8 unloader valve (6036 & 6042 only), Unloader valve (6036 & 6042 only) – SkyTrak 6036 Service Manual User Manual

Page 180

Hydraulic System

8-28

6036, 6042, 8042, 10042, 10054

b. Steer Select Manifold and Valve Disassembly,

Cleaning, Inspection and Assembly

1. Place the steer select assembly on a suitable

work surface.

2. Separate the steer select valve from the manifold by

removing the four socket head capscrews. Discard

the four o-rings.

3. Remove the solenoid valves and cartridges from the

steer select housing.

4. Clean all the components with a suitable cleaner

before inspection.

5. Inspect the solenoid cartridges for proper operation.

Check by shifting the spool to ensure that it is

functioning properly. Check that the spring is intact.

Inspect the cartridge interior for contamination.

6. Inspect internal passageways of the steer select

manifold and valve for wear, damage, etc. If inner

surfaces of the manifold DO NOT display an ultra-

smooth, polished finish, or components are

damaged in any way, replace the manifold or

appropriate part. Often, dirty hydraulic fluid causes

failure of internal seals and damage to the polished

surfaces within the secondary function manifold.

Note: ALWAYS replace seals, o-rings, gaskets, etc.,

with new parts to help ensure proper sealing and

operation. Lubricate seals and o-rings with clean

hydraulic oil.

7. Install the solenoid valves and cartridges in the steer

select housing.

8. Attach steer select valve to the manifold using four

new, oiled o-rings and four socket head capscrews.

c. Steer Select Valve and Manifold Installation

1. Install the steer select valve to the mounting plate on

the frame using two capscrews.

2. Connect all the previously labeled hydraulic hoses,

fittings, solenoid wire terminal leads, etc., to the

steer select valve.

3. Check the routing of all hoses, wiring and tubing for

sharp bends or interference with any rotating

members, and install tie wraps and/or protective

conduit as required. Tighten all hose clamps.

4. Properly connect the battery.

5. Remove the Do Not Operate Tags from both the

ignition key switch and the steering wheel.

6. Start the engine and run at approximately 1/3-1/2

throttle for about one minute without moving the

machine or operating any hydraulic functions.

7. Inspect for leaks and check the level of the hydraulic

fluid in the reservoir. Shut the engine OFF.

Note: Check for leaks and repair as required before

continuing. Add hydraulic fluid to the reservoir as

needed.

8. Wipe up any hydraulic fluid spillage in, on, near and

around the machine, work area and tools.

9. Install the transmission covers.

10. Close and secure the rear door.

d. Steering Test

Refer to Section 8.4.1, “Hydraulic Pressures.”

1. Conduct a pressure check of the steering

hydraulic circuit.

2. Check each steering mode for proper function.

8.7.8

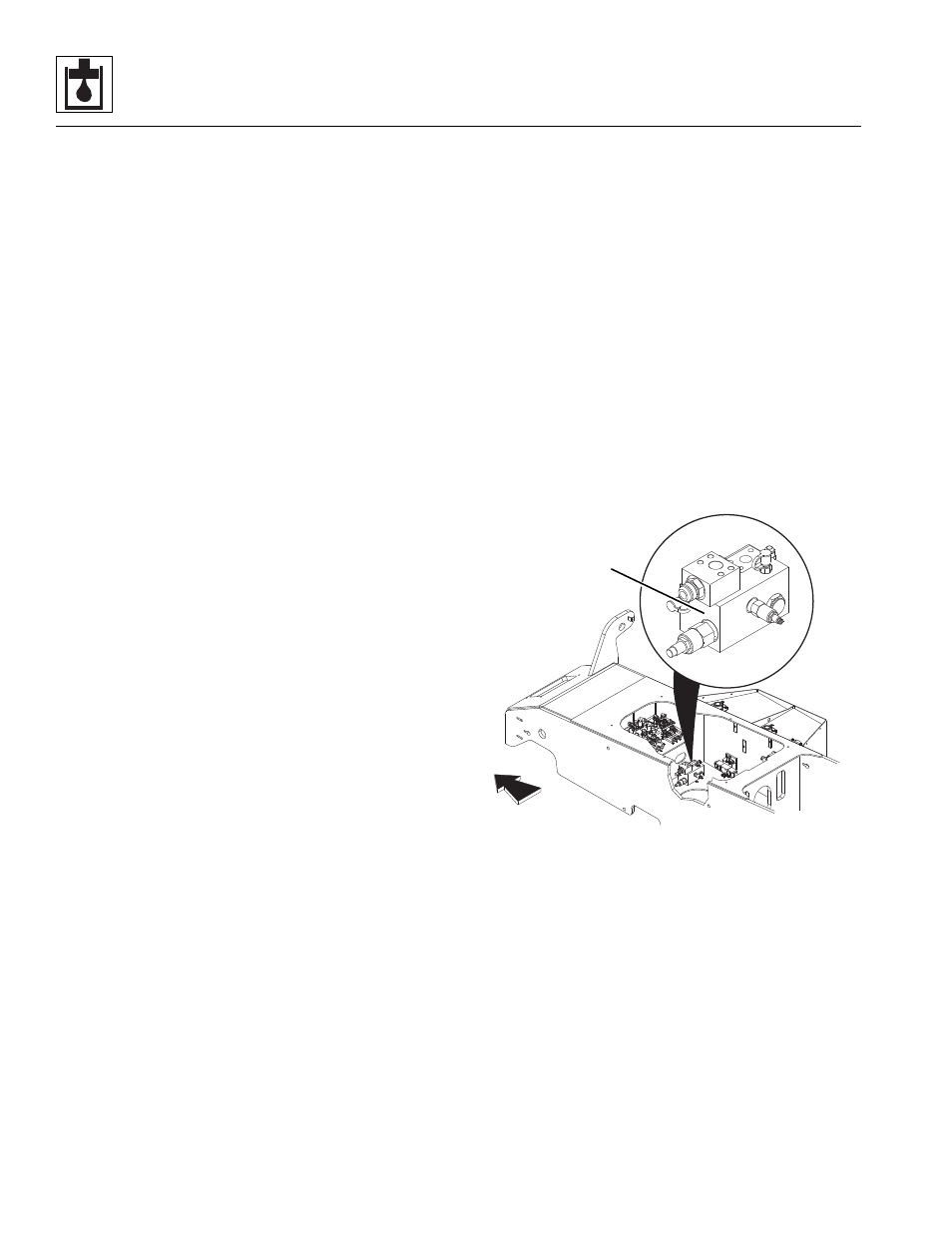

Unloader Valve (6036 & 6042 only)

The unloader valve (1) creates system pressure and

distributes the hydraulic fluid for various machine

functions via its load sense, by to tank (via the oil cooler),

and primary and secondary valve ports. The unloader

valve is secured to the frame toward the front of the

machine near the main control valve.

a. Unloader Valve Removal

1. Park the machine on a firm, level surface, level the

machine, fully retract the boom, raise the boom, place

the transmission control lever in (N) NEUTRAL,

engage the park brake and shut the engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and the steering wheel, stating that the

machine should not be operated.

MA8391

1