Sect. 19, Ac input power system (pfc flatpac) – Vicor VI-J00 Family DC-DC Converters and Configurable Power Supplies User Manual

Page 59

Design Guide & Applications Manual

For VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

VI-200 and VI-J00 Family Design Guide

Rev 3.5

vicorpower.com

Page 58 of 98

Apps. Eng. 800 927.9474

800 735.6200

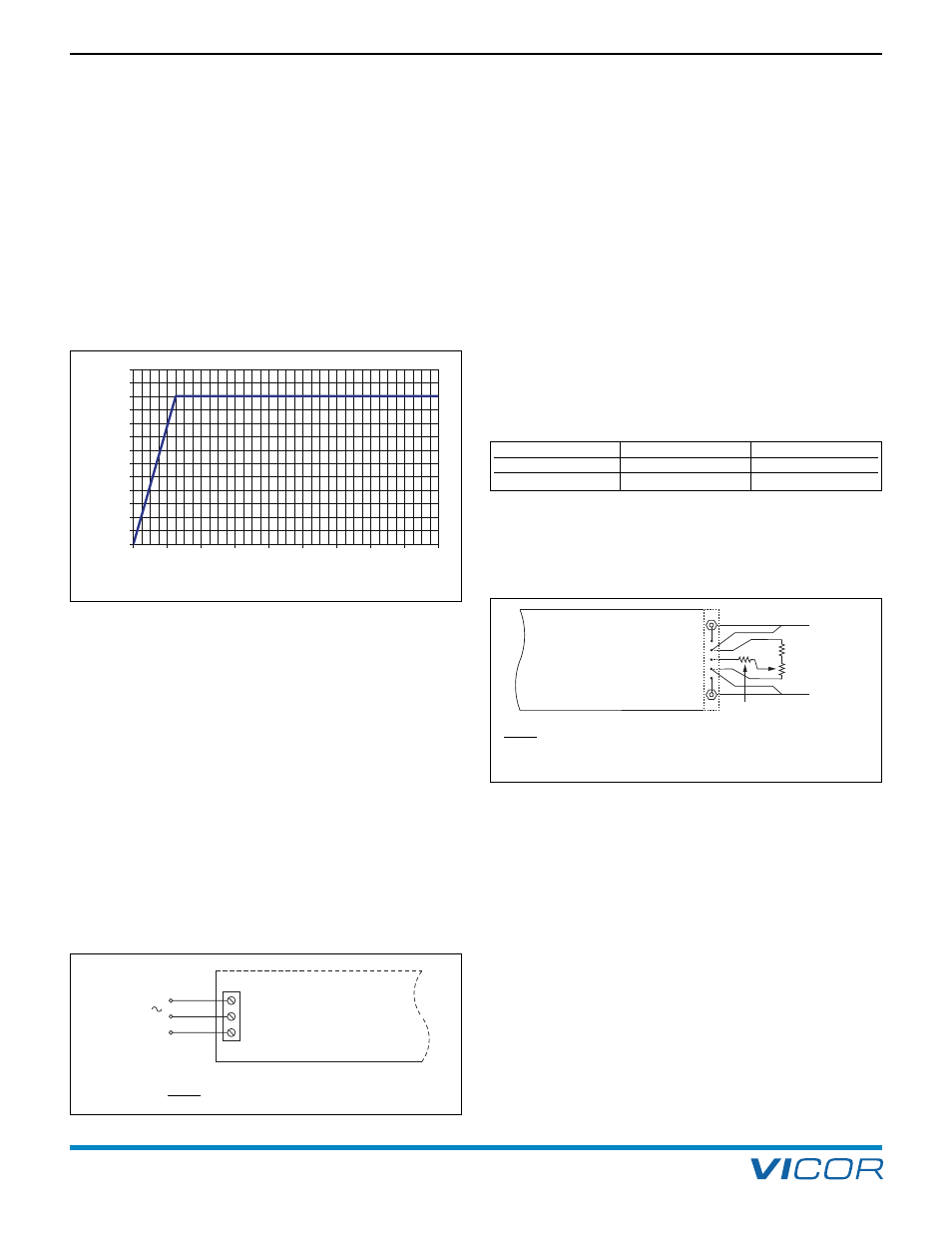

19. AC Input Power System (PFC FlatPAC)

OVERVIEW - PFC FLATPAC

The PFC FlatPAC consists of a universal input (85-264 Vac)

AC front end and one Maxi DC-DC converter in an

integrated mechanical assembly providing up to 575 W of

power. Using Vicor’s Harmonic Attenuator Module (HAM)

and integrated filtering, the PFC FlatPAC meets

EN61000-3-2 harmonic current limits and 0.99 power

factor. The internal filtering provides compliance to

EN55022-A conducted EMI.

The PFC FlatPAC will accept an input voltage of 85-264 Vac,

derate power at 9 W/Vrms as shown in Figure 19–1.

CIRCUIT OPERATION

AC line voltage is applied via an agency-approved terminal

block providing AC mains (L1, L2/N and GND). Current in

the L1 lead is applied to a 15 A / 250 V internal fuse This

current is interrupted only in the event of a catastrophic

failure of a main power component internal to the PFC

FlatPAC.

The input current beyond the fuse is passed through an

EMC filter designed to meet conducted noise limits of

FCC Part 15 EN55022 Class A. At start-up, AC inrush

current is limited by the HAM’s internal circuitry prior to

being passed to the main energy storage capacitors.

The DC-DC converter is held off until the internal DC bus

potential has settled to full operating level. The converter

is then enabled.

Fusing. The PFC FlatPAC’s internal fuse is not

user-replaceable.

Grounding. To satisfy IEC950 Class I grounding

requirements, connect a ground lead to the terminal

marked (GND). Use 2.5 mm

2

/ #14 AWG wire.

Input Voltage Connections. Connect the line voltage to

L1 (hot) and L2N (neutral). Use #14AWG input wire.

Recommended connector screw torque is 5 to 7 in-lbs

(0.5 to 0.8 N-m). Recommended strip length is 8 mm.

Refer to Figure 19–2.

Output Wire Gauge. Use the output wire gauge that

corresponds to the output current of your FlatPAC unit,

below: Do not loosen bottom nut. Long cable runs, or

wires in large bundles will require heavier cable to avoid

excessive voltage drops or overheating.

Output Voltage Trimming. The Maxi converters used in

the PFC FlatPAC have a wide trim range of +10% to -

90%. See the Maxi, Mini, Micro design guide for details.

Operating Temperature. Do not allow the PFC FlatPAC

to exceed its maximum operating temperature, which is

reached when the heat sink is 85°C. (Full power can be

delivered up to this temperature.) Heat sink temperature is

a function of the output power and voltage of the supply,

ambient temperature, and airflow across the heat sink.

Always use worst-case conditions when calculating

operating temperature.

AC Mains

Earth Ground

L1

L2/N

GND

Figure 19–2 — AC mains connections

NOTE: Product is internally fused.

+Out

+Sense

Trim

–Sense

–Out

+ V

OUT

V

OUT

RTN

R2

R1

10K

NOTE: +Sense and –Sense must be connected locally or

remotely (shown). See calculator for output voltage trimming

at vicorpower.com

Figure 19–3 — Output sense and trim

Vin (Vrms)

P

o

u

t

(W

)

340

360

380

400

420

440

460

480

500

520

540

560

580

600

85

105

125

145

165

185

205

225

245

265

Figure 19–1 — PFC FlatPAC output power vs. input voltage

100 A–160 A : #2 AWG 30 A–50 A : #8 AWG

10 A–15 A : #14 AWG

75 A–100 A : #4 AWG

20 A–30 A : #10 AWG

6 A–10 A : #16 AWG

50 A–75 A : #6 AWG

15 A–20 A : #12 AWG

0 A–6 A : #18 AWG

Table 19–1