2 installing wheel and tire assembly onto machine, 10 brakes, 1 brake disc inspection – SkyTrak 6036 Service Manual User Manual

Page 124: Brakes, Installing wheel and tire assembly onto machine, Brake disc inspection, Section 5.10.1, “brake disc inspection

Axles, Drive Shafts, Wheels and Tires

5-18

6036, 6042, 8042, 10042, 10054

5.9.2

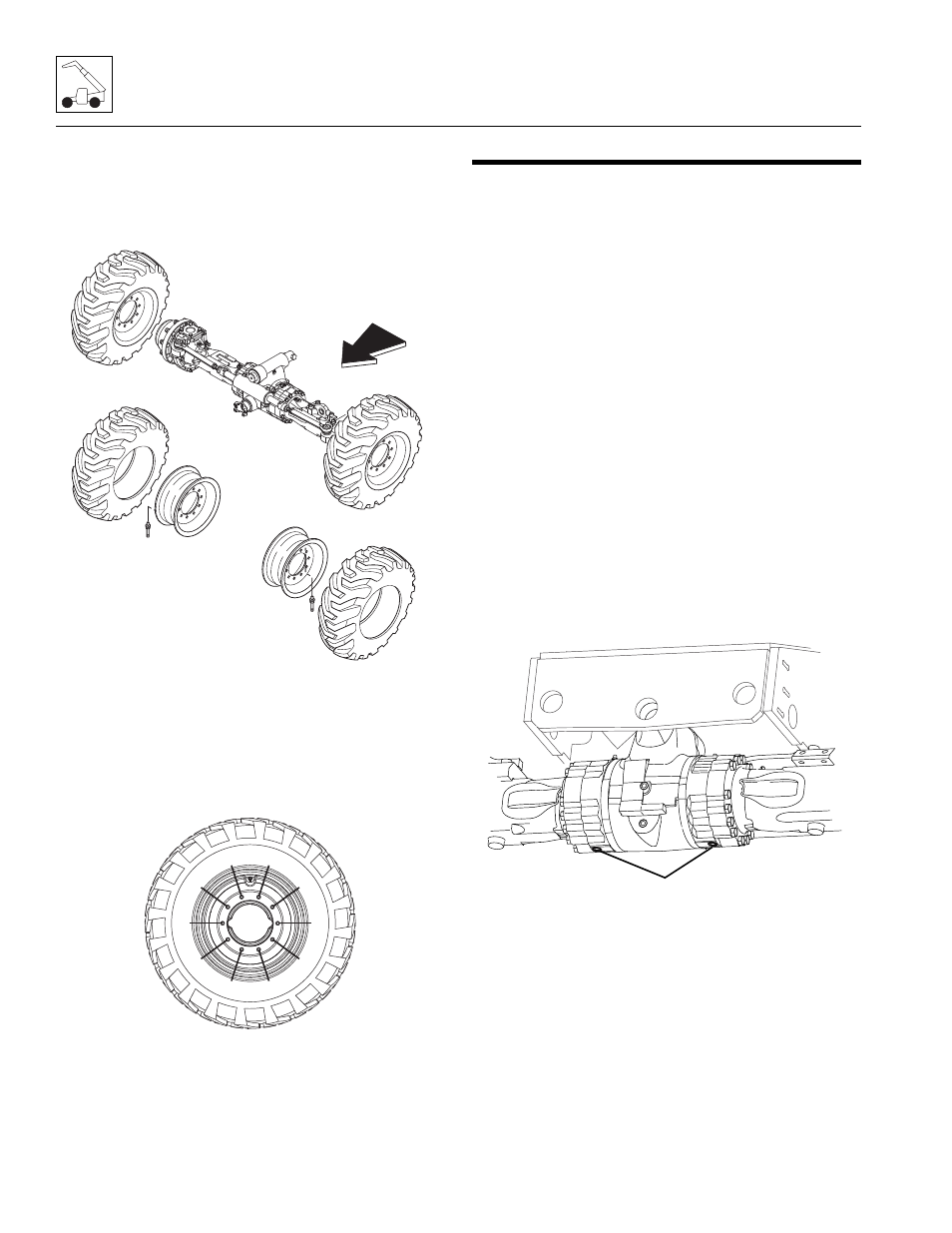

Installing Wheel and Tire Assembly

onto Machine

Note: The wheel and tire assemblies must be installed

with the directional tread pattern “arrows” facing in the

direction of forward travel.

1. Position wheel onto studs on wheel end of axle.

2. Install wheel lug washers.

3. Start all nuts by hand to prevent cross threading. DO

NOT use a lubricant on threads or nuts.

4. Tighten lug nuts in an alternating pattern as

indicated in figure. Torque to 430–470 lb-ft

(583–637 Nm).

5. Remove machine from supports.

5.10

BRAKES

5.10.1

Brake Disc Inspection

A brake lining wear measurement on service brake

(multi-disc brake) gives just limited information about the

overall condition of the multi-disk package–without

disassembly of the output.

Check the brake discs for wear every 1,000 hours of

operation or yearly. Additionally, check brake discs if

braking behavior has changed in any of following ways:

• Brake noises

• Reduced braking power

• Changed deceleration

• Changed brake oil level

• Changed braking pressure

Wear measurement must be carried out on both output

sides of axle!

For more information on brake disc inspection, refer to

the appropriate axle repair manual.

1. Block all four wheels to help prevent the machine

from moving.

2. Place a suitable receptacle under axle drain plug (5).

Remove drain plug and allow axle oil to drain into

receptacle. Transfer used axle oil into a suitable

covered container, and label container as “Used Oil.”

Dispose of used oil at an approved recycling facility.

MAQ0990

TREAD “ARROWS” MUST

POINT FORWARD

INSTALL TIRES ONTO

WHEELS TO ROTATE IN

PROPER DIRECTION

OY1220

1

2

3

4

5

6

7

8

9

10

MAQ0960

5