10 forks, Forks – SkyTrak 6036 Service Manual User Manual

Page 91

3-49

6036, 6042, 8042, 10042, 10054

Boom

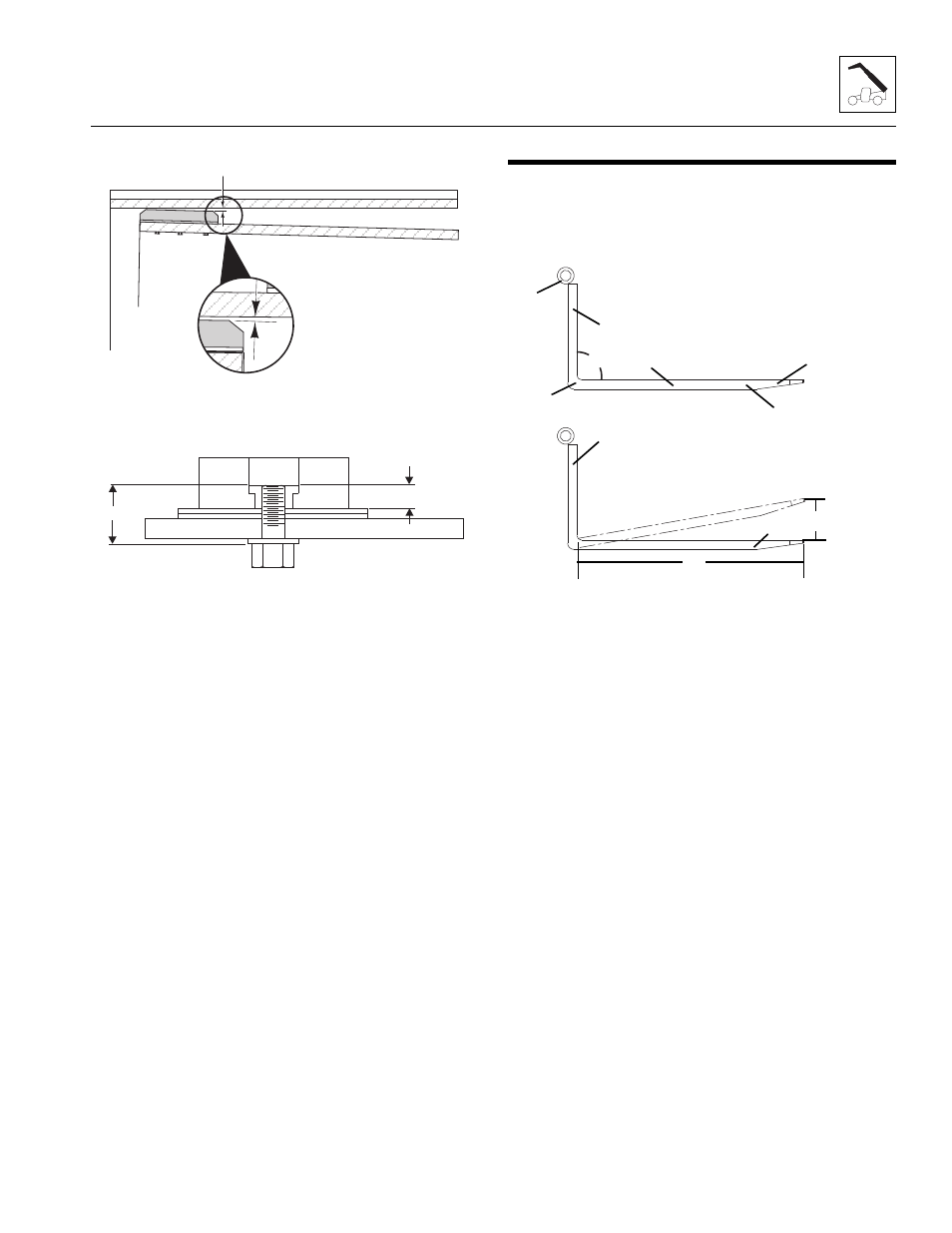

• Maintain a total boom section clearance (5) of

0.070 - 0.130 in (1,78 - 3,30 mm) both the horizontal

and vertical directions.

• The length of the wear pad bolt depends on the

number of shims, spacers and washers being used.

• The thickness of each threaded wear pad insert is

0.562 in (14,27 mm) (A).

• The bolt length should be determined by measuring

the distance from the face of the insert to the face of

the boom (B) including any spacer, shim(s) and

washer(s).

• Bolt thread engagement in the wear pad insert

should be 0.235 - 0.315 in (5,98 - 8,0 mm).

• One or two hardened washers are to be used on

each wear pad bolt except where noted otherwise.

DO NOT use more than two hardened washers.

• Use only one hardened washer if mounting bolts are

recessed.

• Wear Pad Bolt Torque: 3/8-16 Bolt, 31 lb-ft (42 Nm)

• Torque wear pad bolts after shimming is completed.

• Lubricate the face and pockets of each wear pad

after being installed.

Boom Section Wear Pad Pathway Lubrication:

• Clean and lightly grease all wear pad pathways with

Mystik Tetrimoly grease.

• Clean and lightly grease the hose carrier guide bar

pathways with Mystik Tetrimoly grease.

3.10

FORKS

Forks should be cleaned and inspected prior to being

attached to carriage. If the following criteria is not met,

forks must be removed from service immediately.

Daily Inspection

1. Inspect forks (4) for cracks, paying special attention

to heel (5) and mounting tubes (6).

2. Inspect forks for broken or bent tips (7) and twisted

blades (8) and shanks (9).

Yearly Inspection

1. Straightness of the upper face of blade (8) and the

front face of shank (9) should not exceed 0.5 percent

of the length of blade or height of shank.

2. Angle (10) between upper face of blade and front

face of shank should not exceed 93 degrees.

3. Thickness of blade (13) and shank (14) should not

be reduced to 90 percent of original thickness.

4. Ensure fork length (12) is adequate for intended

loads.

5. Fork markings should be legible, re-stamp if

required.

6. Compare fork tips (11) when mounted on a carriage.

Maximum difference in height of fork tips is 3 percent

of the length of the blade (13).

5

MY3620

A

B

MH6460

6

5

9

10

8

4

7

14

13

12

11