Thermal and module mounting considerations – Vicor VI-J00 Family DC-DC Converters and Configurable Power Supplies User Manual

Page 62

Design Guide & Applications Manual

For VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

VI-200 and VI-J00 Family Design Guide

Rev 3.5

vicorpower.com

Page 61 of 98

Apps. Eng. 800 927.9474

800 735.6200

Temperature differentials encountered in practical

applications of Vicor converters are never large enough

to cause radiational cooling to be the dominant heat

transfer mechanism. Radiation will account for less than

10% of total heat transfer in the majority of cases. For

these reasons, the presence of radiant cooling is often

assumed to provide safety margins over and above the

dominant cooling mechanism, and detailed consideration

of its effects are neglected. A valid assumption, in most

cases, is that the converter will be warmer than its

surroundings and radiant energy transfer will aid cooling.

In some cases, however, nearby objects (PC boards, power

resistors, etc.) may be much hotter than the converter and

net radiant energy transfer may actually increase the

converter’s temperature.

Surveying the relative positions and estimated temperatures

of converters and surrounding parts is advisable as a means

of anticipating the potential effects of radiant transfer. In

cases where hot components are in close proximity to the

converter, the use of interposing barriers can generally

moderate undesirable radiational heating effects.

CONDUCTION

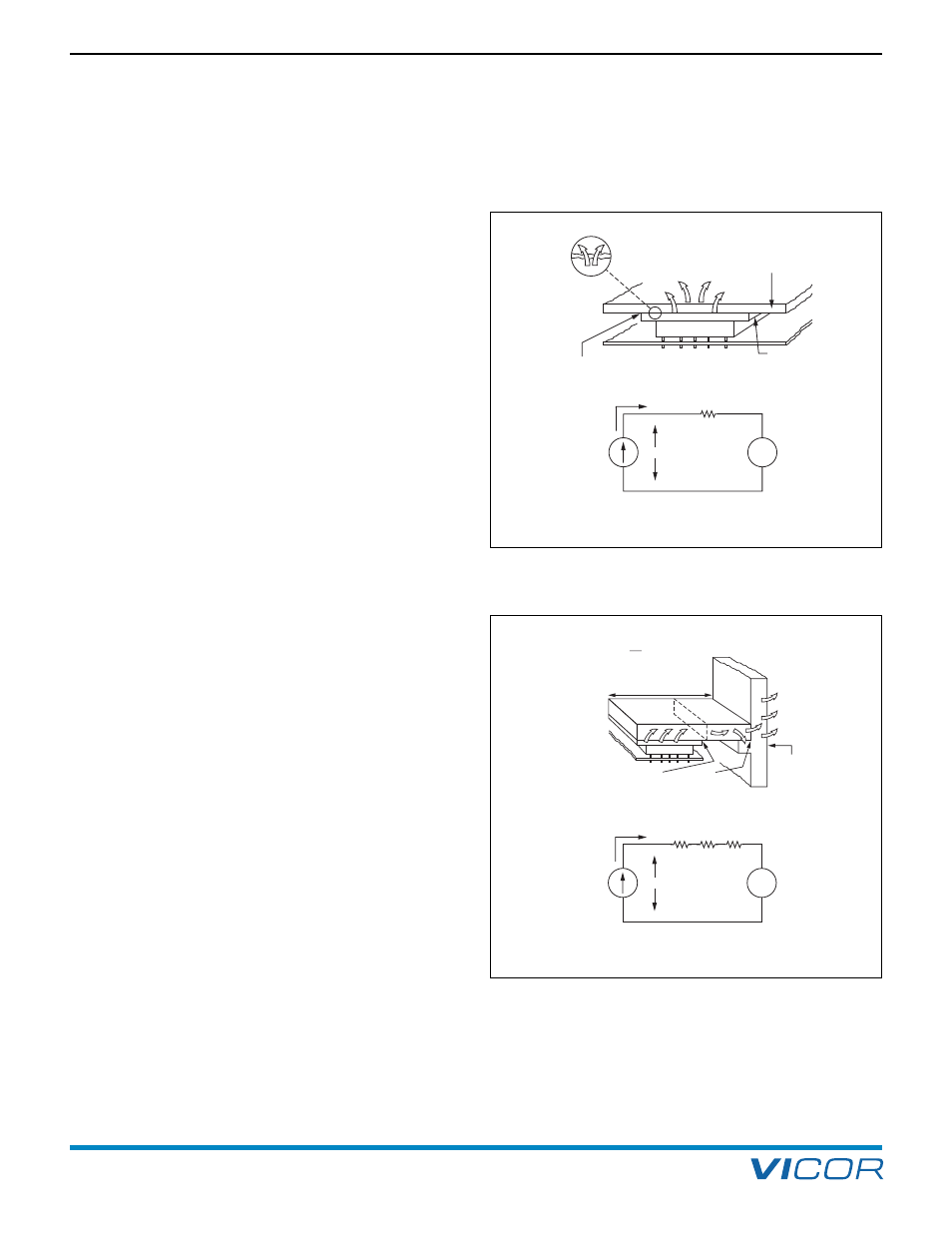

In most applications, heat will be conducted from the

baseplate into an attached heat sink or heat conducting

member. Heat conducted across the interface between the

baseplate and mating member will result in a temperature

drop which must be controlled. As shown in Figure 20–2,

the interface can be modeled as a “thermal resistance” in

series with the dissipated power flow. The baseplate

temperature will be the sum of the temperature rise in the

interface and the temperature of the member to which

the baseplate is attached.

Temperature rise across a surface interface can be

significant if not controlled. The area of the interface

should be as large as possible, and the surface flatness of

the attached member should be within 5 mils. Thermal

compound or a thermal pad should be used to fill surface

irregularities. Thermal resistance across surface interfaces

can be held to under 0.1˚C / Watt with proper measures.

Many applications require that heat be conducted from

the baseplate of the converter to a “remote” dissipative

surface via a thermally conductive member. The resulting

baseplate temperature will be the sum of the temperature

of the dissipative surface, the temperature rise in the heat

conducting member, and the rises across the two surface

interfaces. The thermal resistance of the conductive

member is proportional to its length, and inversely

proportional to both its cross-sectional area and thermal

conductivity (Figure 20–3). Minimizing total temperature

rise is dependent on controlling interface resistance, as

described above, and controlling the thermal resistance of

the transfer member through appropriate material

selection and dimensioning.

20. Thermal and Module Mounting Considerations

Baseplate

Heat Flow

Mating Member

at Temperature = Ts

Surface Irregularities

Produce Temperature

Drop in the Interface

θ

bs = Interface Thermal Resistance (°C/Watt)

(+)

Tb

(–)

Pdiss

Power

Dissipated

by Converter

(Watts)

Tb = Baseplate Temperature

= Ts + Pdiss x bs

Temperature

of Mating

Surface (°C)

+

Ts

–

bs

θ

θ

Figure 20–2 — Baseplate thermal considerations

Figure 20–3 — Interface thermal considerations

Thermal Resistance of Conducting Member ( m)

m =

KA

K = Thermal Conductivity

A = Cross Sectional Area

L = Length

L

bm

Interface

Resistance

ms

Interface

Resistance

Cooling

Surface at

Temperature

= Ts

L

A

θ

θ

θ

θ

(+)

Tb

(–)

Pdiss

Power

Dissipated

by Converter

(Watts)

Tb = Baseplate Temperature

= Ts + ( bm + m + ms) x Pdiss

Temperature

of Cooling

Surface (°C)

+

Ts

–

bm

ms

m

θ

θ

θ

θ

θ

θ