5 tuning the control loop, Section 6.5, tuning the, D value. see – INFICON IQM-233 Thin Film Deposition Controller PCI-Express Card Operating Manual User Manual

Page 91

6 - 5

PN

07

4-

58

4-

P1

A

IQM-233 Operating Manual

6.5 Tuning the Control Loop

The function of the control loop parameters is to match the instrument’s reaction to

an error (between the measured deposition rate and the desired rate) to the time

related characteristics of the deposition source and its power supply. There are

three adjustable parameters; P (proportional), I (integral) and D (derivative) used

to accomplish this. It is convenient to think of sources as falling into two categories:

"fast" or "slow." The tuning parameters are affected by source level, rate, sweep

range or beam density, Tooling and source condition.

The P parameter is the proportional term that sets the gain of the control loop. Enter

a higher value for a more responsive (but potentially unstable) control loop and a

lower value for the less responsive control loop.

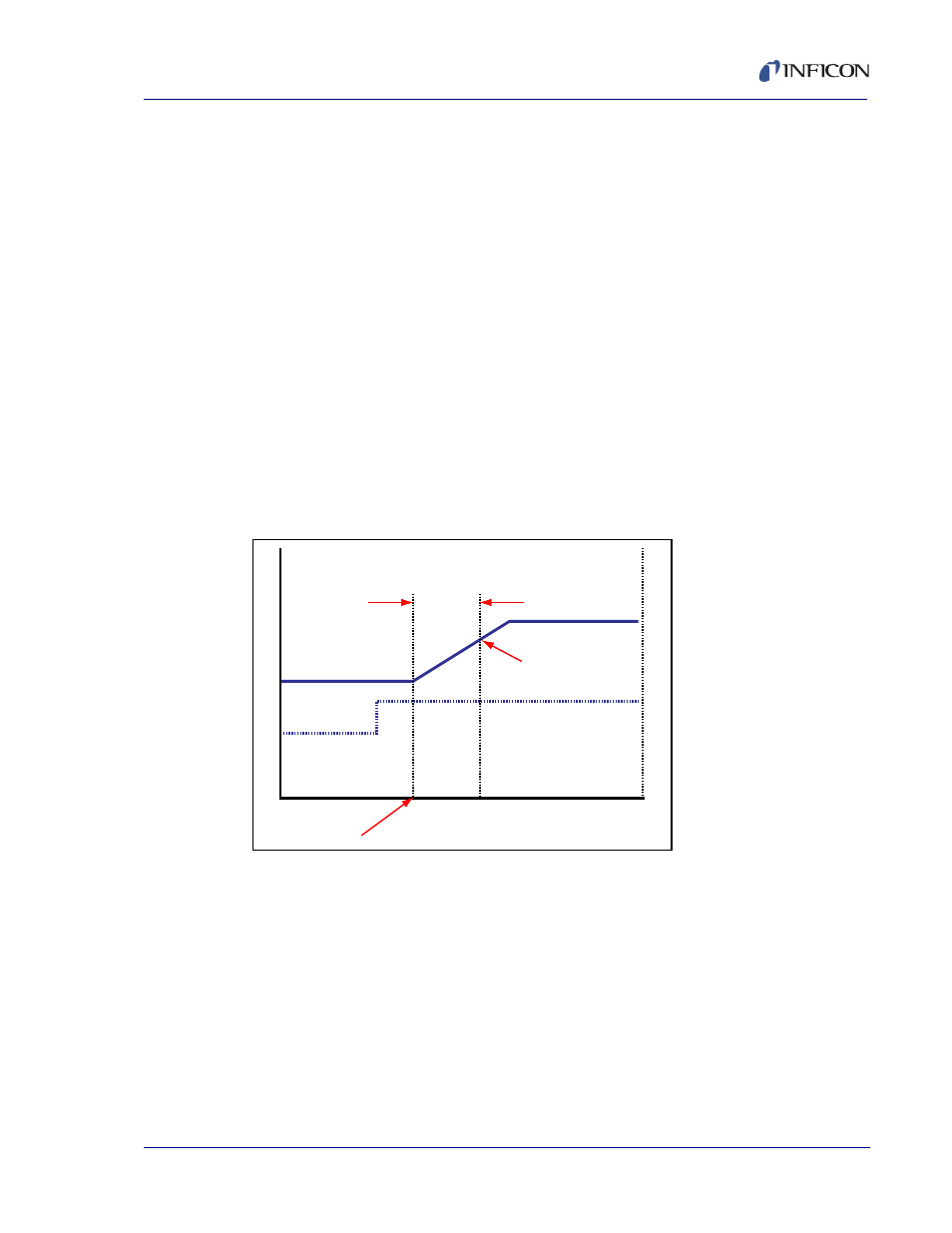

The I parameter is defined as the integral term that inversely sets the set point

correction gain (a small number causes more error correction). It can be estimated

as twice the time for the rate to go from 1/3 to 2/3 of the desired rate (see

). It instructs the controller on how much attention to pay to the schedule of the

rate profile.

Figure 6-1 Determining the I value

The D parameter is equivalent to the system Dead Time and is used to compensate

for slow responding sources such as boats and induction heated sources. This

value can be estimated from the time difference between a change in % power and

the start of an actual change in rate (see

.) The D parameter instructs the

controller on how much attention to pay to the Rate Deviation error. A value of zero

tells the controller to ignore the Rate Deviation error. A large value tells the

controller that the source is slow and it is going to be harder to get it going and

harder to stop it. Therefore, if the rate starts to fall off, power increases, or if the

target rate is quickly approaching, power decreases.

Measurement rate noise may

R

A

T

E

P

O

W

E

R

TIME CONSTANT

TIME

RATE INCREASE

Power

Rate

63% POINT

0

2/3 Rate Point

Rate Change

Desired Rate

Time from 1/3 to 2/3

1/3 Rate