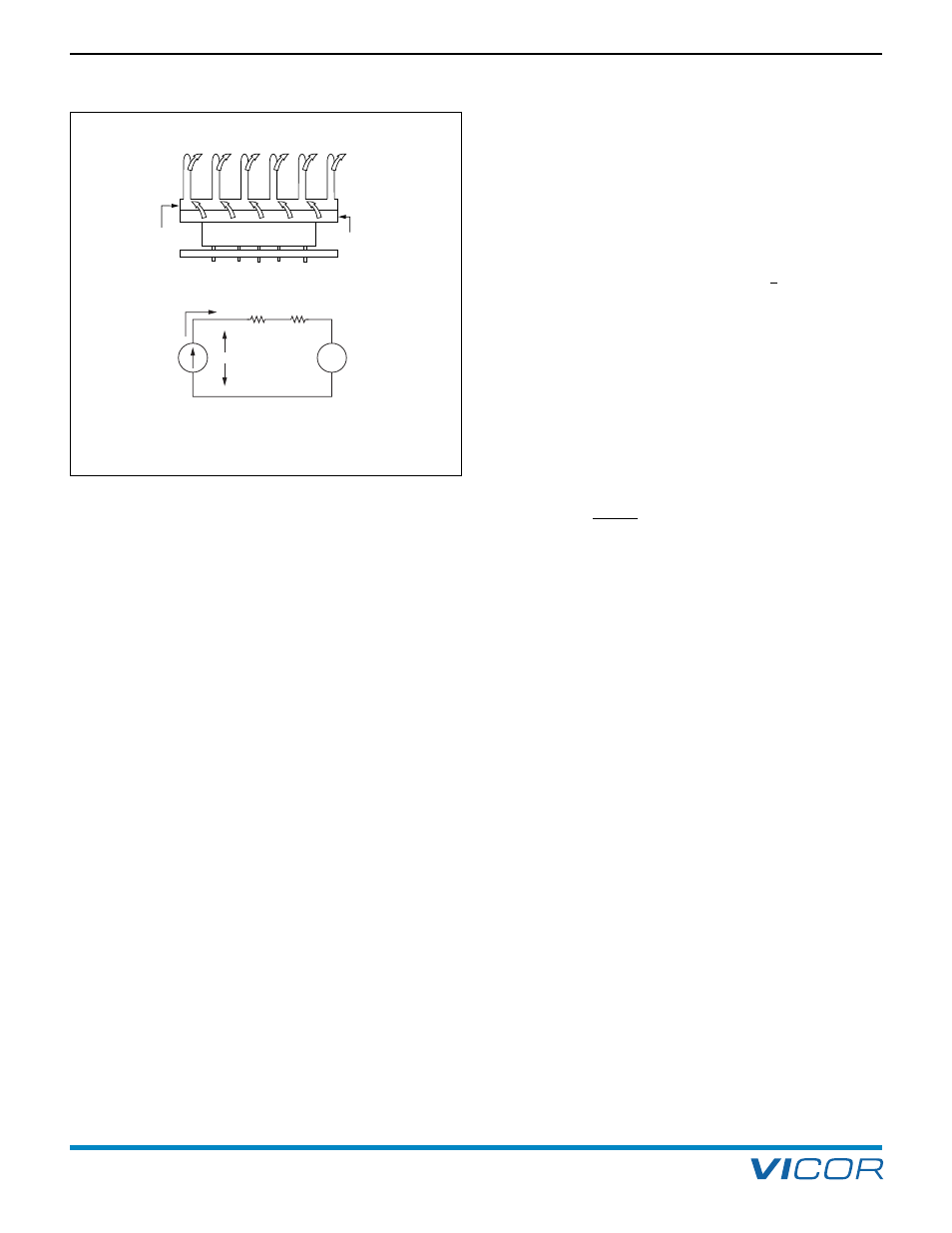

The convection cooling model is shown in Figure 20-4.

Baseplate temperature depends on the temperature of the

air, total dissipated power and the values of two thermal

resistances; the thermal resistance of the surface interface

between the baseplate and the heat sink, and the heat

sink-to-air thermal resistance. Surface interface resistance

can be minimized as discussed under Conduction. The

heat sink-to-air resistance is dependent on a variety of

factors including heat sink material and geometry, air

temperature, air density and air flow rate. Fortunately,

thermal resistance data is available for a very wide range

of standard heat sinks for use in both free and forced

convection applications. The following sections will

provide guidelines for both free and forced convection

cooling of Vicor converters and configurables.

FREE CONVECTION

The benefits of free convection include low cost of

implementation, no need for fans, and the inherent

reliability of the cooling process. Compared to forced air

cooling, however, free convection will require more heat

sink volume to achieve an equivalent baseplate temperature.

To select a suitable heat sink for free convection cooling,

follow these steps:

1. Determine the power to be dissipated by the heat sink.

This should be based upon converter efficiency and

worst-case converter power output using the formula

given in the section on Module Efficiency and Dissipated

Power. (Figures 20–1a and 20–1b)

Power Dissipated = Power Output X

(

1

– 1

)

n

2. Estimate or experimentally determine the surface

interface thermal resistance. Use of thermal compound

or a thermal pad is recommended to minimize this

resistance. An estimate of 0.2˚C / Watt should provide

an adequate safety margin.

3. Referencing Figure 20–4, we can derive the following

formula for heat sink-to-air thermal resistance:

θ

sa

=

(

T

b

– T

a

)

–

θ

bs

P

diss

T

a

= Worst case anticipated operating ambient

air temperature.

θ

bs

= Surface interface thermal resistance, from Step 2.

P

diss

= Worst-case power dissipation, from Step 1.

T

b

= Baseplate temperature.

Start with a value of Tb = 85˚C (or 100˚C, VI-J00) to

determine the maximum acceptable heat sink-to-air

thermal resistance.

4. Select several heat sinks that appear physically

acceptable for the application. Using data provided,

obtain values for their free convection thermal

resistance, preferably at worst-case ambient

temperature, Ta. If values obtained are less than the

value calculated in Step 3, go on to Step 5. If the

values are greater, then either a physically larger heat

sink will be required or a different cooling method will

need to be used (i.e., forced air, etc.).

5. Select the heat sink with the lowest available thermal

resistance consistent with space and cost limits. Keep

in mind that small reductions in baseplate temperature

produce dramatic improvements in MTBF.

6. Baseplate temperature can be estimated by using the

following formula:

T

b

= T

a

+ P

diss

x (

θ

bs

+

θ

sa

)

7. Test to verify that performance is in line with expectations.

20. Thermal and Module Mounting Considerations

Figure 20–4 — Heat sink thermal considerations

(+)

Tb

(–)

Pdiss

Power

Dissipated

by Converter

(Watts)

Tb = Baseplate Temperature

bs = Baseplate – Heatsink Interface Resistance

sa = Heatsink-to-Air Thermal Resistance

Tb = Ta + ( bs + sa) x Pdiss

Ambient Air

Temperature

+

Ta

–

bs

sa

θ

θ

θ

θ

θ

θ

Surrounding Air Temperature (Ta)

Heat Flow

Heatsink

Baseplate