INFICON IQM-233 Thin Film Deposition Controller PCI-Express Card Operating Manual User Manual

Page 79

5 - 5

PN

07

4-

58

4-

P1

A

IQM-233 Operating Manual

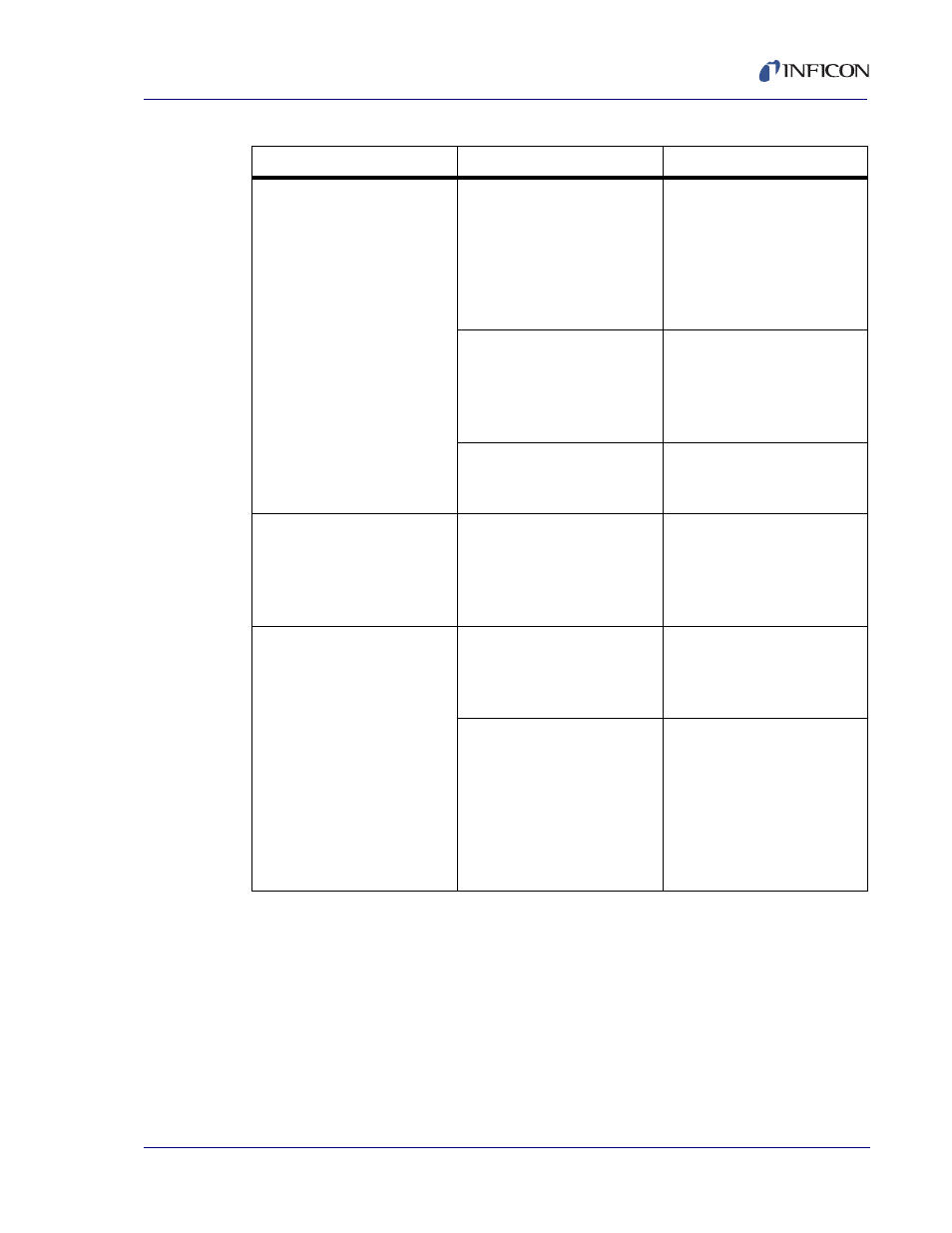

Freq (Hz) displays Fail

during deposition before

“normal” life of crystal is

exceeded.

Crystal is being hit by small

droplets of molten material

from the evaporation source.

Use a shutter to shield the

sensor during source

conditioning.

Move the crystal farther away

(at least 25.4 cm (10 in.))

from the source.

Damaged crystal or

deposited material is causing

stress to crystal.

Replace the crystal.

Use an Alloy crystal if

appropriate for deposited

material.

Material build-up on crystal

holder is partially masking

the crystal surface.

Clean or replace the crystal

holder.

Freq (Hz) displays Fail

during deposition before

“normal” life of crystal is

exceeded.

Shutter is partially

obstructing deposition flux or

sensor is poorly positioned,

causing uneven distribution

of material on crystal.

Visually check crystal for an

uneven coating, and if

present, correct shutter or

sensor positioning problem.

Freq (Hz) displays Fail

when vacuum chamber is

opened to air.

Crystal was near the end of

its life; opening to air causes

film oxidation, which

increases film stress.

Replace the crystal.

Excessive moisture

accumulation on the crystal.

Avoid condensation by

turning off cooling water to

sensor before opening the

vacuum chamber to air, and

then flow heated water above

the room’s dew point through

the sensor when the

chamber is open.

Table 5-1 Symptom/Cause/Remedy Chart (continued)

SYMPTOM

CAUSE

REMEDY