4 hydraulic oil reservoir replacement, 6 hydraulic system pump, 1 pump replacement – SkyTrak 6036 Service Manual User Manual

Page 173: Hydraulic system pump, Hydraulic oil reservoir replacement, Pump replacement

8-21

6036, 6042, 8042, 10042, 10054

Hydraulic System

7. Install the four previously removed nuts securing the

hydraulic filter assembly to the hydraulic reservoir.

Torque the nuts to 75 lb-in (8.5 Nm).

8. Wipe up any hydraulic fluid spillage in, on, near and

around the machine and the work area.

8.5.4

Hydraulic Oil Reservoir Replacement

The hydraulic reservoir and the fuel tank are one unit and

are removed together. Refer to Section 7.6.2, “Fuel/

Hydraulic Oil Tank,” for information on hydraulic

reservoir/fuel tank replacement.

8.6

HYDRAULIC SYSTEM PUMP

For internal service instructions contact your local

authorized service distributor.

8.6.1

Pump Replacement

a. Pump Removal

1. Park the machine on a firm, level surface, level the

machine, fully retract the boom, raise the boom, place

the transmission control lever in (N) NEUTRAL,

engage the park brake and shut the engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and the steering wheel, stating that the

machine should not be operated.

3. Temporarily block up or support the raised boom.

4. Open the rear door. Allow the system fluids to cool.

5. Properly disconnect the battery.

6. Drain the hydraulic reservoir. Refer to Section 8.5.1,

“Hydraulic Oil Reservoir Draining.”

7. Thoroughly clean pump (3) and surrounding area,

including all hoses and fittings before proceeding.

8. Label, disconnect and cap the hydraulic hoses

attached to the pump.

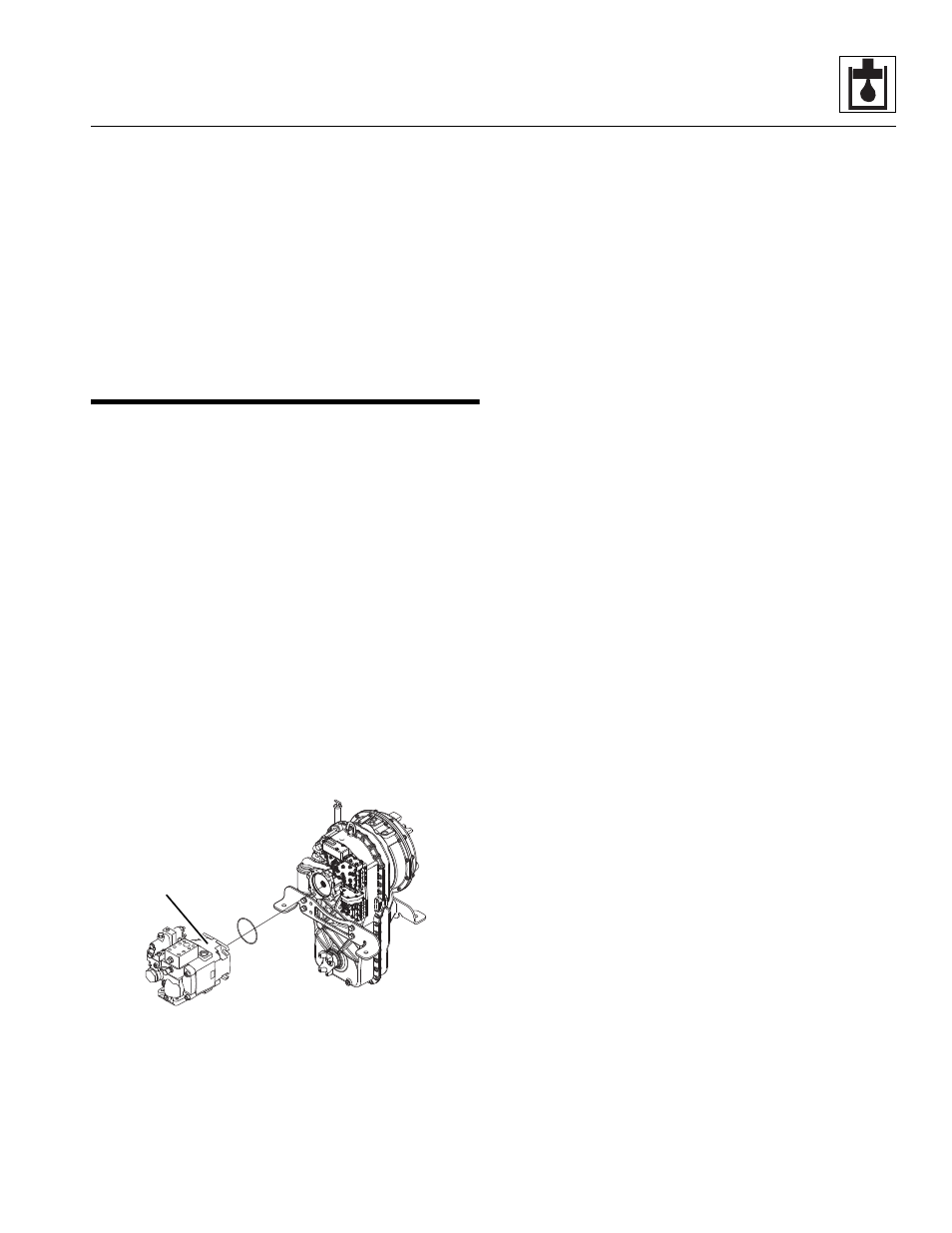

9. Remove the bolts, lockwashers and washers

securing the pump to the transmission. Remove the

o-ring located between the transmission and the

pump. Wipe up any hydraulic oil spillage.

10. Remove the hydraulic fittings from the pump to use

for later installation.

Note: Before removing any fittings from the pump, note

their orientation to ensure correct installation.

Note: DO NOT disassemble the operating pump. The

pump is pre-set from the manufacturer. Any adjustments

or repairs performed by anyone other than an authorized

dealer could void the warranty.

b. Pump Installation

1. Install the fittings on the pump in the same

orientation as noted during removal.

2. Place the pump and a new, oiled o-ring into position

on the transmission. Align the pump shaft with the

internal transmission gear, so that the machined

teeth mesh together.

3. Align the bolt holes with the pump mount holes.

Secure the pump to the transmission with the

previously used hardware.

4. Uncap and connect the previously labeled hydraulic

hoses to their appropriate locations.

5. Fill the hydraulic reservoir. Refer to Section 8.5.2,

“Hydraulic Oil Reservoir Filling.”

6. Prime the pump by filling the case drain port with fresh,

filtered hydraulic oil from a clean container before

installing the case drain connector and hose.

7. Check all routing of hoses and tubing for sharp

bends or interference with any rotating members. All

tube and hose clamps must be tight.

8. Properly connect the battery.

9. Remove the Do Not Operate Tags from both the

ignition key switch and the steering wheel.

10. Close and secure the rear door.

11. Start engine and run at approximately one-third to

one-half throttle for about one minute without moving

the machine or operating any hydraulic functions.

12. Inspect for leaks and check all fluid levels. The

hydraulic reservoir oil level must be to the middle of

the sight gauge.

c. Pump Test

1. Refer to Section 8.3.1, “Pressure Checks and

MH6490

3