Dc input power system (compac / mi-compac family) – Vicor VI-J00 Family DC-DC Converters and Configurable Power Supplies User Manual

Page 54

Design Guide & Applications Manual

For VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

VI-200 and VI-J00 Family Design Guide

Rev 3.5

vicorpower.com

Page 53 of 98

Apps. Eng. 800 927.9474

800 735.6200

RECOMMENDED INPUT LINE FUSING

The ComPAC must be fused externally. The table below

lists the fuse ratings for one, two and three-up units

(maximum output 200, 400 and 600 W).

RECOMMENDED INPUT WIRING AND TORQUE

RECOMMENDED OUTPUT WIRING

Use the output wire gauge that corresponds to the output

current of the ComPAC unit:

Long cable runs, or wires in large bundles will require

heavier cable to avoid excessive voltage drops or overheating.

GROUNDING

For safe operation, the ComPAC unit must be grounded.

Connect a ground lead to the terminal marked (GND). Use

the same wire gauge as that specified for your ComPAC

unit’s input voltage connections.

MASTER DISABLE

The ComPAC incorporates an optically isolated Master

Disable input which will shut down the ComPAC output

when a current is driven through the disable terminals.

DISABLE CURRENT

• 4 mA DC minimum for 1-up ComPAC

• 8 mA DC minimum for 2-up ComPAC

• 12 mA DC minimum for 3-up ComPAC

TRIMMING

The nominal output voltage of the ComPAC can be

adjusted from 110% to 50% of nominal voltage. Refer to

, Section 5, for external resistor

values. DO NOT trim the outputs higher than 110% of

their nominal output power (output overvoltage protection

may trigger). When the output is trimmed up, do not

exceed its maximum rated output power.

NOTE: 10 V, 12 V, and 15 V outputs, standard trim

range ±10%, 3.3 V output trim range 2.20 to 3.63 V.

REMOTE SENSING

+SENSE and –SENSE must be connected locally or remotely.

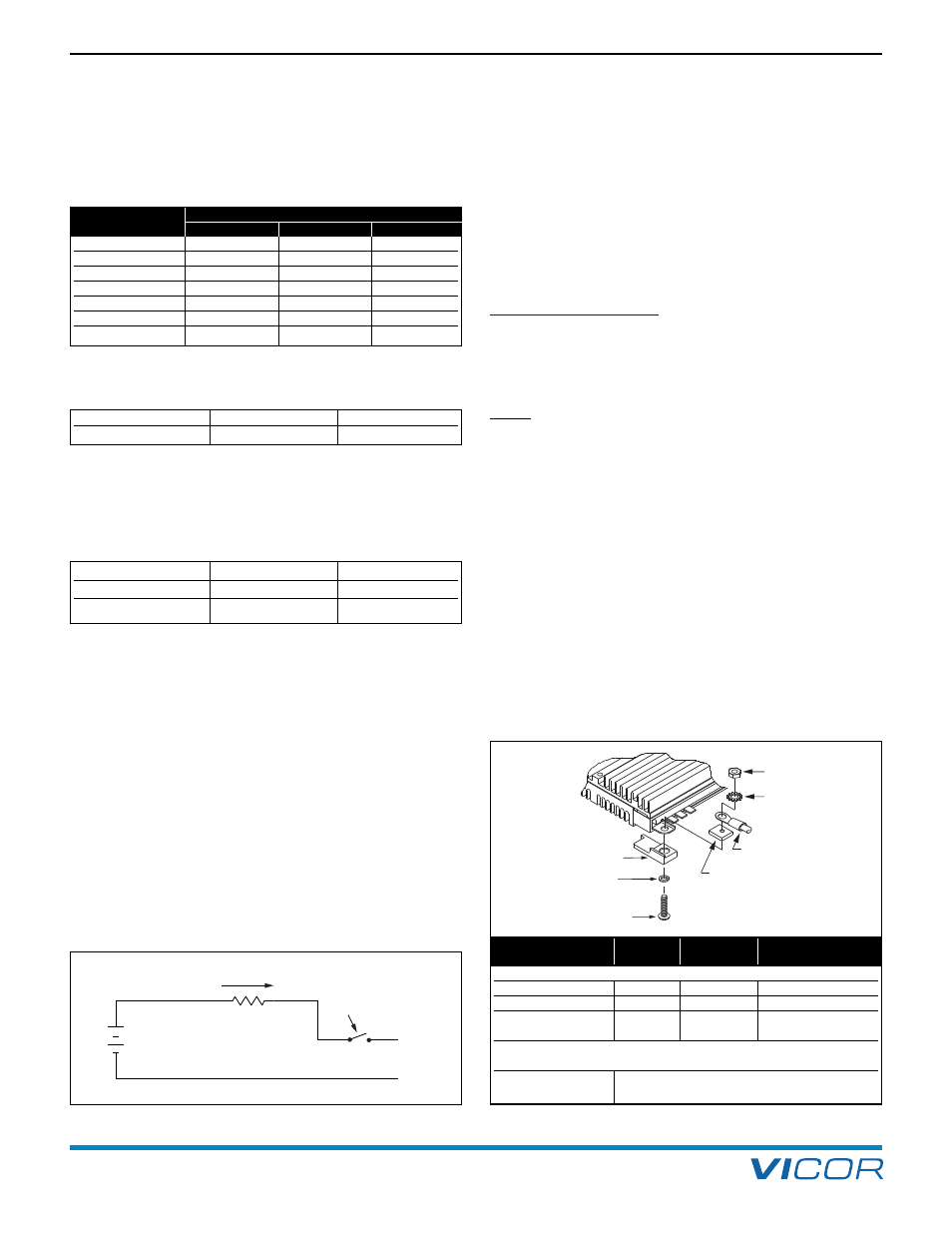

OUTPUT TERMINAL CONNECTIONS

A hardware kit with parts for output terminal connections is

provided with each ComPAC unit. The following drawing

shows the assembly of those parts for the proper

connection of metal power terminals. Assembly for PCB

power terminals is the same except that they do not require

an external tooth lockwasher. See Figure 17–2 for the

recommended torque level for each stud size.

17. DC Input Power System (ComPAC / MI-ComPAC Family)

20 mA Max.

Disable

DIS+

DIS–

+

V

Figure 17–1 — ComPAC module disable

EXTERNAL TOOTH

LOCKWASHER

#10 TERMINAL

RETAINING NUT

#10 NUT PLATE

USER OUTPUT

TERMINALS

#10 BRASS STUD

HELICAL

LOCKWASHER

(FITS WITHIN

OPENING PROVIDED)

TERMINAL COVER

NEGATIVE

Figure 17–2 — Output terminal connections

24 V

10 A / 32 V

20 A / 32 V

30 A / 32 V

24 V (wide)

12 A / 32 V

20 A / 32 V

30 A / 32 V

28 V (military)

10 A / 250 V

20 A / 250 V

30 A / 125 V

48 V

8 A / 60 V

15 A / 60 V

25 A / 60 V

48 V (wide)

6 A / 100 V

15 A / 100 V

25 A / 100 V

270 V (military)

2 A / 250 V

4 A / 250 V

6 A / 250 V

300 V

2 A / 250 V

4 A /250 V

6 A / 250 V

Nominal

Fuse Rating

Input Voltage

1-Up

2-Up

3-Up

1-Up

#16 AWG

10 in-lb

2-Up

#14 AWG

15 in-lb

105 A – 160 A: #4 26 A – 40 A: #10

7 A – 10 A: #16

66 A – 104 A: #6 16 A – 25 A: #12

4 A – 6 A: #18

41 A – 65 A: #8 11 A – 15 A: #14

0 A – 3 A: #20

–OUT, +OUT Terminals

LC, PC, RC Series

PCB

8-32 UNC

10 in-lbs (1.1 N-m)

MC and NC Series

Metal

10-32 UNC

15 in-lbs (1. 7 N-m)

QC Series

PCB

8-32 UNC

10 in-lbs (1.1 N-m)

Metal

10-32 UNC

15 in-lbs (1.7 N-m)

+ / – SENSE, TRIM Terminals

All Models

Sized to accept Amp Faston

©

insulated

receptacle #2-520184-2.

Terminal and

Terminal

Stud

Recommended

Product Model

Style

Size

Torque