Thermal and module mounting considerations – Vicor VI-J00 Family DC-DC Converters and Configurable Power Supplies User Manual

Page 66

Design Guide & Applications Manual

For VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

VI-200 and VI-J00 Family Design Guide

Rev 3.5

vicorpower.com

Page 65 of 98

Apps. Eng. 800 927.9474

800 735.6200

VI-200

Part #30089 Part #30775 Part #30090 Part #30780 Part #30193 Part #30194

FinMod

FinMod

MI-200

Baseplate

0.9"L Fins

[a]

0.7"L Fins 0.9"T Fins

[b]

1.45"L Fins

0.7"T Fins

0.4"T Fins

SlimMod

–F1 / –F3

–F2 / –F4

θbs = 0.2

(22,86 mm) (17,78 mm) (22,86 mm) (36,83 mm) (17,78 mm) (10,16 mm)

θsa

θsa

θsa

θsa

θsa

θsa

θsa

θsa

θsa

θsa

Free Air

5.10

3.40

4.08

2.70

2.60

3.15

3.80

5.40

5.00

3.70

200 LFM

2.80

1.50

1.80

1.10

1.00

1.28

1.55

3.20

2.40

1.80

400 LFM

1.80

1.00

1.20

0.80

0.60

0.93

1.13

2.20

1.50

1.20

600 LFM

1.40

0.80

0.96

0.60

0.50

0.70

0.84

1.60

1.10

0.90

800 LFM

1.20

0.60

0.72

0.50

0.40

0.58

0.70

1.30

0.90

0.70

1,000 LFM

1.00

0.50

0.60

0.40

0.30

0.47

0.56

1.20

0.80

0.60

VI-J00

Part #30191

Part #30771

Part #30140

FinMod

FinMod

MI-J00

Baseplate

0.9" L Fins

0.9" T Fins

0.4" T Fins

SlimMod

–F1 / –F3

–F2 / –F4

θbs = 0.4

(22,86 mm)

(22,86 mm)

(10,16 mm)

θsa

θsa

θsa

θsa

θsa

θsa

θsa

Free Air (H)

8.10

4.20

4.00

5.63

8.50

8.00

7.00

Free Air (V)

7.60

4.00

3.90

5.49

8.40

7.30

6.70

200 LFM

5.10

1.60

1.60

2.25

5.50

5.00

2.70

400 LFM

2.70

1.30

1.30

1.83

3.60

2.50

1.50

600 LFM

2.30

0.90

0.90

1.27

2.90

2.10

1.20

800 LFM

1.70

0.70

0.70

0.99

2.30

1.30

0.80

1,000 LFM

1.40

0.60

0.60

0.84

2.00

1.10

0.70

Configurables

FlatPAC

[c]

ComPAC

[c]

MegaMod

[c]

(also applies to MI-ComPAC

1-Up

2-Up

3-Up

1-Up

2-Up

3-Up

1-Up

2-Up

3-Up

and MI-MegaMod)

θbm

θbm

θbm

θbm

θbm

θbm

θbm

θbm

θbm

0.1

0.05

0.03

0.1

0.05

0.03

0.1

0.05

0.03

θsa

θsa

θsa

θsa

θsa

θsa

θsa

θsa

θsa

Free Air

2.1

1.3

1.0

3.6

1.7

1.4

4.4

2.1

1.7

50 LFM

1.5

1.1

0.9

2.7

1.4

1.3

3.3

1.7

1.6

100 LFM

1.2

0.9

0.7

2.3

1.3

1.1

2.8

1.6

1.3

250 LFM

0.7

0.5

0.4

1.6

1.0

0.8

2.0

1.2

1.0

500 LFM

0.4

0.3

0.3

1.2

0.7

0.6

1.5

0.9

0.7

750 LFM

0.3

0.2

0.2

0.9

0.5

0.5

1.1

0.6

0.6

1,000 LFM

0.2

0.2

0.2

0.8

0.4

0.4

1.0

0.5

0.5

[a]

Longitudinal fins

[b]

Transverse fins

[c]

Assumes uniform loading of two and three output units.

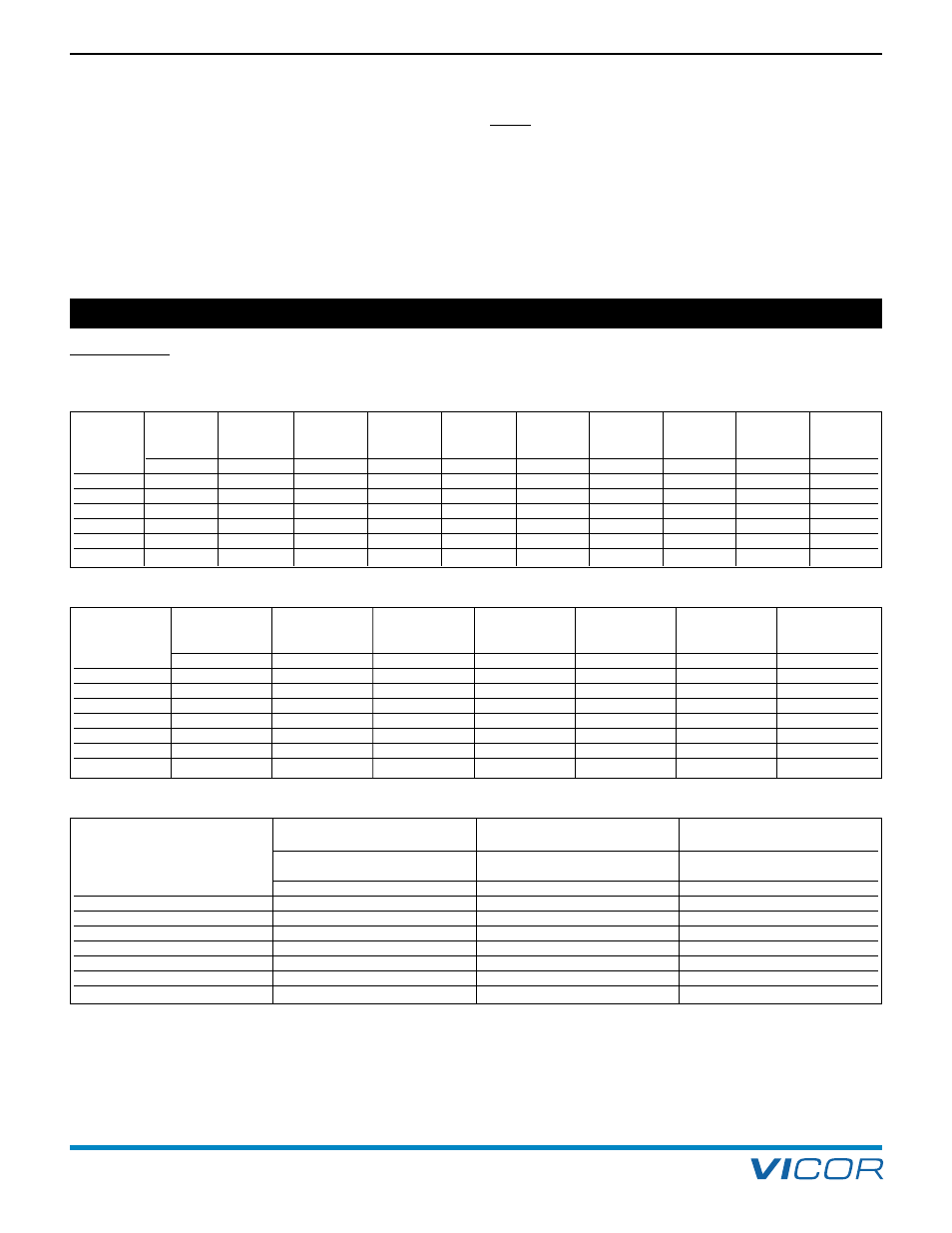

Thermal Impedance Table (°C/W)

improvement in baseplate temperature results in

significant improvement in MTBF. If you are paying for

a fan, you may as well leverage it for all that it is worth.

3. Steps 5 through 7 in the Free Convection section will

complete the heat sink selection process. Select the fan

/ heat sink combination with the lowest thermal resistance

consistent with cost and space constraints, calculate the

estimated baseplate temperature and test to verify.

NOTE: The values of

θsa incorporating add-on or

integral heat sinks include the baseplate-to-heat sink

thermal resistance

θba. When using heat sinks from

other sources, the thermal impedance baseplate-to-air

will be the sum of the thermal impedance heat sink-

to-air specified by the heat sink manufacturer and the

baseplate-to-heat sink impedance from the following

Thermal Impedance Charts that follow.

20. Thermal and Module Mounting Considerations

Table 20–2a — Thermal impedance for VI-200 / MI-200

Table 20–2b — Thermal impedance for VI-J00/MI-J00

Table 20–2c — Thermal impedance for FlatPAC, ComPAC / MI-ComPAC and MegaMod /MI-MegaMod Families

TABLE USAGE: The forced convection thermal impedance data shown in the tables below assumes airflow

through the heat sink fins. Actual airflow through the fins should be verified. For purposes of heat sink

calculation, assume efficiencies of 81% for 5 V outputs and 85% for 12 V and above.