Sect. 23, Tin lead pins – Vicor VI-J00 Family DC-DC Converters and Configurable Power Supplies User Manual

Page 84

Design Guide & Applications Manual

For VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

VI-200 and VI-J00 Family Design Guide

Rev 3.5

vicorpower.com

Page 83 of 98

Apps. Eng. 800 927.9474

800 735.6200

23. Recommended Soldering Methods,

Tin Lead Pins, and InMate Sockets

The following chapters contain soldering information for

the following Vicor product families; Maxi, Mini, Micro;

VI-200, VI-J00; VI BRICK

®

, and similar package filters and

front-ends. This document is intended to provide guidance

in utilizing soldering practices to make high-quality

connections of Vicor power modules to printed circuit

boards. Some care will be taken to outline appropriate

soldering procedures as well as the evaluation of solder

joints in a manner that enables the customer to ensure

that the end application has an optimal connection to the

power module. Common soldering defects will be

examined and direction will be provided for detecting and

handling the common defects.

Vicor’s manufacturing facilities use the IPC-A-610C

standards as a means of establishing quality solder joints.

It is recommended that manufacturing processes using

Vicor modules refer to these same standards, which can

be found, along with supporting documentation, at

ANALYSIS OF A GOOD SOLDER JOINT

The IPC-A-610C standard requires that solder fill at least

75% of the barrel in order to ensure a solid connection.

Ideally, all connections should have a 100% fill. In order to

accomplish this, the solder applied to both the barrel and

the pin must exhibit a process known as wetting. Wetting

occurs when liquid solder on a surface is heated to the

point that it loses a significant amount of latent surface

tension and evenly coats the surface via capillary action

(both cohesion and adhesion).

During the soldering process wetting can be identified by

an even coating of solder on the barrel and pin. In

addition to coating the surface of barrel and pin, the

solder will gather at the intersection of the two and

produce a trailing fillet along each surface. Once wetting

has occurred, then upon solidification it will bond

appropriately to both components, producing a quality

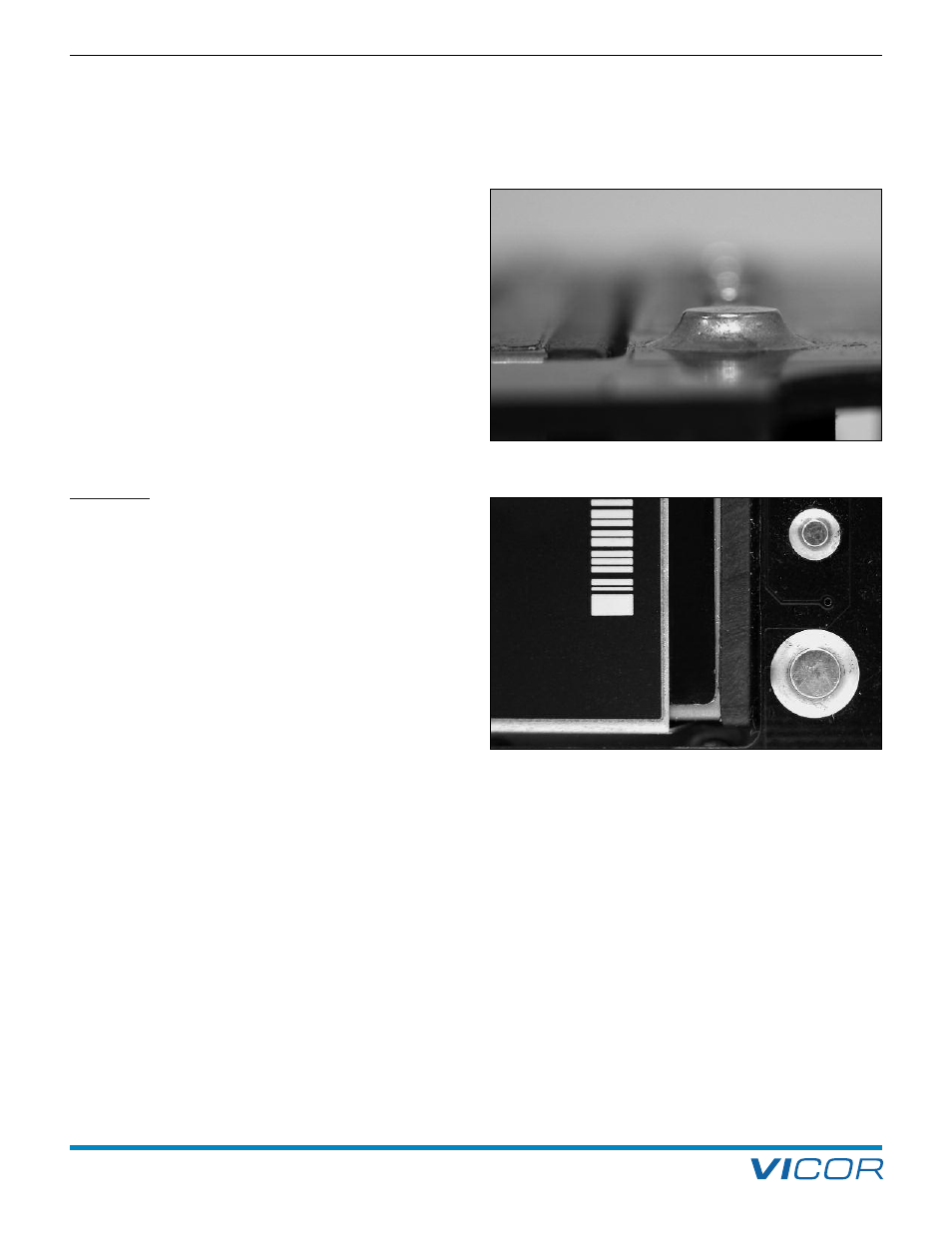

connection. Figure 23–1 shows a side profile of a good

solder joint with a Mini power module. Notice that for

both examples the solder forms a concave meniscus

between pin and barrel. This is an example of a properly

formed fillet and is evidence of good wetting during the

soldering process. The joint between solder and pin as

well as solder and pad should always exhibit a feathered

edge. In Figure 23–1 it can also be seen that the solder

covers a good deal of the surface area of both the pin

and the pad. This is also evidence of good wetting. Notice

also that the solder joint has a smooth surface with a

silver color. This is evidence of good immobilization of the

joint during cooling as well as good cleaning of the board

prior to soldering. All soldering connections should exhibit

similar characteristics regardless of whether they are

soldered by hand or wave soldered.

Figure 23–2 is a top view of the signal and power pin of a

Maxi or Mini module properly soldered to a printed circuit

board. Notice that both the joint and the area around the

joint are clean and free from resin and solder residue. Also

the pad and printed circuit board adjacent to the barrel

are not burnt or discolored and are solidly attached to

each other. In examining a solder joint, be sure that there

is no solder connecting one pad to another. This is known

as a solder bridge and will be discussed further along with

other potential soldering defects.

Figure 23–2 — Maxi / Mini output power pin and Sense pin

Figure 23–1 — Side profile of a Mini module solder joint

OVERVIEW