11 towing a disabled machine, Towing a disabled machine – SkyTrak 6036 Service Manual User Manual

Page 125

5-19

6036, 6042, 8042, 10042, 10054

Axles, Drive Shafts, Wheels and Tires

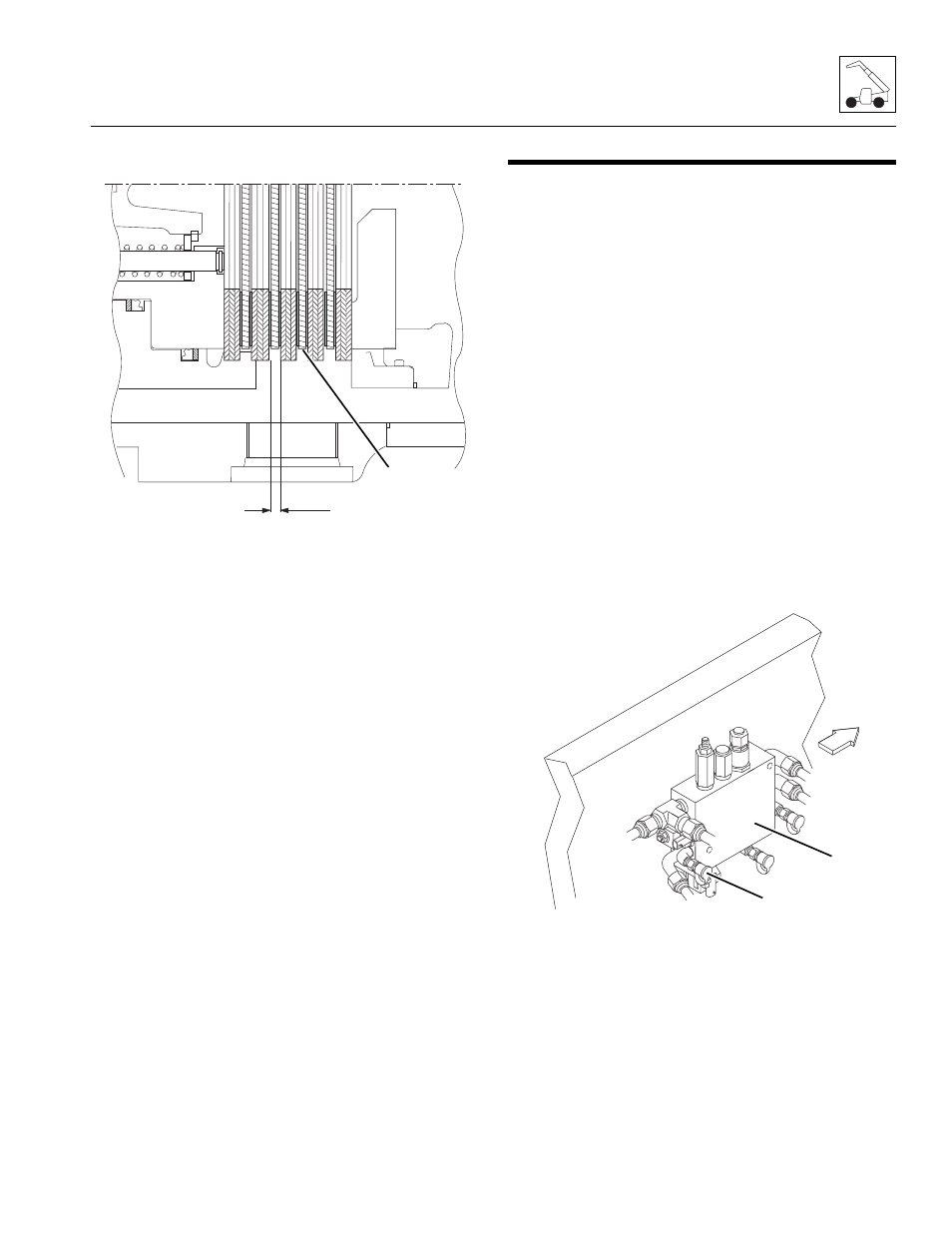

3. Using a feeler gauge, check thickness of lined/inner

disc (6). If thickness is less than or equal (

≤)

to

3.75mm, replace the lined/inner discs.

Note: If discs are worn beyond their tolerance, discs

must be replaced on both sides of axle at the same time.

4. Repeat step 3 for other side of axle.

5. Fill the axle with Mobilfluid 424

®

Tractor Hydraulic

Fluid (ISO 46) through the axle fill hole until the oil

level is even with both axle level holes. Fill the axle

slowly, allow time for the oil to run across the

differential.

6. Reassemble the level plugs using new o-rings.

7. Install the axle fill plug into axle housing.

5.11

TOWING A DISABLED MACHINE

Towing a disabled machine should only be attempted as

a last resort, after exhausting all other options. Make

every effort to repair the machine, and move it under its

own power. Towing the machine improperly can result in

damage to the machine drivetrain.

Note: In the event the machine is disabled and cannot

be moved under engine power, the situation must be

properly evaluated and dealt with on an individual basis.

Contact your local JLG distributor for specific instructions

for your particular situation.

If it is necessary to tow the machine a short distance to

avoid a potentially hazardous situation such as being in

an unsafe area on the worksite or on a roadway, prepare

the machine for towing as follows:

1. Remove the load from the machine.

2. Block all four wheels to help prevent the machine

from moving after the parking brake is disabled.

3. Remove the transmission covers.

4. Position the towing vehicle in place. Attach any

chains needed to secure the disabled machine.

MAQ1000

6

7

OA1231

5

6

FRONT OF

MACHINE

6036 & 6042