7 boom extend and retract chains, 1 boom chain inspection, Boom extend and retract chains – SkyTrak 6036 Service Manual User Manual

Page 70: Boom chain inspection, Warning

Boom

3-28

6036, 6042, 8042, 10042, 10054

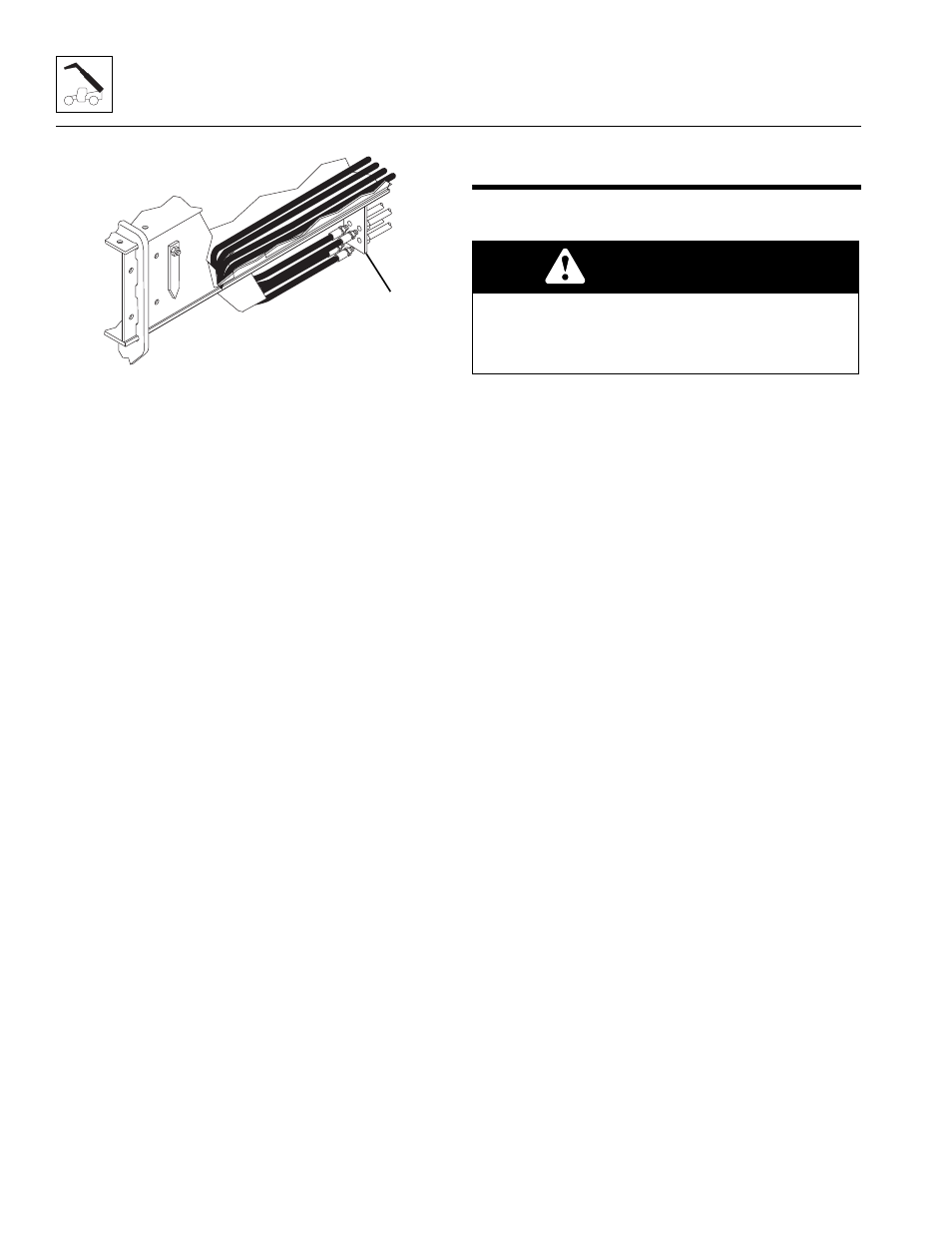

29. At the front of the first boom section, assemble the

hose assemblies and tube assemblies to the

mounting plate (6).

Note: Where the hose assemblies come out of the outer

boom, lubricate the radius in the first boom section with

soap and water to allow proper tensioning of hoses.

30. Install the quick attach and Attachment Tilt cylinder

to the front of the boom. Refer to Section 3.8.2,

“Quick Attach Installation.”

31. Uncap and connect the previously labeled hoses to

the Attachment Tilt cylinder.

32. Properly connect the battery.

33. Remove the Do Not Operate Tags from both the

ignition key switch and the steering wheel.

34. Start the engine and operate all boom functions

several times. Check the chain tension again and

adjust as necessary. Check for leaks, and check the

hydraulic fluid level in the tank; add fluid if required.

35. Clean up all debris, hydraulic fluid, etc., in, on, near

and around the machine.

36. Install the rear cover to the boom.

37. Close and secure the rear door.

3.7

BOOM EXTEND AND RETRACT

CHAINS

3.7.1

Boom Chain Inspection

Under normal operating conditions the boom extend

chains will need to be inspected every

250

hours of

operation. The retract chains need to be exposed and

inspected every 1000 hours of operation. Environmental

conditions and dynamic impulse/shock loads can

drastically affect normal operating conditions and require

more frequent inspection intervals.

Environments in which material handling machines

operate can vary widely from outdoor moisture to

temperature to mildly corrosive or highly corrosive

industrial atmospheres, in addition to abrasive

exposures such as sand and grit. Some effects can be

as follows:

• Moisture - Corrosive rusting reduces chain

strength by pitting and cracking.

• Temperature - Low temperature reduces chain

strength by embrittlement. Going in and out of

cold storage results in moisture from

condensation.

• Chemical Solutions or Vapors - Corrosive attack

on the chain components and/or the mechanical

connections between the chain components.

Cracking can be (and often is) microscopic.

Going from microscopic cracking to complete

failure can be either abrupt or may require an

extended period of time.

• Abrasives - Accelerated wearing and scoring of

the articulating members of the chain (pins an d

plates), with a corresponding reduction in chain

strength. Due to the inaccessibility of the bearing

surfaces (pin surfaces and plate apertures),

wear and scoring are not readily noticeable to

the naked eye.

MH1451

6

WARNING

Worn pins, stretched or cracked links or corrosive

environments can cause chain failure. A chain failure

could result in uncontrolled boom movement, loss of

load or machine instability.